Automated snow removal tracking system

a tracking system and snow removal technology, applied in snow cleaning, data processing applications, instruments, etc., can solve problems such as inability to find oversight, property can be overlooked, and office staff generally do not know,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

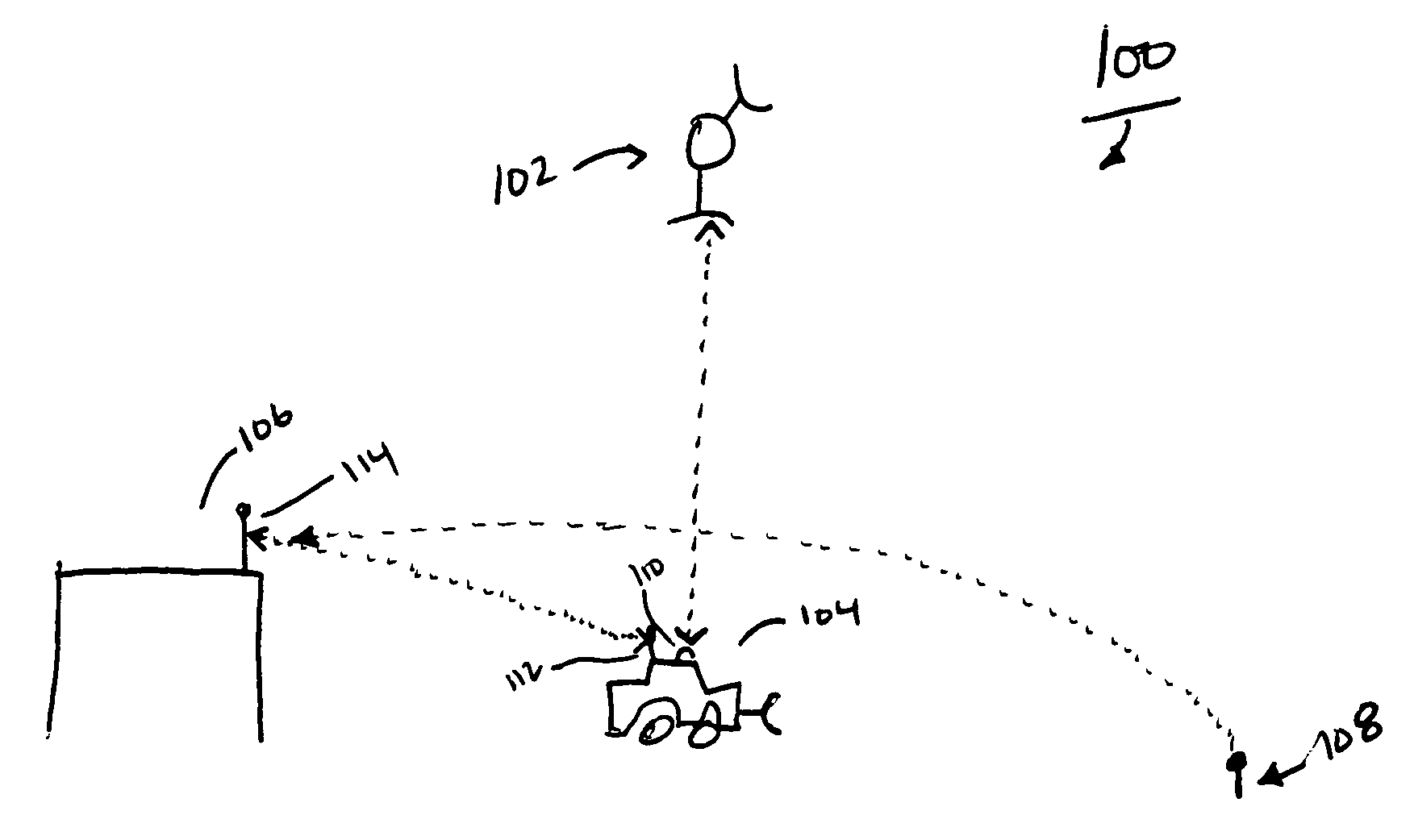

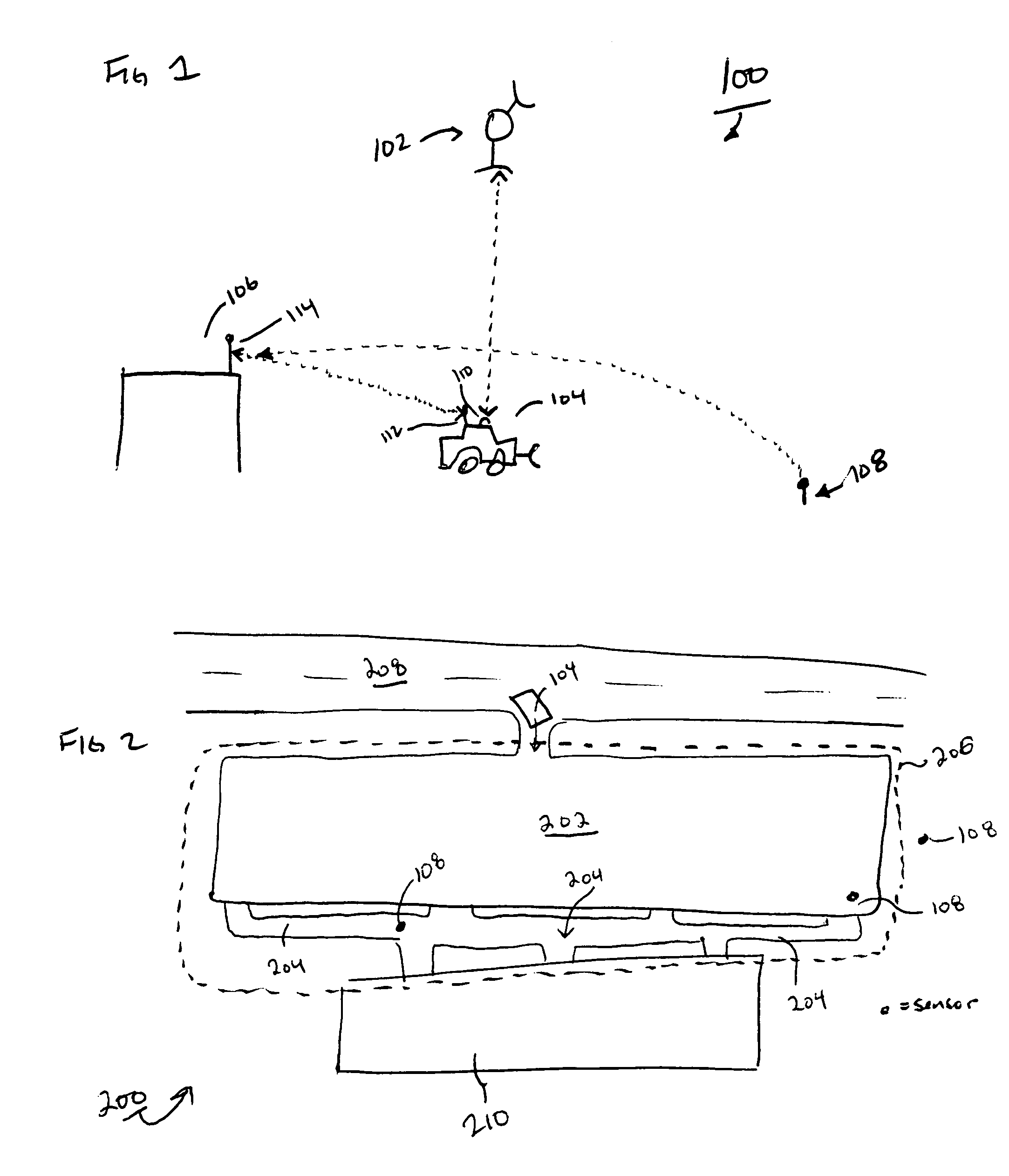

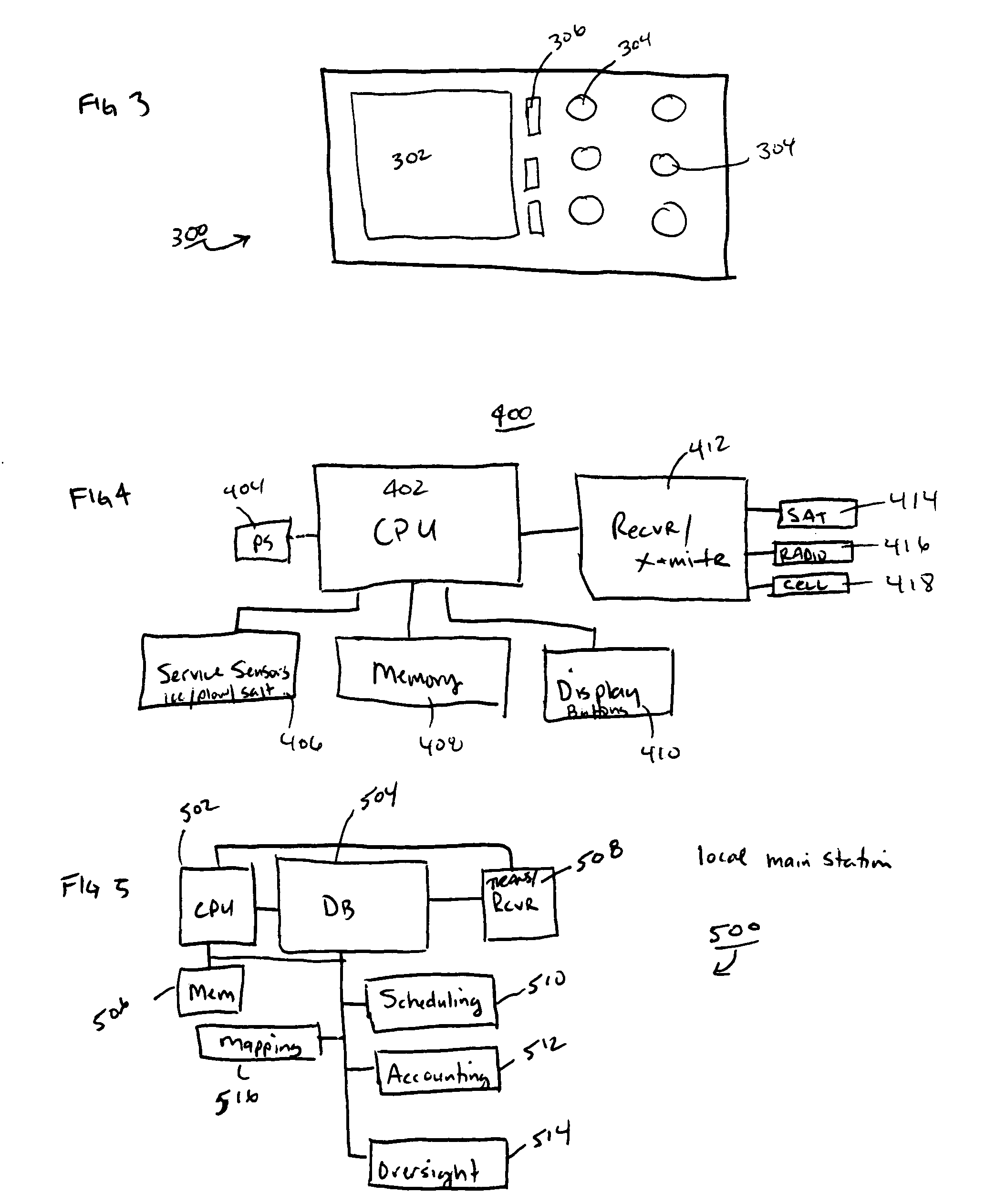

[0021]Embodiments of the invention generally provide an automated snow removal tracking system. The tracking system of the invention has a GPS backbone, i.e., the tracking system of the invention uses GPS technology to support the tracking functions of the invention. The GPS technology is generally used to determine when a snow removal crew arrives at a specific property to begin snow removal work, the duration and / or type of snow removal work being conducted at the property, the time when the snow removal crew leaves the property where the snow removal work has been completed, the time associated with travel between snow removal locations, the routes used for traveling between the respective snow removal locations, and / or any other location based operations that may be determined through GPS based technology. The GPS data / information is also used to verify scheduling of crews for particular properties, to track services provided at the particular properties, and to interface with b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com