Quick LED strip connecting equipment

A quick-connect, LED substrate technology, applied in lighting and heating equipment, lighting devices, light sources, etc., can solve the problems of cumbersome wiring time and procedures, many LED strip steps, troublesome wiring, etc., to simplify wiring steps and operability, Improved efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

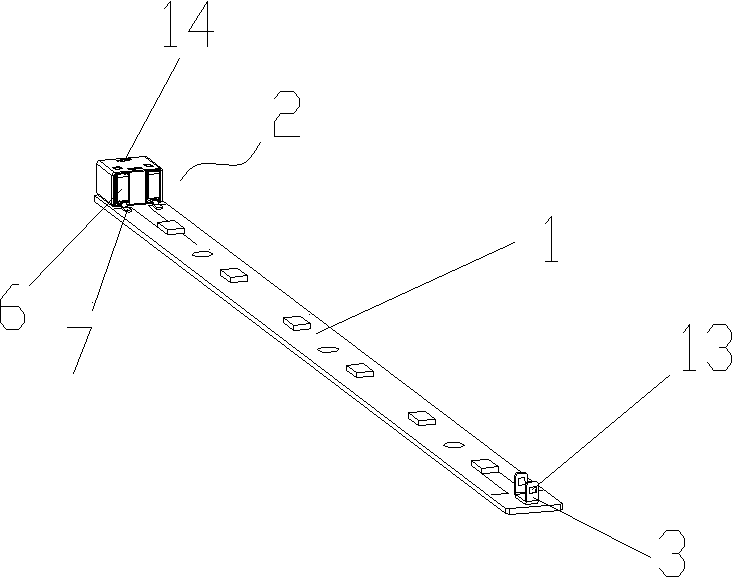

[0025] A LED bar quick connection device described in Embodiment 1 of the present invention, such as figure 1 , figure 2 , image 3 As shown, it includes the LED substrate and the LED strip 1 arranged on the LED substrate. The two ends of the LED strip are separately provided with connecting terminals 2 that can communicate with external wires. The buckle mouth of the connector is matched with the buckle; the buckle is a U-shaped lug 3, and the U-shaped lug is provided with an elastic chamfered bayonet 13; The slot is provided with a notch matched with the chamfered bayonet. The connection terminal is composed of an integrated shell 10 and two conductive sheets 6, the two conductive sheets correspond to the sockets and are fixedly connected with the conductive ends of the wires, two through slots are arranged at the front and rear positions in the casing, one side of the conductive sheet is closed, and one The side is an open structure.

[0026] The connecting terminal is...

Embodiment 2

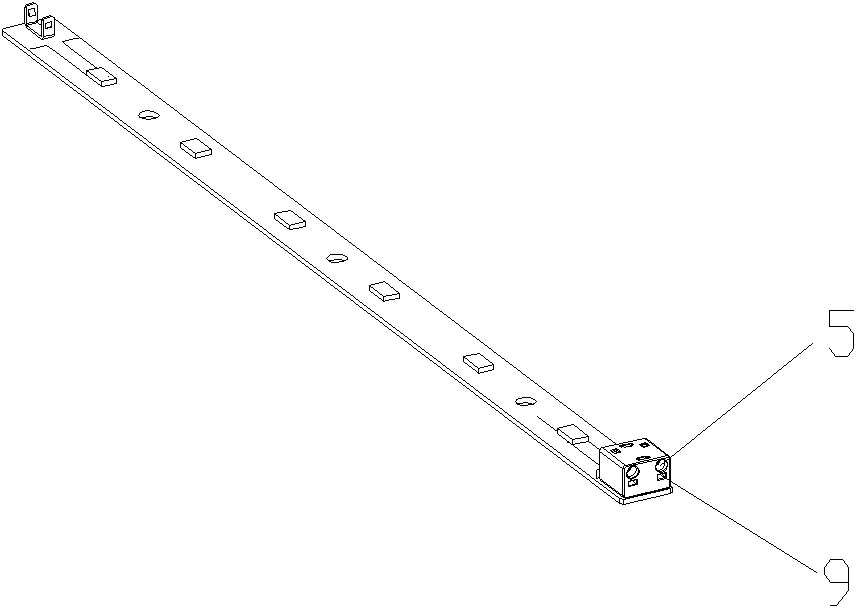

[0029] This embodiment 2 is to change on the basis of embodiment 1, specifically to change the conductive sheet, as follows: Figure 4 , Figure 5 As shown, both sides of the conductive sheet 6 of the present invention are open structures.

Embodiment 3

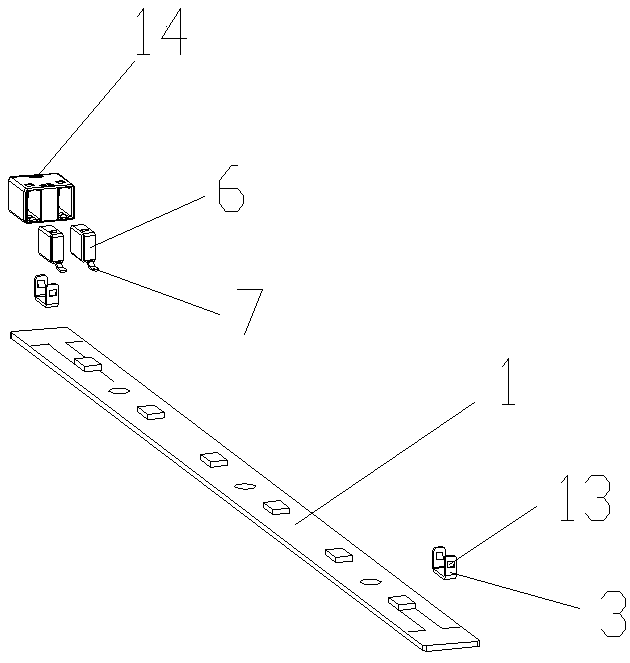

[0031] A LED bar quick connection device described in Embodiment 3, such as Figure 6 , Figure 7 , Figure 8 As shown, it includes the LED substrate and the LED strip 1 arranged on the LED substrate. The two ends of the LED strip are separately provided with connecting terminals 2 that can communicate with external wires. The connector fits the buckle mouth of the buckle. The connecting terminal is composed of two independent left casings 11, right casing 12, and conductive sheets placed in the left casing and the right casing. There is a through groove; the buckle is composed of a U-shaped lug 3 and two symmetrical L-shaped lugs 4, the U-shaped lug corresponds to the inner through groove of the left and right housings, and the two symmetrical L-shaped lugs The protruding pieces correspond to the through grooves on the outside of the left and right casings respectively, and both sides of the conductive sheet are open structures. Both the U-shaped lug and the two symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com