Multi-feature compound punching rotary die for tension plate and working method thereof

A rotary mold and multi-feature technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of poor processing accuracy, time-consuming and labor-intensive, etc., and achieve the effect of shortening processing time, reducing labor and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

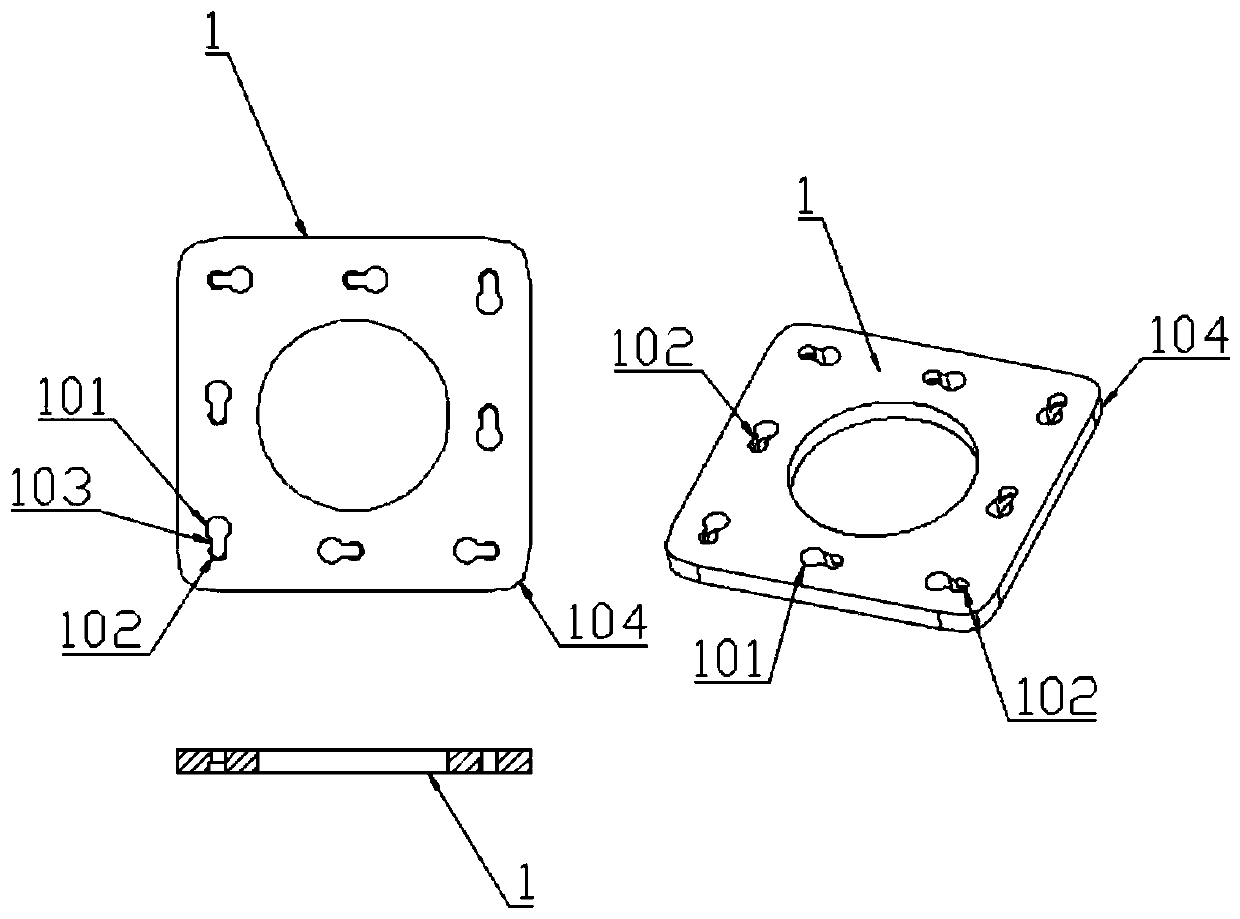

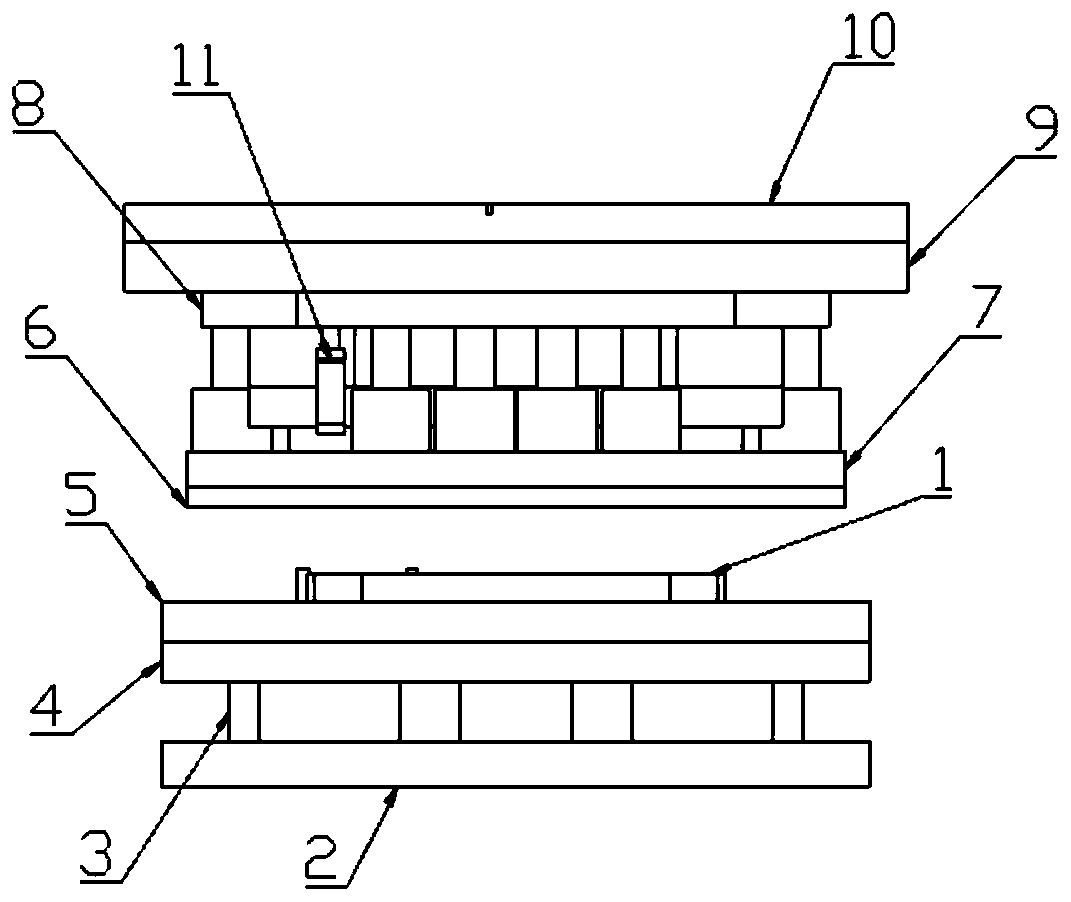

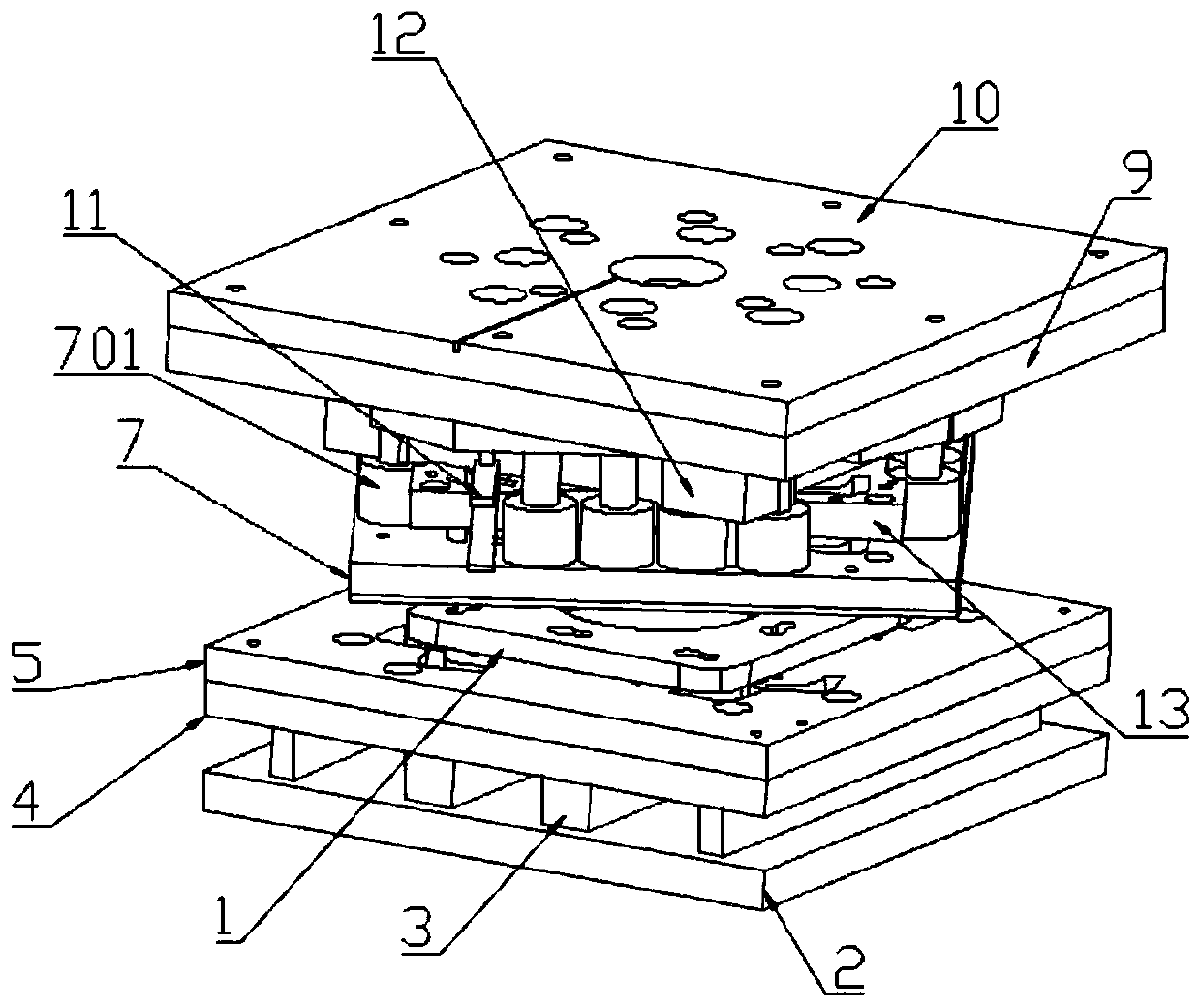

[0053] Such as figure 2 , 5 As shown, a multi-feature composite stamping rotary die for a tension plate includes an upper die assembly and a lower die assembly, and the upper die assembly includes a counterbore punch 1302, a combined punch 1301, and a fillet punch 1303, The counterbore punch 1302 punches each counterbore 102, the combined punch 1301 processes the through hole 101 and the strip groove 103 of the tension plate 1, and the rounded corner punch 1303 cooperates with the lower die assembly to process the tension The rounded corners 104 of the four corners of the plate 1, the counterbore punch 1302 and the combination punch 1301 can shrink into the cavity 902 respectively when rotating, and the position deflection angle of the counterbore punch 1302 and the combination punch 1301 is the same as the rotation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com