A rear seat wing assembly mounted on a molded body

A technology of flanks and components, applied in the direction of vehicle components, superstructure, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

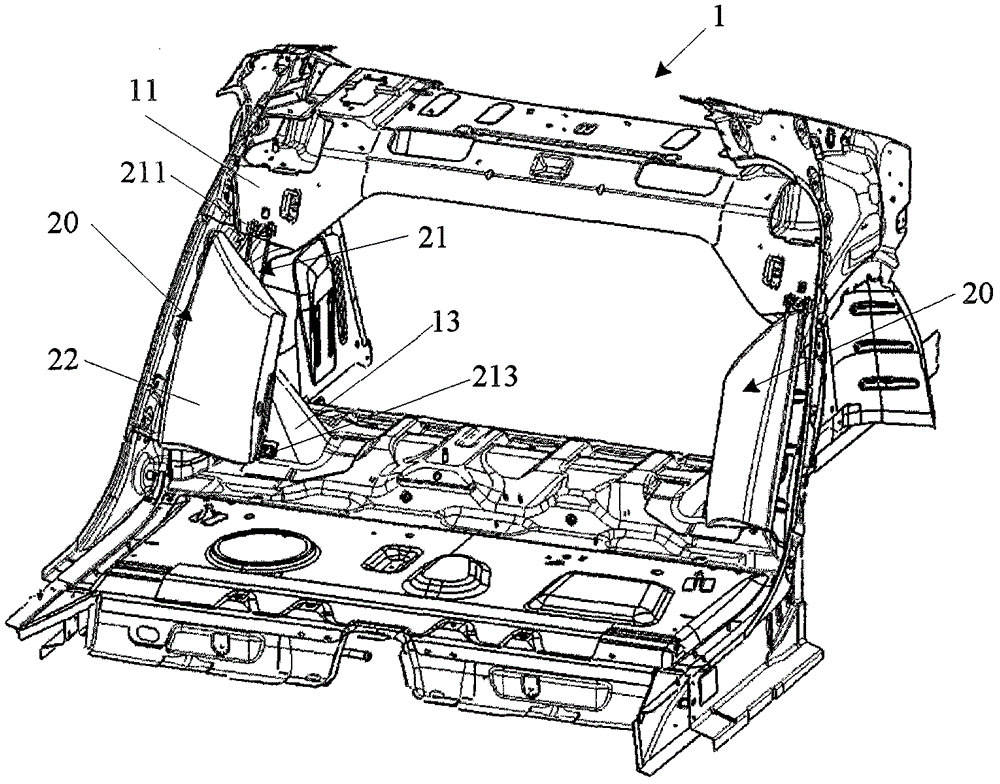

[0019] Such as figure 1 As shown, side bolsters 20 are respectively fixedly arranged on the vehicle body moldings 1 at positions near the doors of the rear seats of the vehicle. The wing assemblies 20 are secured to the body moldings independently of the backs and seats of the rear seats. Here, the vehicle body molding includes a rear floor, a rear wheel house, a connecting member 13 connected between the rear floor and the rear wheel house, and a rear seat upper cross member.

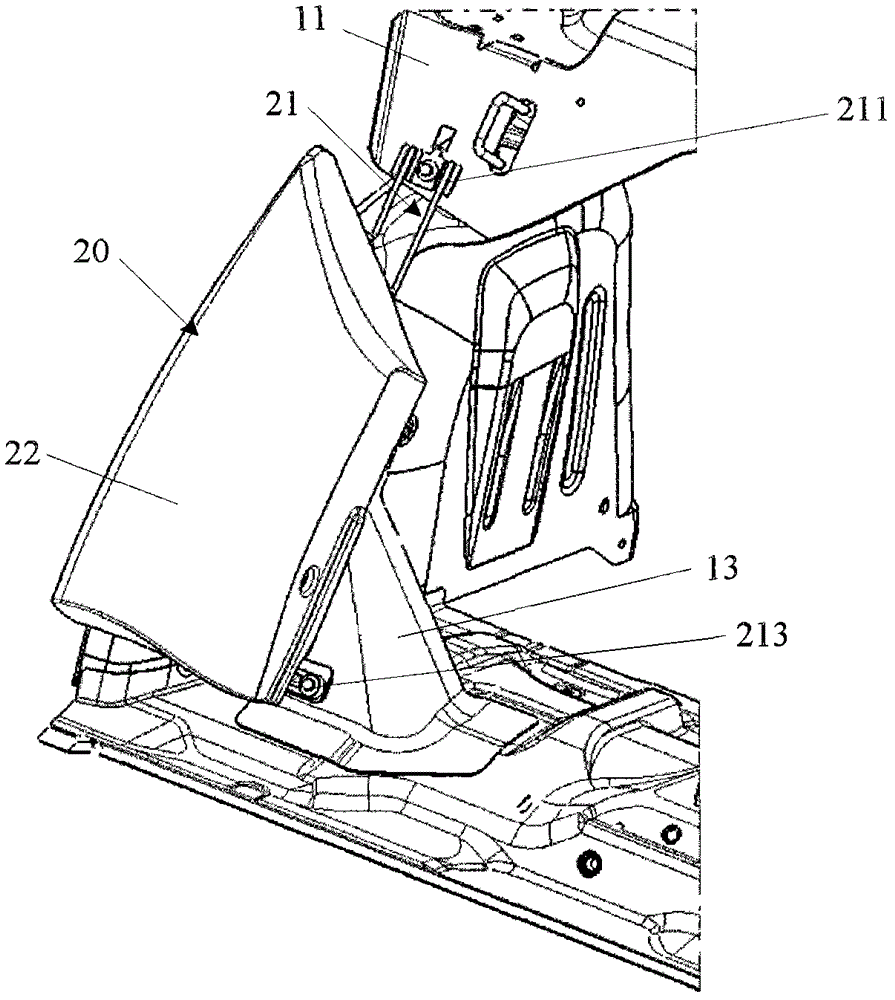

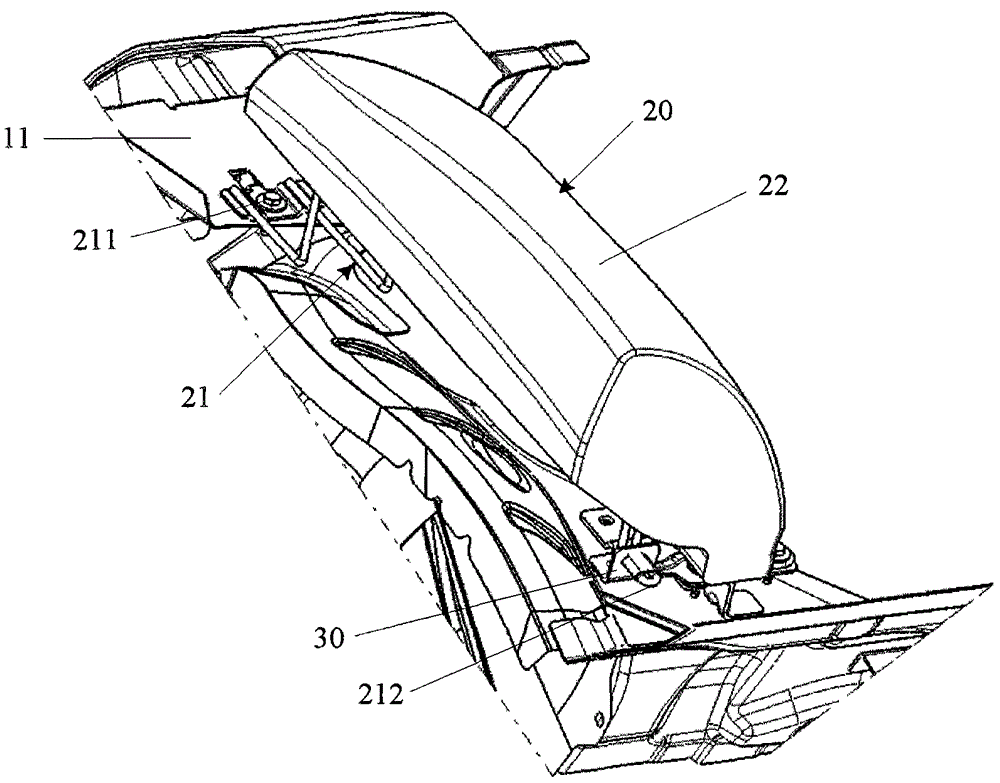

[0020] exist figure 2 and 3 An enlarged view of a wing assembly 20 on one side is shown in , wherein the wing assembly 20 includes fixing brackets 21 extending from the top and bottom sides of the wing body 22 so as to be fixedly mounted on the vehicle body molding 1 . The fixing bracket 21 is integrally formed with the wing body 20 . The fixing bracket 21 is preferably in the form of a plurality of rigid rod brackets and includes an upper joint end 211, a first lower joint end 212 and a second lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com