Embedding piece tooling

A technology of tooling and inserts, applied in the direction of coating, etc., can solve the problems of affecting coaxiality, low efficiency, nut leakage and other problems, and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

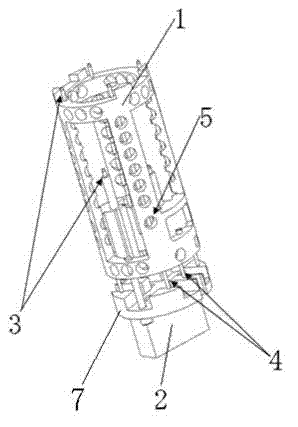

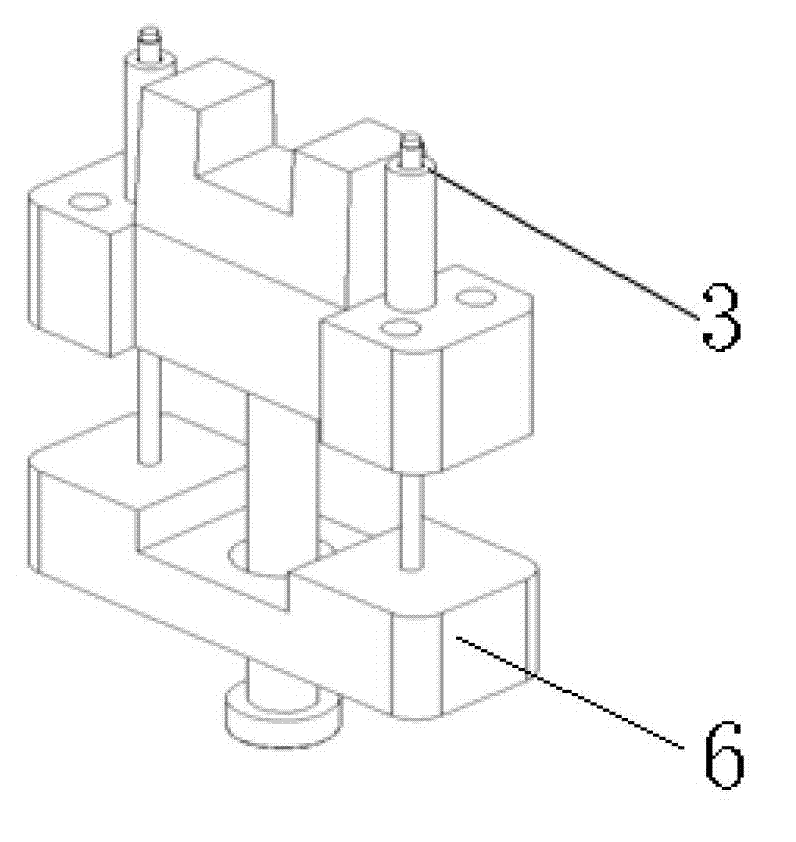

[0020] Such as Figure 1~Figure 2 As shown, an insert tooling includes an outer jig body 1, a jig base 2, a nut 3, a sleeve 4, a material stealing hole 5, and an inner jig 6. The upper part of the jig base 2 is a disc 7. The main body of the external fixture 1 is installed on the disk 7, and several cylinders 4 are installed vertically along the outer circle above the disk 7. The top of the cylinder 4 passes through the outer wall of the main body 1 of the external fixture, and the center of the disk 7 An inner jig 6 is installed, and an installation position is arranged on the inner jig 6 .

[0021] The outer fixture main body 1 is installed on the disc 7 through bolts.

[0022] The main body 1 of the external fixture is provided with a number of stealing holes 5 .

[0023] The nut 3 is installed on the top of the described division tube 4 .

[0024] A nut 3 is housed in the mounting position above the internal fixture 6 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap