A kind of 700mpa hot-rolled trip-assisted dual-phase steel and its preparation method

A dual-phase steel and main body technology, which is applied in the field of hot-rolled advanced high-strength steel for automobiles, can solve problems such as difficult to meet and difficult to form, and achieve the effects of improving safety factor, good economic applicability and application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The second aspect of the present invention provides a method for preparing the above-mentioned 700MPa hot-rolled TRIP-assisted dual-phase steel, the steps comprising:

[0027] S1. Hot metal smelting and casting to obtain a billet meeting the chemical composition requirements, heating the billet to 1150-1250°C under the protection of 99.99% high-purity nitrogen and keeping it warm for 1.5-2.5 hours;

[0028] S2. Controlled hot rolling of the slab after heat preservation, the controlled hot rolling includes 2-3 passes of rough rolling and 3-5 passes of finish rolling, the total reduction of the rough rolling is 82-84%, and the rough rolling After each pass, it enters the coil box for heat preservation treatment. The finish rolling is rolled at a constant speed of 7-8m / s, and the total reduction of finish rolling is 84-85%. steel belt;

[0029] S3. Water-cool the hot-rolled steel strip to 680-700°C at a cooling rate of 60-70°C / s, then air-cool for 20-30s, and then water-c...

Embodiment 1

[0032] This embodiment provides a method for preparing a 700MPa hot-rolled TRIP-assisted dual-phase steel, the steps of which include:

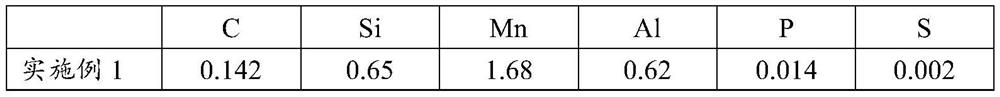

[0033] Heat the billet to 1200°C for 2 hours, and protect it with nitrogen with a purity of 99.99%. The chemical composition of the slab is as follows: by mass percentage, C: 0.142%, Si: 0.65%, Mn: 1.68%, Al: 0.62%, P: 0.014%, S: 0.002%, the rest is Fe and not Avoid impurities.

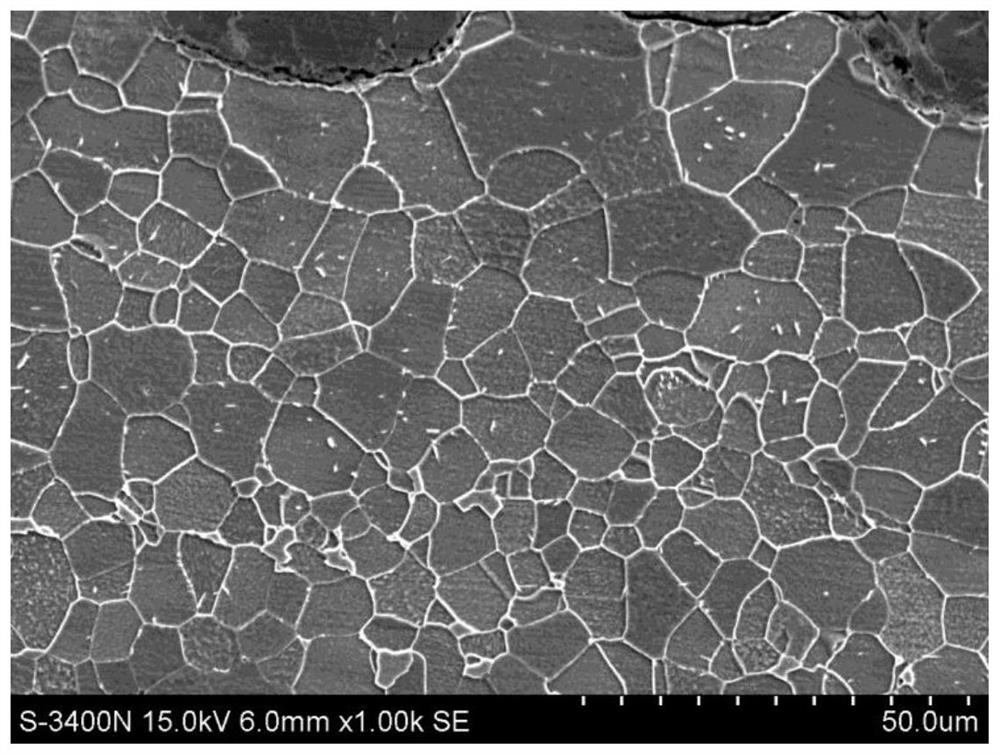

[0034] The hot-rolled slab after heating and heat preservation is started at 1180°C. During the hot-rolling and cooling process, the structure of the hot-rolled steel strip is controlled to be a three-phase structure of ferrite, martensite and a small amount of film-like retained austenite. The controlled hot rolling process is as follows: carry out 3 passes of rough rolling, the total reduction of rough rolling is 83%, and after each pass, enter the coil box for heat preservation treatment; / s speed uniform rolling, the total reduction of finishing rolling is 85%....

Embodiment 2

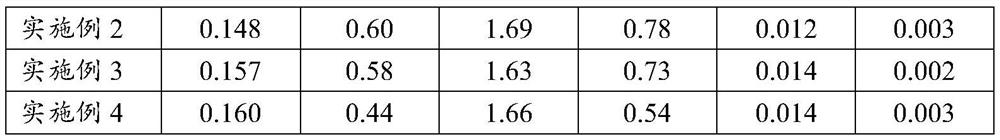

[0037] Example 2, Example 3, and Example 4 all provide a method for preparing a 700MPa hot-rolled TRIP-assisted dual-phase steel. The preparation method is basically the same as that of Example 1, and the difference lies in the chemical composition of the slab and part of the preparation process. Parameters, specifically, the chemical composition of the slab used in Examples 2-4 is shown in Table 1, and the control requirements of the preparation process parameters are shown in Table 2, and the preparation process of the rest of the unmentioned parts is the same as that of Example 1. The microstructure and mechanical properties of the products obtained in Examples 2-4 are shown in Table 2.

[0038] Table 1 each embodiment billet chemical composition mass percent (%)

[0039]

[0040]

[0041] Table 2 Control requirements and mechanical properties of each embodiment (80mm gauge length)

[0042]

[0043] It can be seen from Table 2 that the TRIP-assisted dual-phase ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com