Manual longitudinal sliding rail for car seat

A technology for longitudinal slide rails and car seats, which is applied in the direction of movable seats, etc., can solve the problems of complex locking structure, reduced flexibility, and high assembly requirements, so as to avoid unilateral force, change the force situation, and simplify the stamping process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

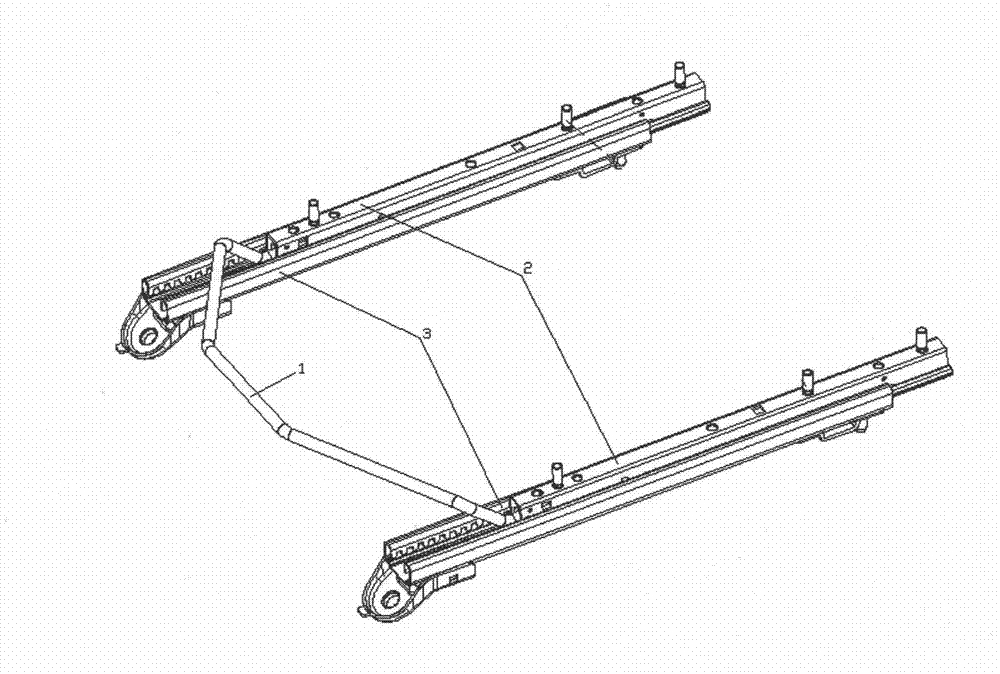

[0024] Such as figure 1 As shown, the present invention provides a manual longitudinal slide rail for a car seat, which includes a handle 1, the middle part of the handle 1 is an operation part that is easy for the operator to hold, and the left and right ends of the handle 1 are connecting parts, and each connecting part is respectively Connected to the respective longitudinal slide mechanism with locking function.

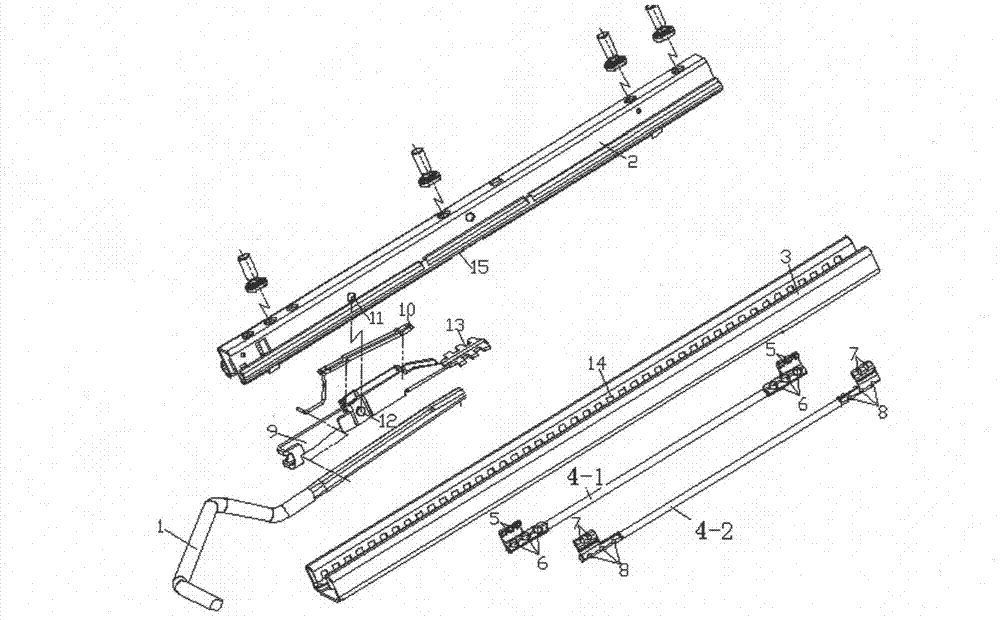

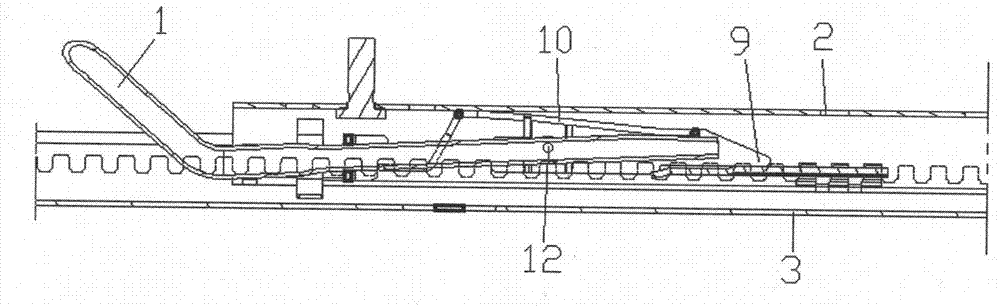

[0025] combine Figure 2 to Figure 4 , the longitudinal sliding rail mechanism includes a lower rail 3 , the upper rail 2 is slidingly fitted on the lower rail 3 and a cavity is formed between the upper rail 2 and the lower rail 3 . Wherein, both sides of the lower rail 3 are turned inward to form an inner hem and a hem cavity, and both sides of the upper rail 2 are turned outward to form an outer hem, and the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com