Lead connector

A wire connector, conductive connection technology, applied in the direction of multi-conductor connector, conductive connection, connection, etc., can solve the problems of complicated installation and production connection, complex connector or terminal structure, and unsatisfactory wiring effect, etc. To achieve the effect of simplifying wiring steps and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

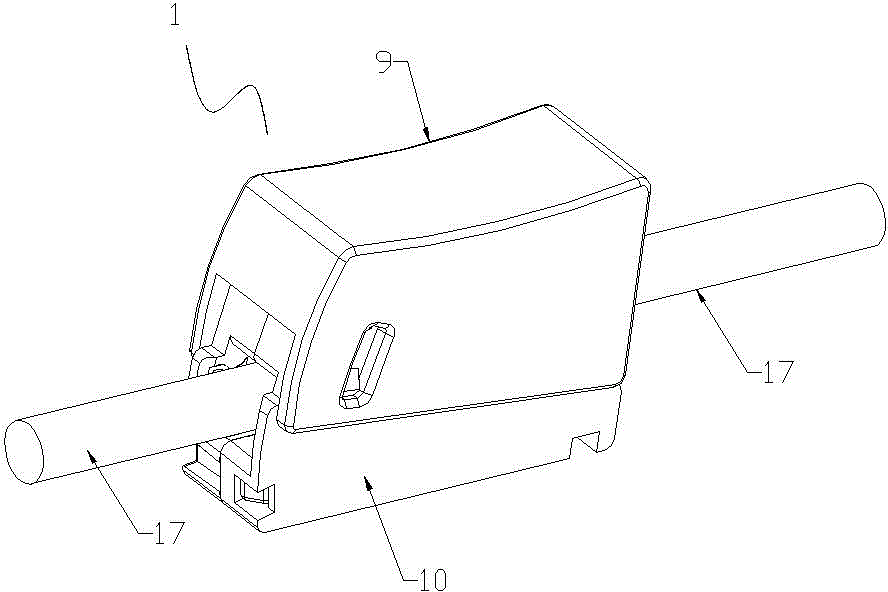

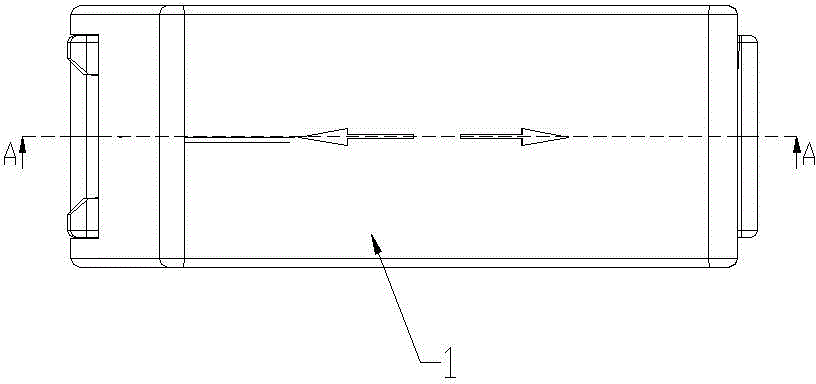

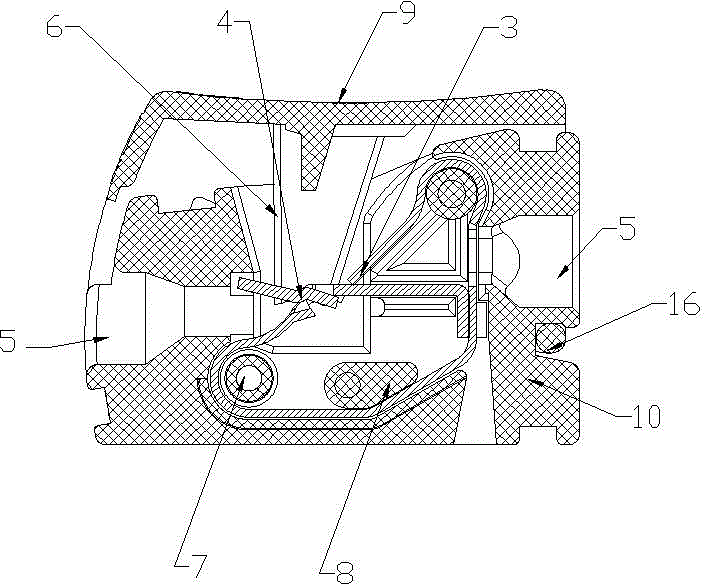

[0026] A wire connector described in Embodiment 1 of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, it includes a housing 1 and a conductive connecting body placed in the housing. The conductive connecting body is composed of a cage-shaped elastic frame and a conductive piece fixed on the cage-shaped elastic frame. One end of the conductive sheet is fixed on the cage-shaped elastic frame, and the other end passes through the incision; the cage-shaped elastic frame is divided into two ends by the incision and corresponding to the conductive sheet, and the housing is provided with a channel corresponding to each port of the cage-shaped elastic frame. hole. Utilizing the design of the cutout and the conductive sheet, the cage-shaped elastic frame can connect flexible wires and hard wires at the same time. When the wire 17 is inserted into the connector for wiring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com