Ceramic plate group, ceramic valve core utilizing same and water heater valve utilizing same

A technology of ceramic valve core and ceramic plate, which is applied to multi-way valve, valve device, engine components, etc., can solve the problem of linear flow control, unreasonable structure design of ceramic plate group, unreasonable structure design of ceramic plate group, incapable of moving plate Rotary flow linear control and other issues, to avoid the effect of water temperature fluctuating cold and hot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

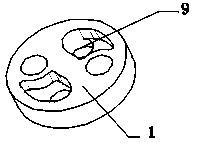

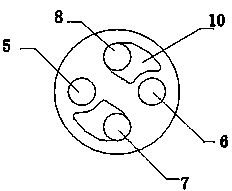

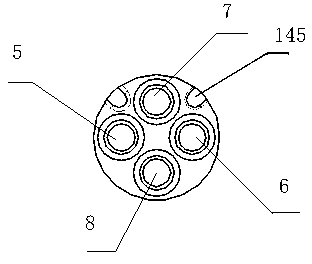

[0061] In this embodiment, the ceramic stator 1 (see figure 1 ) is a cylinder, and the sink platform 9 in the diversion area of the stator (see figure 2 ) is two, and the cross-sections of the sinking platform 9 in the diversion area of the two stators are respectively the closed curves 10 of the stators formed by the smooth transition connection of the head and tail of several arcs, and the two closed curves 10 of the stators are about their positions The center of the circular surface is distributed symmetrically to the center; the water passing holes are a group of cold and hot water inlet circular through holes 5, 6 and a group of cold and hot water outlet circular holes that are uniformly distributed in the circumferential direction of the circular surface where they are located. Through holes 7, 8, see figure 2 and image 3 , the cold and hot water inlet circular through-holes 5, 6 and the cold and hot water outlet circular through-holes 7, 8 are center-symmetri...

no. 2 example

[0068] In this embodiment, the ceramic stator 1 (see Figure 11 ) not with the ceramic rotor 2 (see Figure 14 ) There are three circular holes distributed in a triangular shape at the matching end (see Figure 13 ), the three round holes distributed in a triangular shape include the cold water delivery through hole 4, the water outlet half through hole 95 at the water heater end, and the water outlet half through hole 94 at the water removal end (see Figure 12 ); Preferably, the cold water delivery through hole 4, the water outlet semi-through hole 95 at the water heater end and the water outlet half through hole 94 at the mixed water end are evenly distributed in a triangular shape on their end faces;

[0069] The sink platform 9 in the diversion area of the ceramic stator (see Figure 12 , Figure 13 ) is three, which are the sinking platform 91 of the cold water diversion area and two sinking platforms of the waist-shaped diversion area symmetrical to the axis of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com