Batch work outputting method and device

A batch job and output method technology, applied in printing devices, printing, etc., can solve the problems of low printing efficiency, achieve the effect of improving printing efficiency and overcoming low printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

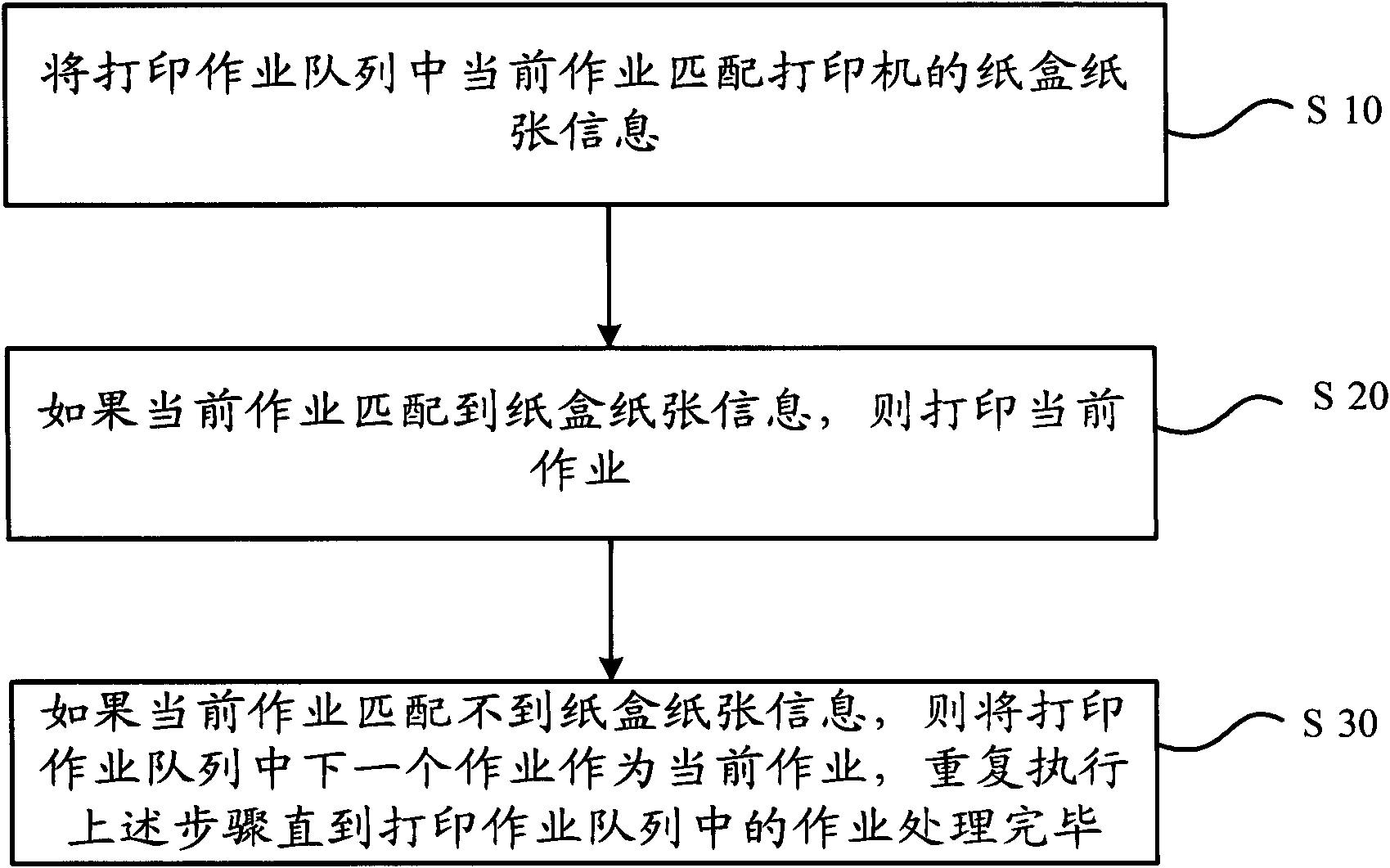

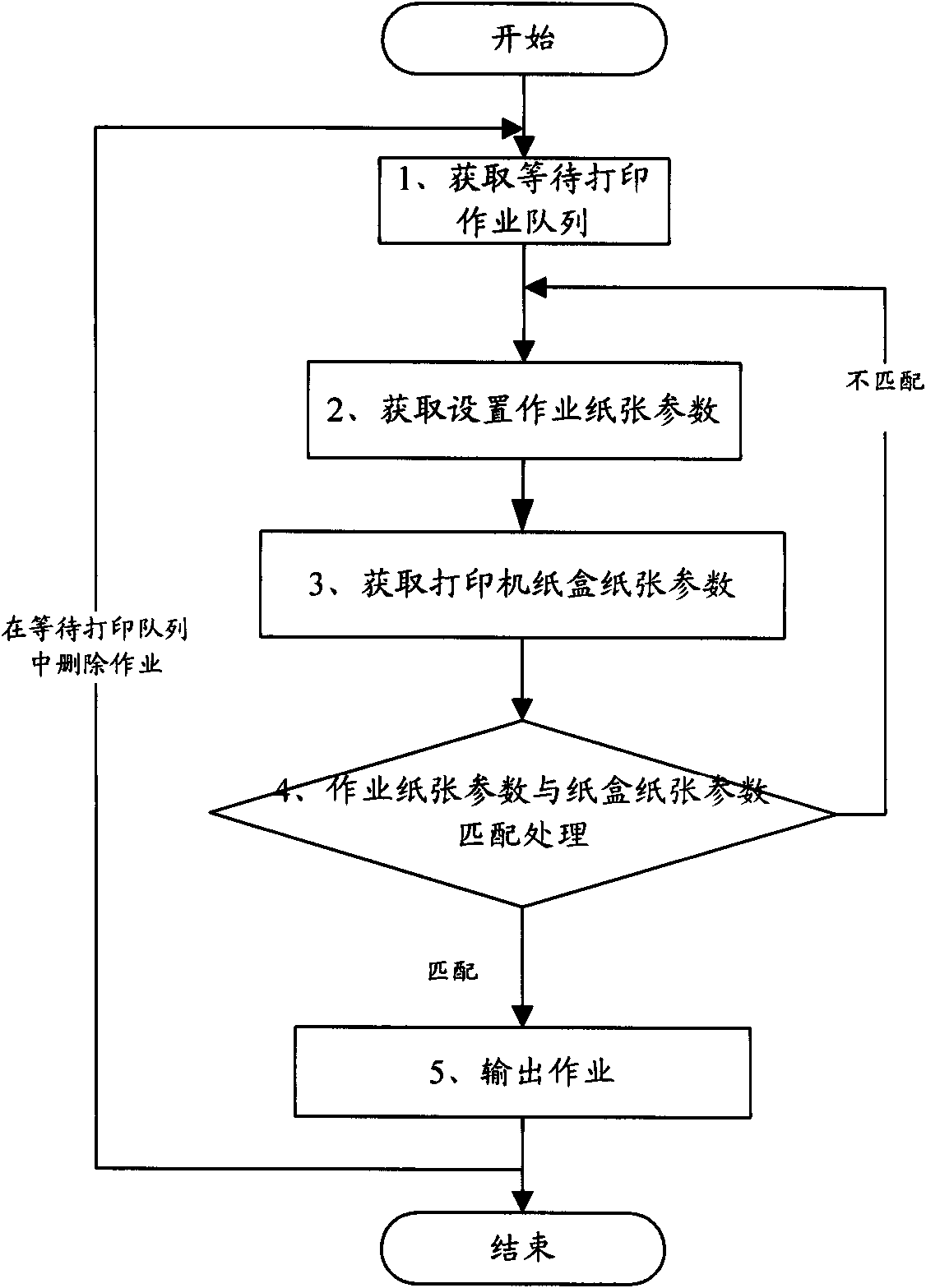

[0013] figure 1 A flowchart showing a batch job output method according to an embodiment of the present invention, including:

[0014] Match the current job in the print job queue to the paper tray information of the printer;

[0015] If the current job matches the tray paper information, print the current job;

[0016] If the current job does not match the paper information of the paper tray, the next job in the print job queue is used as the current job, and the above steps are repeated until the jobs in the print job queue are processed.

[0017] In the prior art, when a job in the print job queue stops due to lack of paper, all jobs following the job must stop, waiting for the user to replenish paper to complete the job. The inventor found that the current job stopped due to lack of paper may be caused by the model mismatch be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com