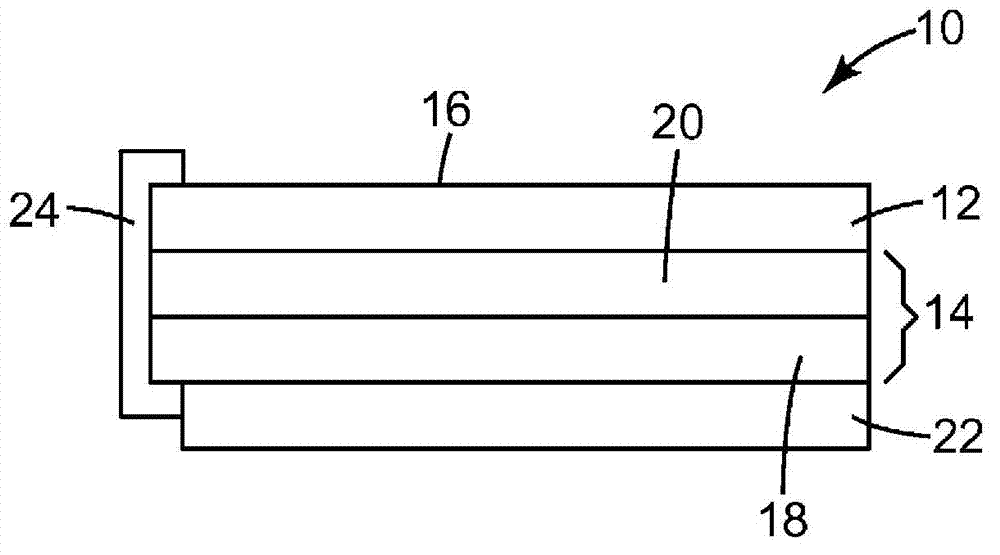

Low ghosting dry erase article and use thereof

A product, dry-erase technology, used in reusable writing boards, printing and other directions, can solve the problem of difficult to erase, and achieve good drag resistance, good writeability, and excellent mechanical durability. and anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0085] The invention is further explained below with illustrative non-limiting examples.

[0086] experiment method

[0087] Use the following test method.

[0088] Marker dehumidification : Mark the dry erase surface with 14 different markers including 7 dry erase marker brands. These dry erase markers are: AVERY TM MARKS-A-LOT TM (Avery-Dennison, Pasadena, Cal.), BEIFA TM Private label markers (Beifa, Tokyo, Japan), BICTM dry erase markers (BIC Corporation, Milford, Conn., Connecticut), DIXON TM Dry erase markers (Dixon Ticonderoga Co., Heathrow, Fla., Heathrow, Fla.), EXPO TM Bold (Sanford Corp., Bellwood, IL), EXPO TM Low Odor (Sanford Corp.) and QUARTET TM Marker (Acco, Inc, Lincolnshire, IL), Lincolnshire, Illinois. All markers have chisel-shaped sharp points. Choose two color markers from each brand, one is black and the other is red, green or blue. A typical dry erase sample is about the size of a sheet of paper. For each marker brand, reserve a horizontal space ...

example 1

[0104] Example 1-906 hard coating with 0.075% HFPO-UA : The synthesis of HFPO-UA is described in US Patent No. 7,173,778. Dilute HFPO-UA to 25% solids in MEK. A solution of HFPO-UA in MEK was added to the solution of the 906 hard coating to produce a final concentration of 0.075% HFPO-UA solids based on the solids of the 906 hard coating. The solution was then diluted to 25% solids with ethyl acetate. The formulation was coated on a 9in (23cm) wide continuous coater, which included stations for coating, drying, UV curing and coating film winding. The coating formulation was applied to a 3 mil (76 microns) thick white polyester film through a coating die. After coating, the film was passed through a 30ft (9.1m) long blast oven and dried at 130°F (54°C). Then let the film pass through a nitrogen-purged UV curing chamber with H+ bulbs in the curing chamber. The oxygen concentration in the curing chamber is less than 100 ppm. The line speed on the coater was 50 feet per minut...

example 2

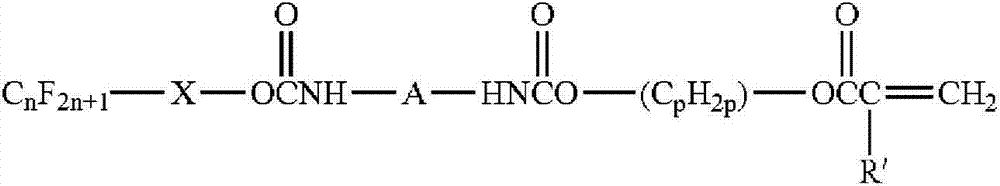

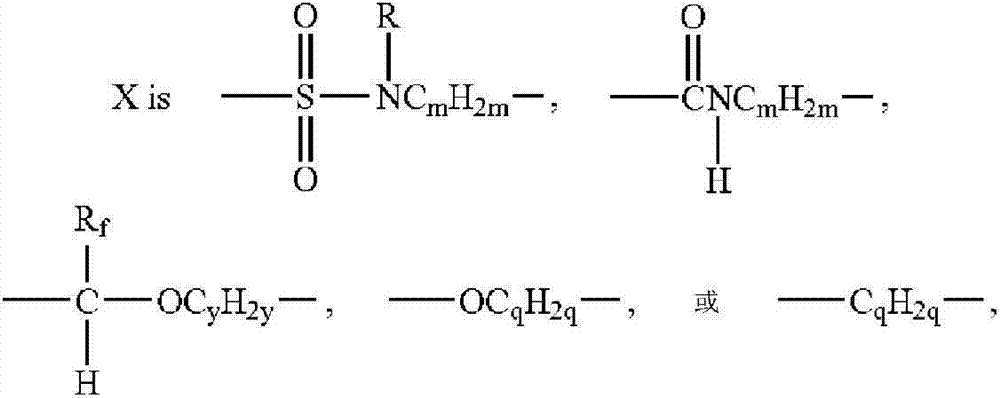

[0105] Example 2-With 10% MeFBSEA(C 4 F 9 SO 2 NMeC 2 H 4 OC(O)CH=CH 2 )of 906 hard coating : MeFBSEA was synthesized according to the procedure described in PCT Application No. WO200130873 (Savu et al.). MeFBSEA was added to the 906 hard coating at a value of 10% based on solids. After mixing, the solution was diluted to 30% solids with MEK. The solution was coated on a 2 mil (50 micron) transparent polyester film with a Mayer rod No. 6. The coated film was dried at 100°C for one minute. Let the film with the dry coating pass through a nitrogen-purged UV curing chamber with an H bulb in the curing chamber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com