Bridge crane

一种桥式起重机、主桁梁的技术,应用在行走的桥式起重机、起重机、小车的起重机等方向,能够解决危险、绳索松弛度危险、耗费卷扬机构时间等问题,达到减小尺寸、提升工作精确的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

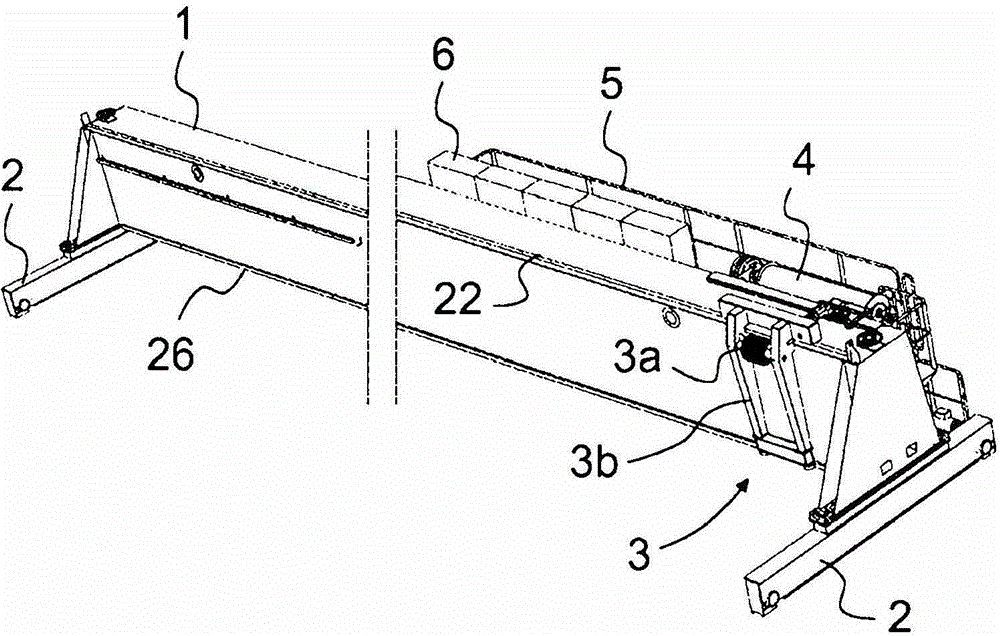

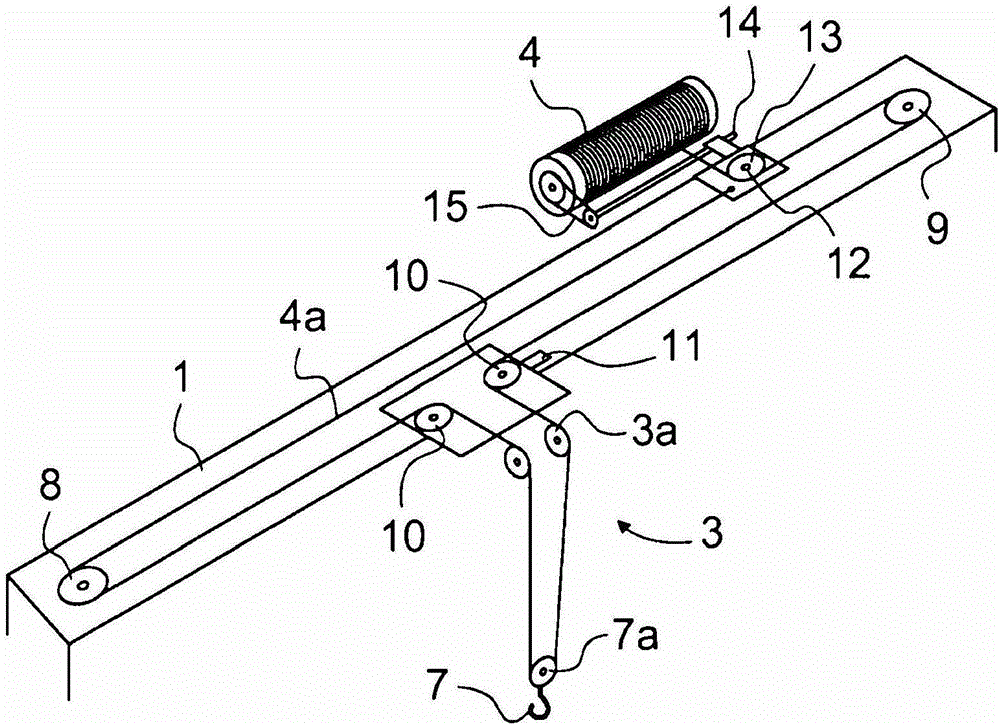

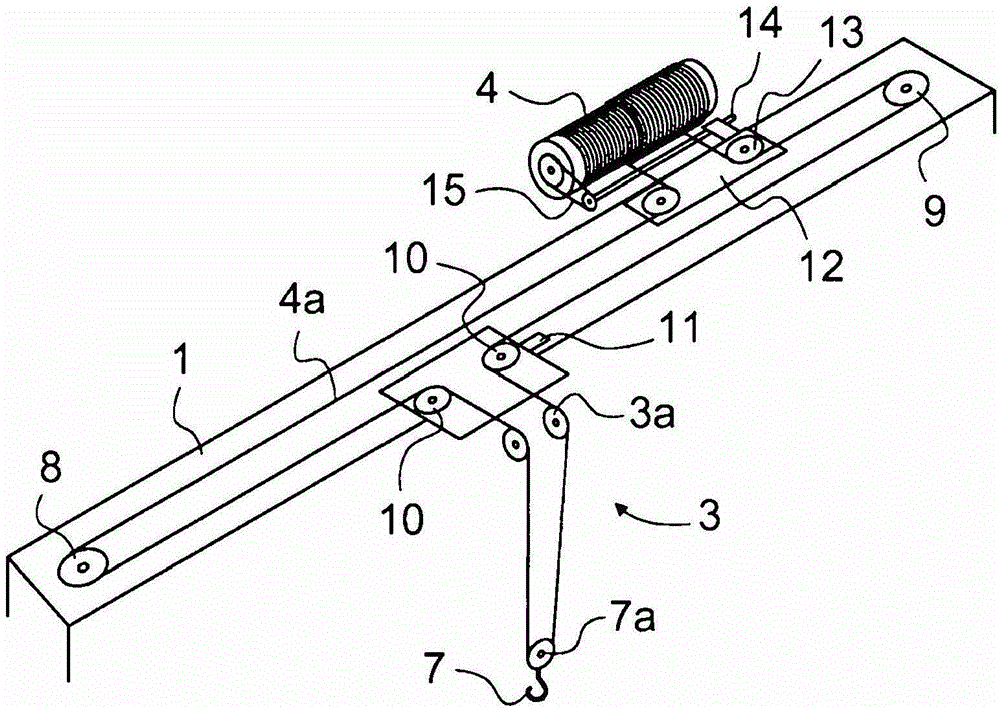

[0024] figure 1 A slanted top view of a simplified and segmented bridge crane according to the present invention is shown, without hoisting ropes, hooks and some other components belonging to the solution, which will be described below. The bridge crane is also called the torsion bridge crane, and it includes a main girder 1, at both ends of the main girder 1, there are end slides 2, which are provided with at least rails Wheel and traveling mechanism. The hoisting tackle 3 is assembled to be combined with the first side of the main girder, and the trolley travels in a lateral direction relative to the traveling direction of the main girder 1 on the first side of the main girder. The hoisting trolley 3 includes a pulley 3a for hoisting the rope and a frame member provided with legs 3b. The frame member abuts on the guide rails 22 and 26 along the longitudinal direction of the main girder, which is at the top of the main girder 1. And on the bottom edge of the first side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com