A bottom stirring tank

The invention is a technology of stirring tank at the bottom of the kettle and the bottom of the kettle, which is applied to the field of stirring tank at the bottom of the kettle, which can solve the problems of lip seal and throttling bushing damage, sealing leakage, etc., to achieve good sealing performance, reduce eccentric wear damage, and prevent sealing leakage accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

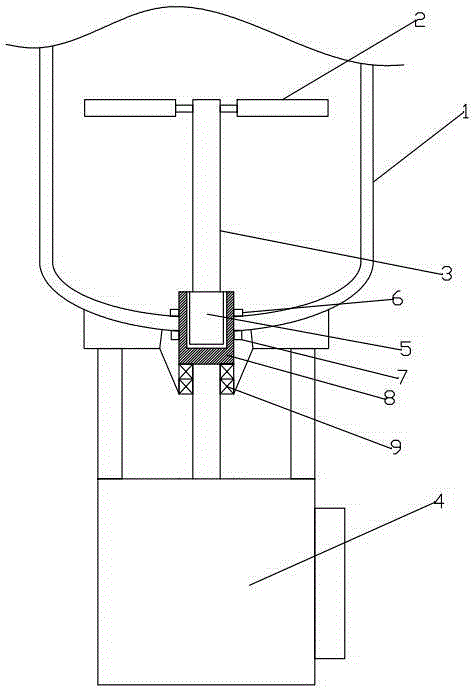

[0008] In order to gain an in-depth understanding of the structure of a stirred tank at the bottom of the kettle, combined with figure 1 described as follows:

[0009] A stirring tank at the bottom of the kettle includes a stirring device 2 and a stirring shaft 3 at the bottom of the reaction kettle 1, and a transmission device 4 is fixed on the bottom of the reaction kettle 1, and a transition is provided between the lower end of the stirring shaft 3 and the transmission device 4 Shaft 5, the transmission device 4 is fixed on the bottom of the kettle through the equipment installation flange at the bottom of the reactor 1, the stirring shaft 3 is connected with the transmission device 4 through the transition shaft 5, and the transition shaft 5 has a sealing ring 6 and joints The flow device 7, the transmission device 4 and the bottom of the reaction kettle 1 are provided with a cartridge combined mechanical seal 8, the lower part of which is designed with a self-aligning bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com