Structure of wire rope reel

A wire rope reel and body technology, which is applied in the field of hoisting and conveying machinery, can solve the problems of high service life and use cost, scrapping of reel parts, etc., and achieve the effect of high service life and use cost.

Inactive Publication Date: 2012-12-05

张家升

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The object of the present invention is to provide a structure of a steel wire rope drum, which overcomes the defect that the entire drum part must be scrapped due to the surface wear of the existing steel wire rope drum, and the resulting service life and use cost are relatively high Defects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

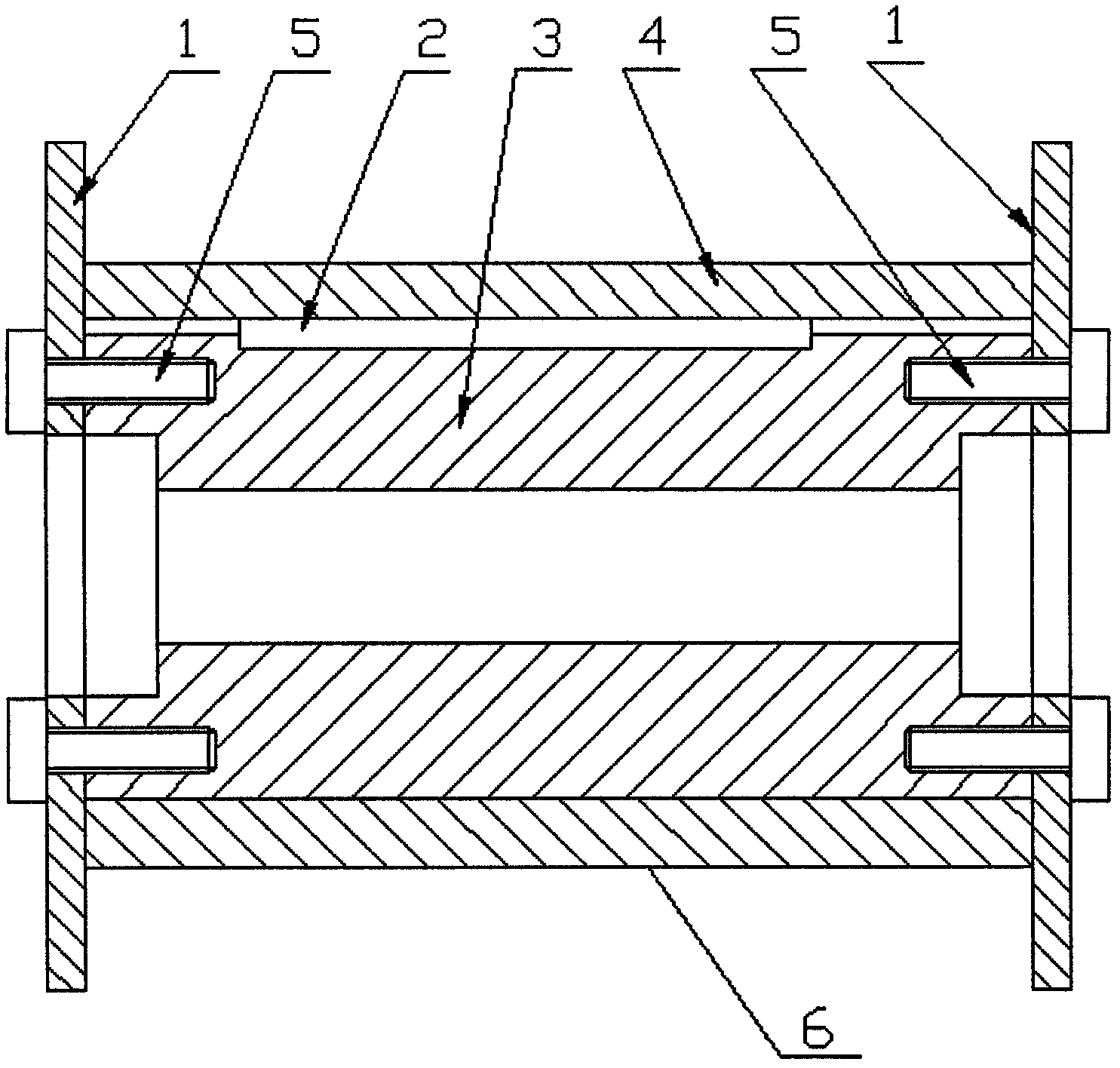

[0008] The wire rope reel has a wear-resistant sleeve (4) made of a higher hardness material, on the outer circle of the body shaft sleeve (3), a wear-resistant sleeve (4) is set, the body shaft sleeve (3) and the wear-resistant sleeve ( 4) are connected by keys (2), and the two flanges (1) are installed at both ends of the main body shaft sleeve (3) with bolts (5).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a structure of wire rope reel, including a wear-proof casing made of high hardness material covering the excircle of the shaft sleeve body and connected with the shaft sleeve body by key joint consisting of two flange bolts fixed on both ends of the shaft sleeve body. The structure can avoid the dumping of the whole reel due to the abrasion of the reel surface and solve the defects of short service life and high use cost.

Description

Technical field: [0001] The invention relates to a structure of a reel, in particular to a structure of a steel wire rope reel, and belongs to the technical field of winch transportation machinery. Background technique: [0002] The reel is an important part of the hoisting and transportation machinery. During the working process, the reel often needs to repeatedly wind the wire rope and bear the tension of the wire rope. Therefore, the surface of the reel is easy to be worn by the wire rope. To a certain extent, the entire reel must be scrapped, so the existing reel has the disadvantages of high service life and high cost of use. Invention content: [0003] The object of the present invention is to provide a structure of a steel wire rope drum, which overcomes the defect that the entire drum part must be scrapped due to the surface wear of the existing steel wire rope drum, and the resulting service life and use cost are relatively high Defects. [0004] The technical s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B66D1/30

Inventor 张家升

Owner 张家升

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com