Electric pole hole digging device

A pole hole and pole technology, which is applied in the field of wire and line laying equipment, can solve the problems of increasing excavation costs and affecting the progress of the project, and achieves the effects of light weight, flexible use and obvious economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments and illustrations.

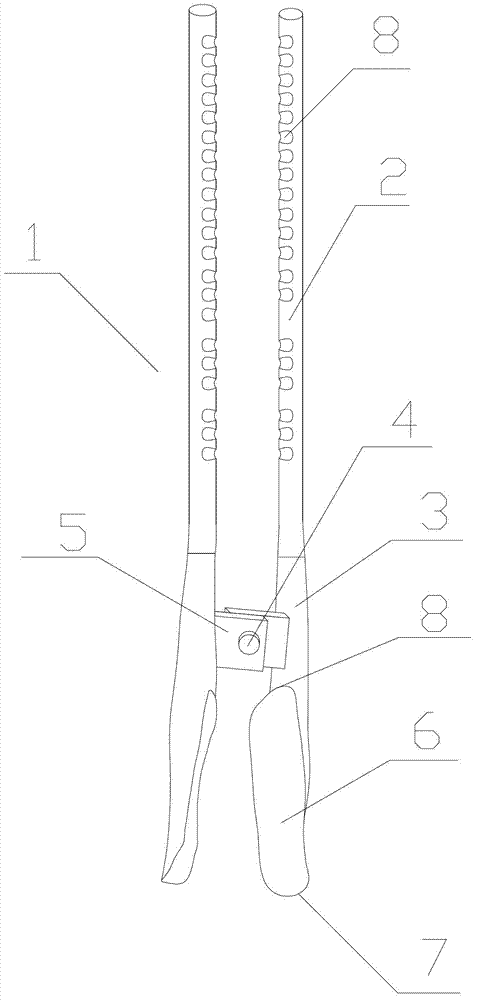

[0026] Such as figure 1 As shown, an excavator for a pole hole, the main body of which is two shovel bars 1 arranged opposite to each other. The shovel bar 1 includes an upper handle 2 and a spade head 3 fixedly arranged at the lower end of the handle 2 by welding. A connection block 5 is provided on the inner surface of the top of the spade head 3, and the two spade bars 1 are flexibly connected through the connection block 5 through the screw rod 4. The bottom 7 is arc-shaped, which can be easily inserted into the soil and saves labor. The spade face 6 of the spade head 3 is rolled up on both sides and has a hollow cavity in the middle, and the top 8 of the spade face 6 is wider than the bottom. 7. It is convenient to excavat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com