Structure of electric bicycle wheel

A technology for electric bicycles and wheels, which is applied to the rigid support of the hub, vehicle components, bearing components, etc., and can solve the problems of easily damaged hubs and scrapped wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

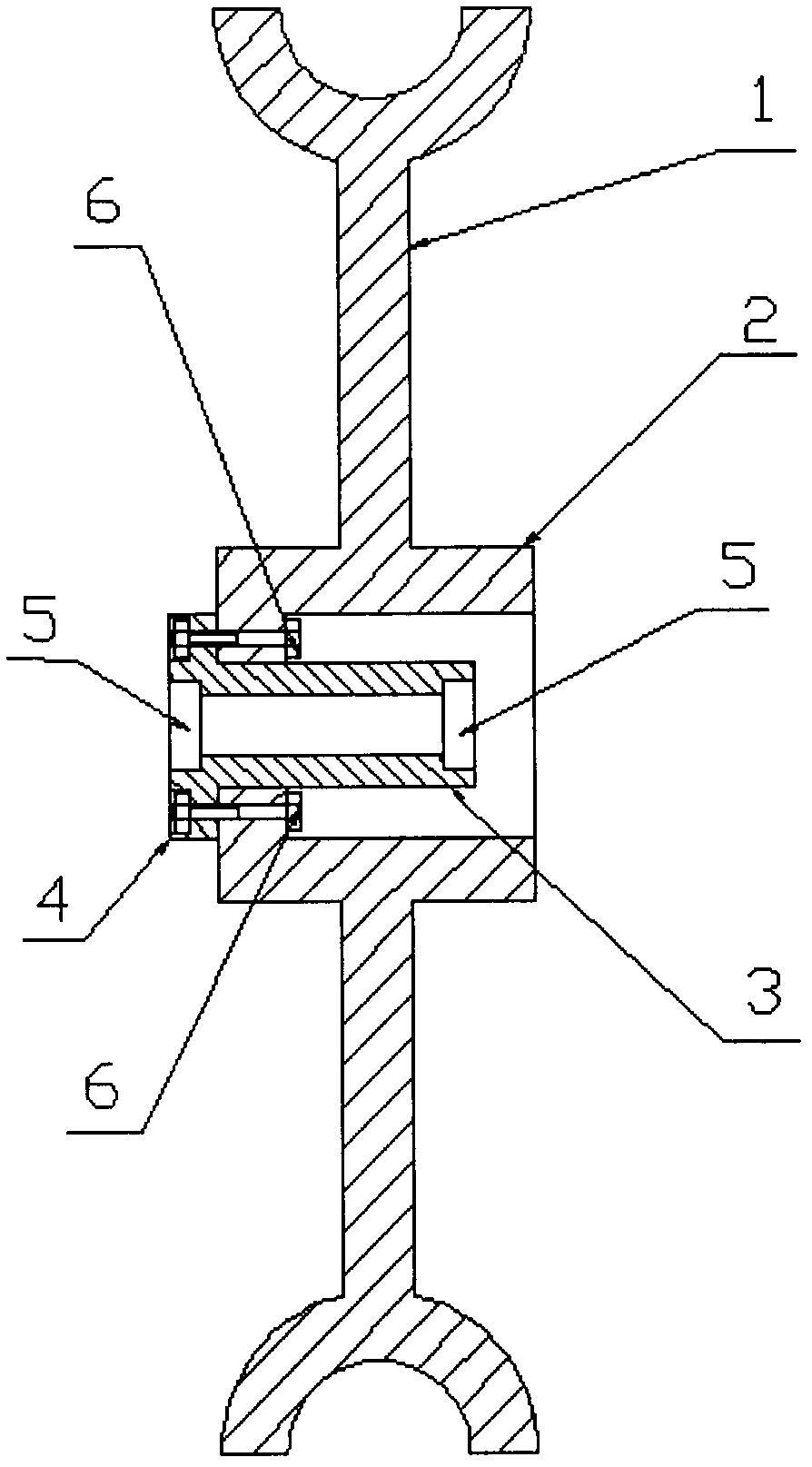

[0008] With reference to accompanying drawing of the present invention, the structure of a kind of electric bicycle wheel of the present invention, it comprises wheel spoke (1), wheel hub (2), and described wheel hub (2) is in the central part of wheel spoke, and wheel spoke (1) and wheel hub ( 2) make an integral structure between them, and install an insert (3) on the central axis of the hub (2) of the wheel. The end of the insert (3) has a flange (4), The two ends of the central hole at both ends of the insert (3) are provided with bearing holes (5) for installing bearings, and the insert (3) is installed and fixed with the hub (2) by bolts (6) through the flange (4) at its end together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com