Artificial lung

A technology of artificial lung and diaphragm, applied in the field of artificial lung

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

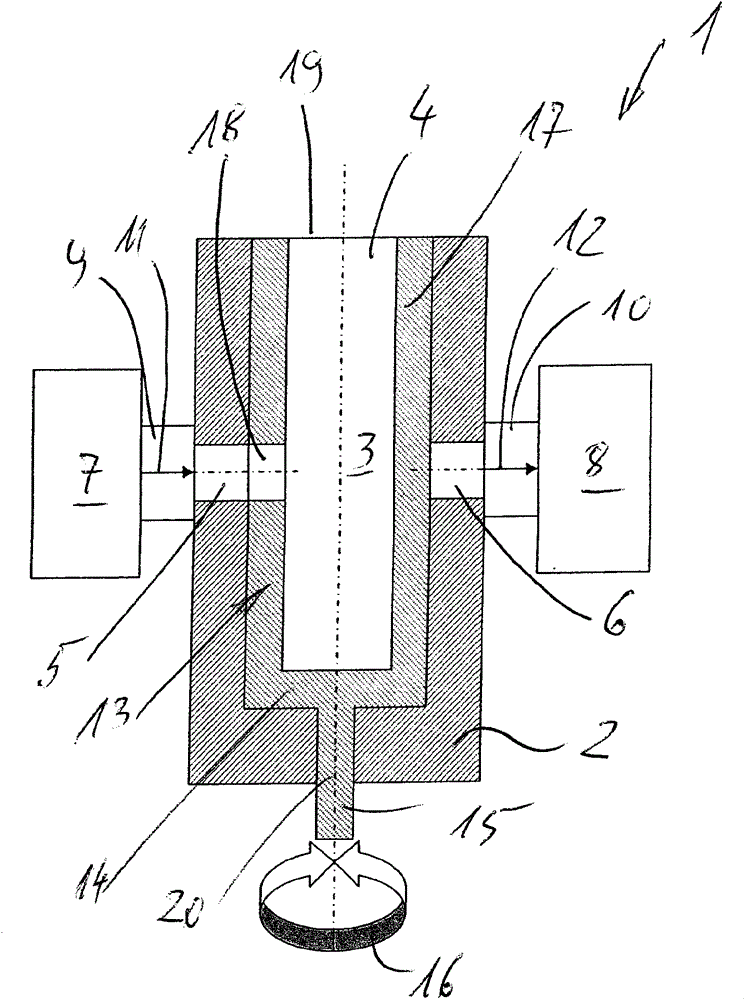

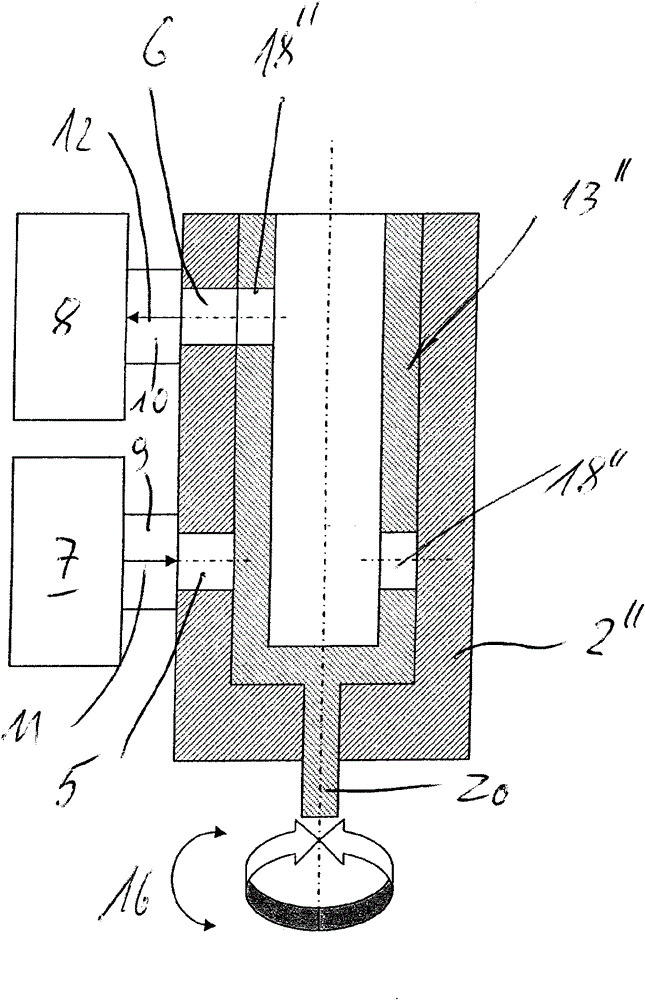

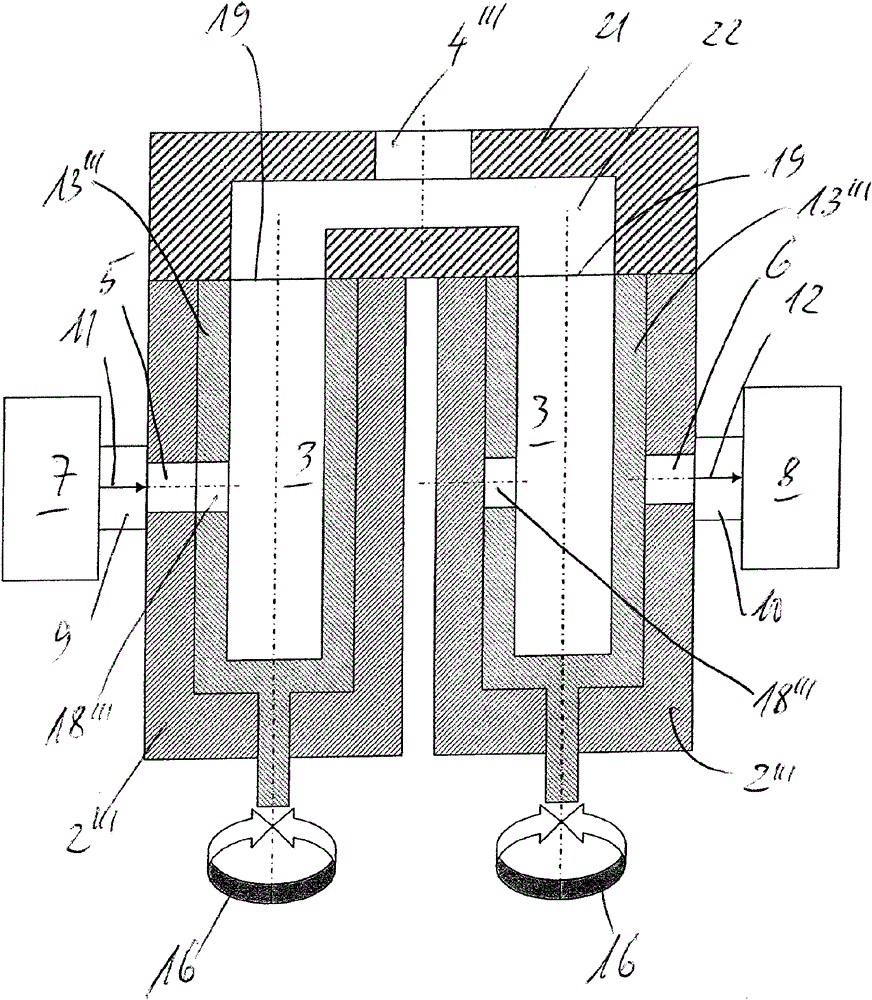

[0034] exist figure 1 The first embodiment of the artificial lung 1 , shown in axial longitudinal section, is used to simulate user loads when testing respiratory protective equipment, in particular compressed-air respiratory protective equipment. For the purpose of the test, the manufacturer establishes a rated value based on the compressed-air respirator to be tested, which must be followed in order to pass the test, especially for compressed-air respirators with automatic lung systems.

[0035] The artificial lung 1 comprises a tubular housing 2 which encloses a lung chamber 3 for breathing air. On the upper side 19, the tubular housing 2 comprises a connection 4 for supplying the breathing air present in the lung chamber 3 to a not shown breathing connection, in particular also not shown, of the respiratory protective device to be tested. Breathing interface of the lung robot. The housing 2 is additionally provided with an inlet 5 and an outlet 6 for breathing air. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com