Portable GC Capillary Column Modules

A capillary column and gas chromatography technology, which is applied in the field of gas chromatography analysis and testing, can solve the problems of capillary column and heating wire winding methods, such as complex winding, high price, and inability to disassemble, so as to reduce heat radiation loss and prevent convective heat loss , The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

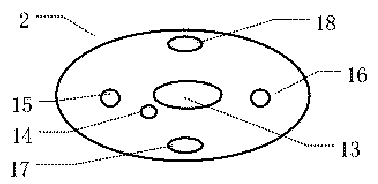

[0101] Such as Figure 1A , Figure 1B As shown, in this embodiment 1, the capillary column 6 is described by taking an MXT column with a specification of 5 m×0.25 mm i.d.×0.25 μm as an example. Due to the good elasticity of the capillary column 6, a thinner capillary column skeleton can be selected. The cap 2 is integrally connected with the capillary column framework 1 on the upper end surface of the capillary column framework 1 . The heating device 3 is inserted in the cavity of the capillary column framework 1 and coupled with the capillary column framework 1 through a thermal conductive paste 5 . The temperature measuring device 4 is closely attached to the inner wall of the capillary skeleton 1, and the heating device 3 and the temperature measuring device 4 are respectively drawn from the heating device outlet port 13 and the temperature measuring device outlet port 14 on the cap 2 and connected to the power supply and the temperature controller. The precise temperatu...

Embodiment 2

[0103] Similarly, this embodiment adopts Figure 1A and Figure 1B For the capillary column module as shown, the difference between this embodiment and Embodiment 1 is that, in this embodiment, the capillary column 6 is a quartz column with a specification of 30 m×0.25 mm i.d.×0.25 μm. All the capillary columns 6 are long in length and poor in elasticity, so the size of the capillary column skeleton 1 is larger than that of the embodiment 1. Apart from that, all other devices and their assembly in this embodiment are completely the same as those in Embodiment 1, and will not be repeated here. The total volume of the module in this embodiment is about: 100mm*100mm (2R*H).

Embodiment 3

[0105] In this embodiment, it is an application embodiment of expanding two modules of the present invention into a comprehensive two-dimensional gas chromatography module.

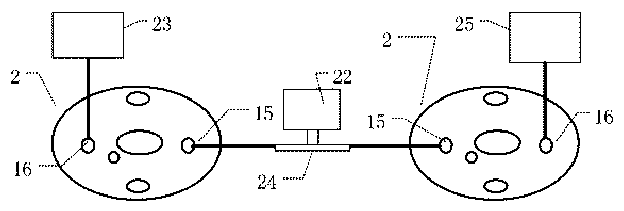

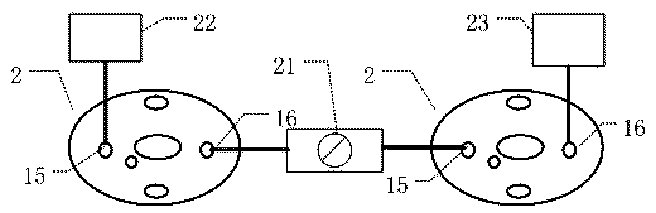

[0106] Figure 2A and Figure 2B It is a schematic diagram of an application embodiment in which the module of the present invention is extended to comprehensive two-dimensional or tandem chromatography in this embodiment. Such as Figure 2A and Figure 2B as shown, Figure 2A A single module in is Figure 1A and Figure 1B module shown. The capillary column properties of the two module assemblies are different. Use a two-pass modulator 21 to connect the first module (in Figure 2A in the left module) the capillary column outlet port 16 is connected to the second module (in the Figure 2A The capillary column inlet port 15 of the module on the right is connected in series, the capillary column inlet port 15 of the first module is connected to the injector 22, and the capillary column outlet port 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com