Thin-plate stamping mold with size being greater than closed height of press machine and stamping method

A thin plate stamping and stamping die technology, applied in the thin plate stamping die and stamping field, can solve the problems of large-size thin plate stamping, etc., and achieve the effects of short manufacturing cycle, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiment given in conjunction with accompanying drawing, the present invention is described:

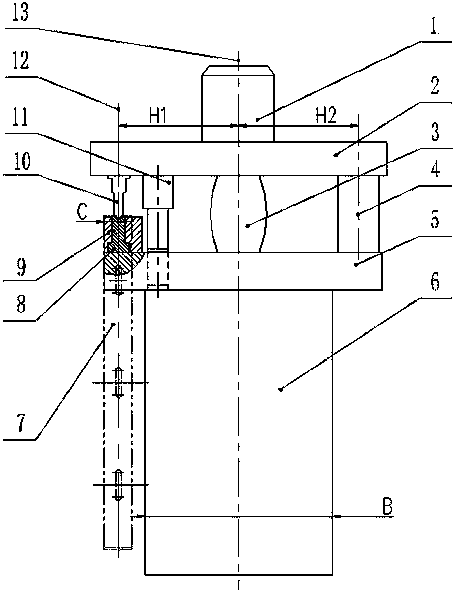

[0019] Such as figure 1 As shown, a thin plate stamping die whose size is larger than the closed height of the press includes a die handle 1, a punch 10, a die 8, an upper die 2, a lower die 5, a positioning plate 9, a guide device 11, a support block 4 and rubber Block 3 etc. The punch 10 and the die 8 are composed of multiple sets, which are fixed on the upper template 2 and the lower template 5 respectively, and deviate from the stamping die center 13; the upper template 2 and the lower template 5 adopt guiding devices 11 for positioning and guiding to ensure the concentricity of the punch and die during stamping; the guide device 11 is composed of a guide sleeve arranged at the bottom of the upper template and a guide column arranged at the upper part of the lower template, and the guide sleeve corresponds to the guide column set up. The size of the lower template 5 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com