Impact tool

A technology of impact tools and anvils, which is applied in the field of impact tools, can solve problems such as enlarged impact mechanism parts, hinder miniaturization, and increase costs, and achieve the effects of maintaining miniaturization, good operability, and a small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described below based on the drawings.

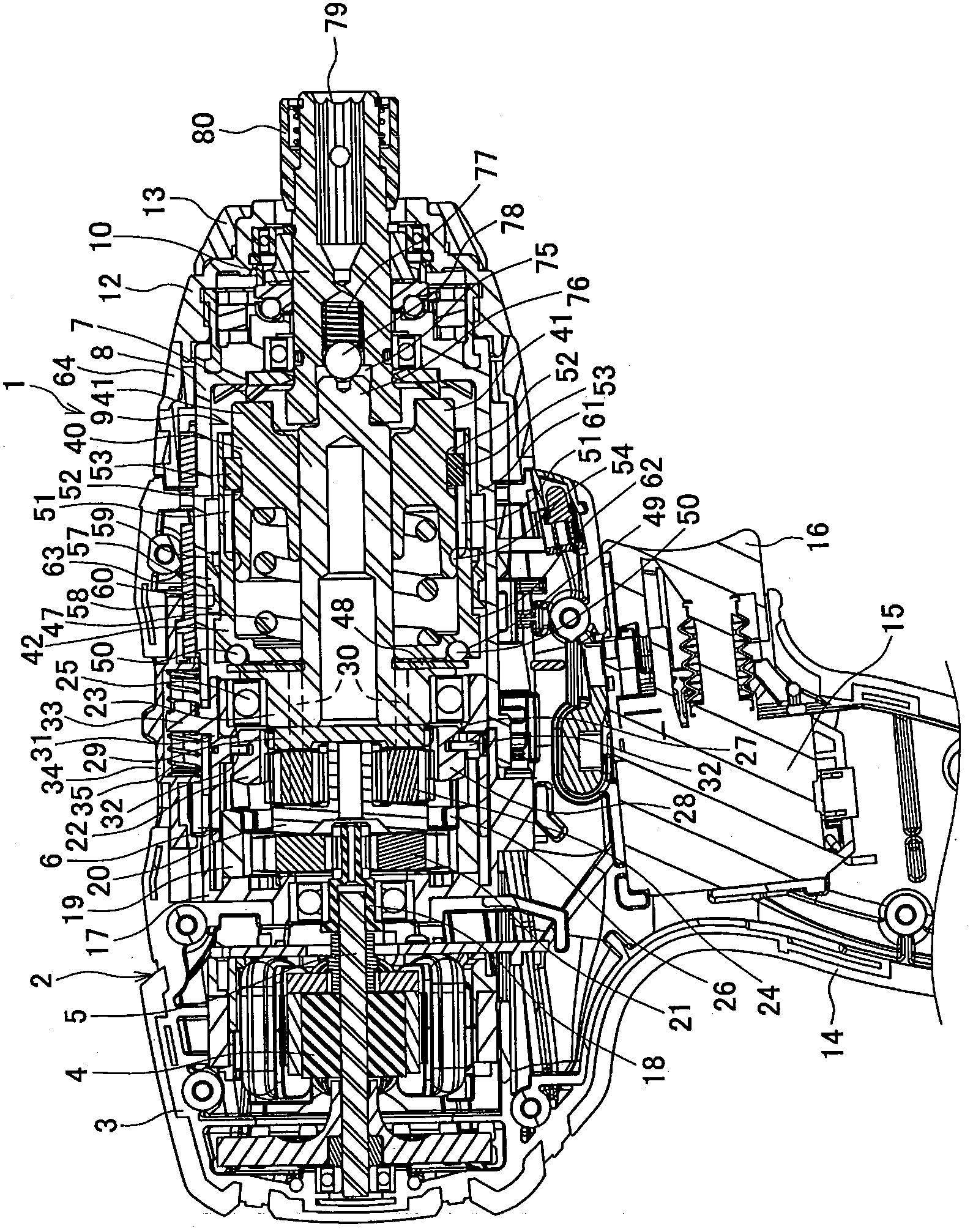

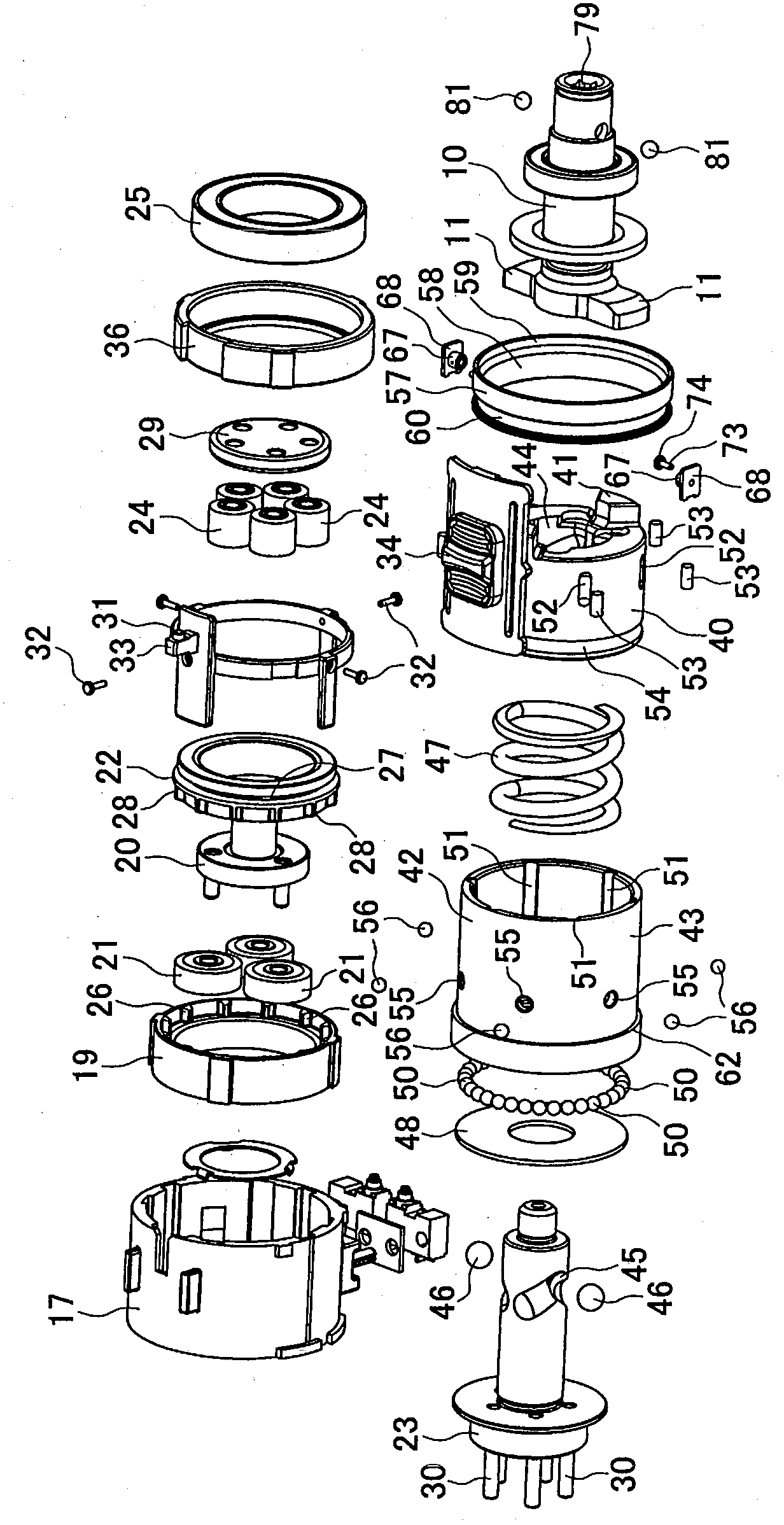

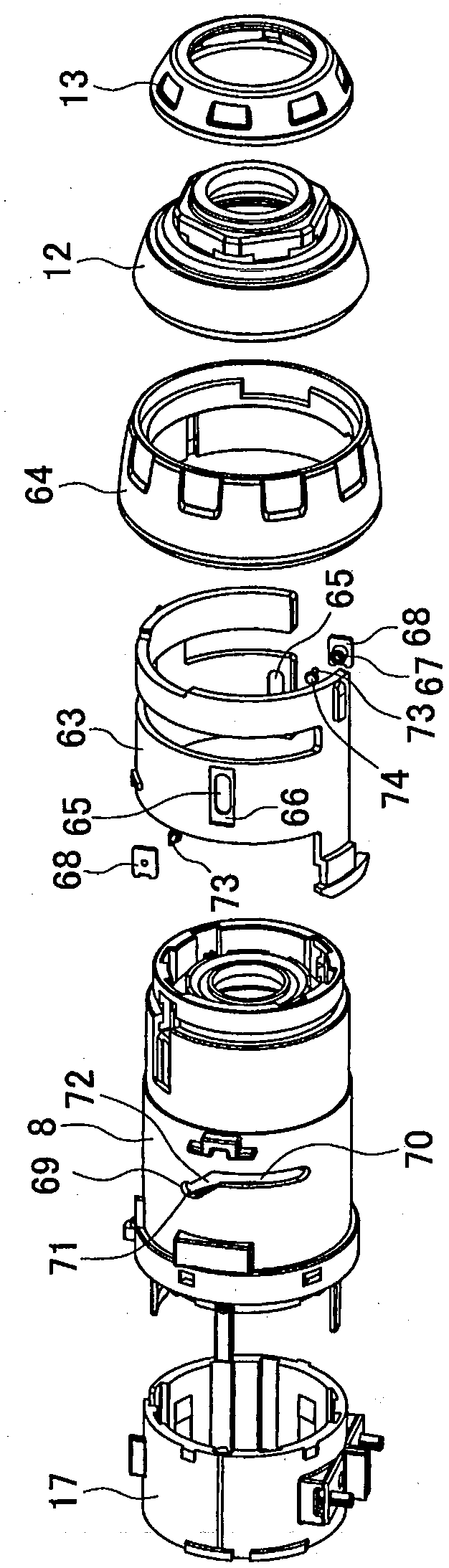

[0020] figure 1 shows an impact screwdriver 1 as an example of an impact tool, figure 2 A part of the internal mechanism of the impact screwdriver 1 is shown. The impact screwdriver 1 has a main body case 2 formed by assembling left and right half shells 3, 3, and can be viewed from the rear (with figure 1 Starting from the right side as the front), a motor 4 , a planetary gear reduction mechanism 6 , and a main shaft 7 are respectively housed in the main body casing 2 . In addition, a cylindrical inner case 8 accommodating the main shaft 7 and the impact mechanism 9 is attached to the front portion of the main body case 2 , and an anvil 10 arranged coaxially in front of the main shaft 7 is rotatably supported by the inner case 8 . and the front housing 12 fixed to the front end of the inner housing 8, and the anvil 10 protrudes forward. 13 is a rubber ring-shaped damper fitted to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com