Printed circuit board jet printing motion scanning method

A technology of printed circuit board and scanning method, applied in the direction of copying/marking method, printing, etc., can solve the problems of pattern disconnection, nozzle blockage, pattern can not have disconnection, etc., to achieve consistent printing quality and avoid disconnection problems , cost and efficiency guarantee effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

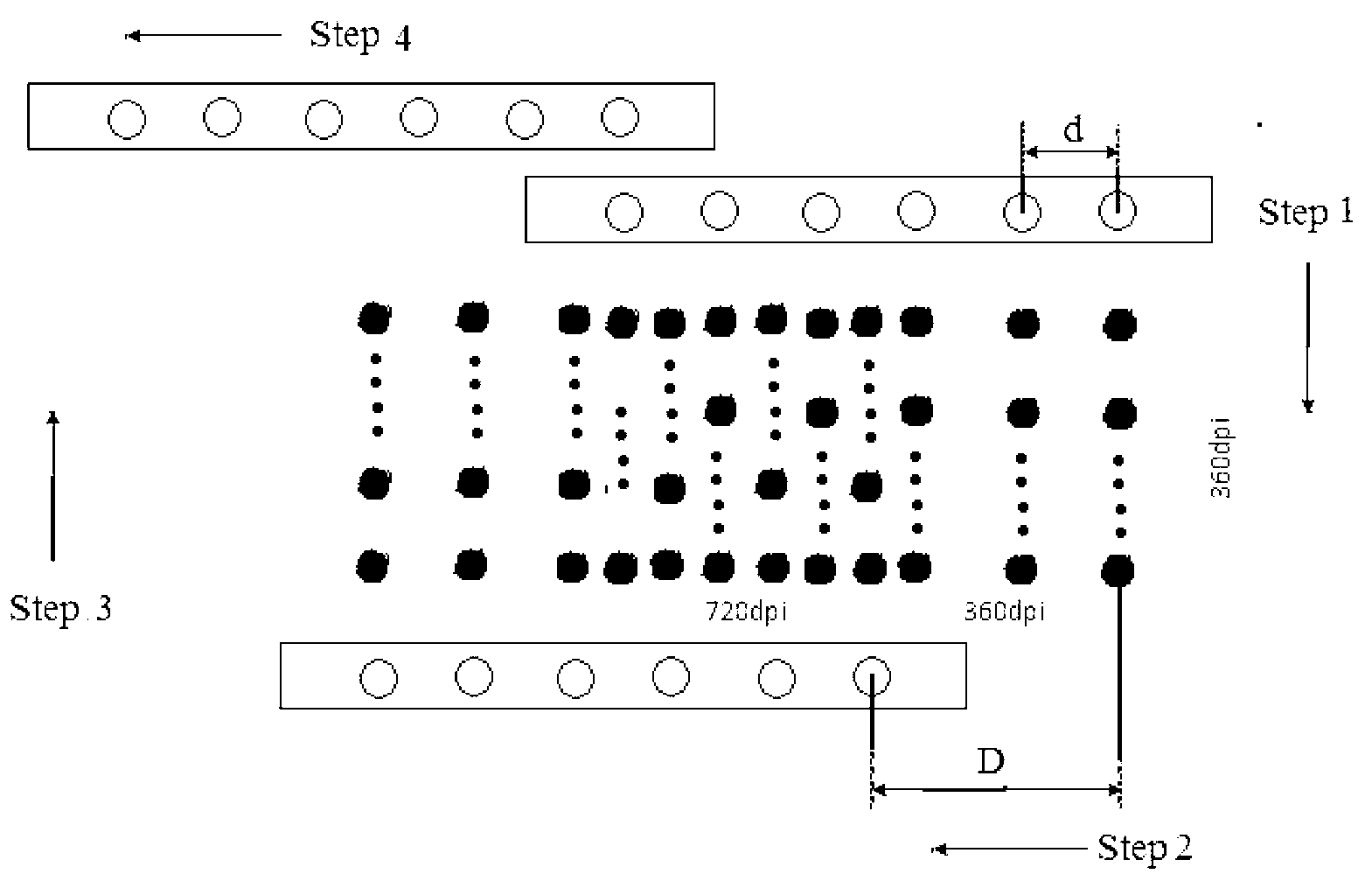

[0022] see figure 1 , the nozzles are arranged with 6 nozzles in 360dpi (that is, there are 360 nozzles in 1 inch length) physical resolution, that is, the nozzle hole distance d is 1 / (360-1) inches.

[0023] The trajectory of the nozzle movement is shown by the arrow line:

[0024] Step1: Print one inch along the positive direction of scanning, and scan out 360×6 matrix points;

[0025] Step2: Move along the stepping direction D=(6-1)×d / 2 or 2.5d;

[0026] Step3: Print one inch along the opposite direction of scanning, and scan through dot insertion, the resolution of the stepping direction of the cross section reaches 720dpi;

[0027] Step4: Move the nozzle along the stepping direction D;

[0028] Repeat the above process, that is, the uniform stepping of the insertion point and the bidirectional scanning mode, to complete the printing process of the printed circuit board.

Embodiment 2

[0030] The same nozzle, the difference is that each step distance D=(6-1)×d / 3, and finally realized the step direction resolution of 1080dpi.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com