Deep hole machining auxiliary tools, machining process and air cylinder cover oil drainage hole machining process

A processing technology and cylinder head technology, which is applied in the direction of manufacturing tools, boring/drilling, metal processing equipment, etc., can solve the problems of inability to locate the center position, reduce eccentricity, tool breakage, etc., to reduce eccentricity, reduce Influence of straightness, waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

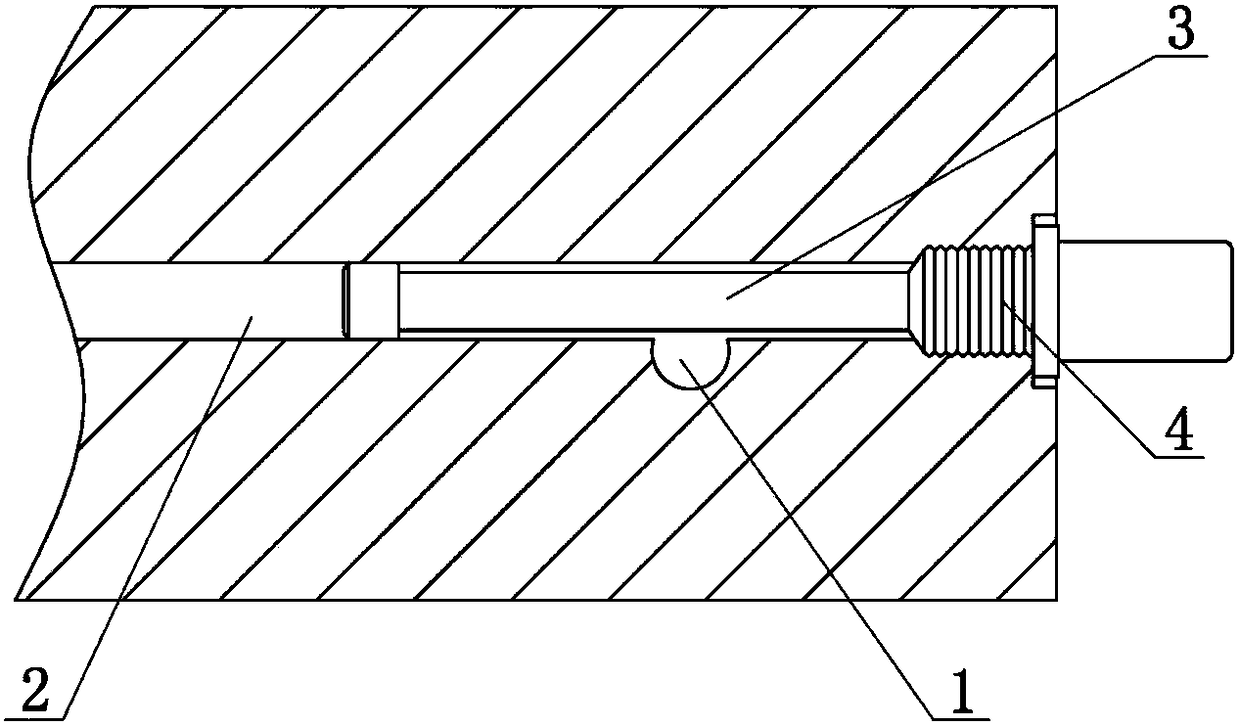

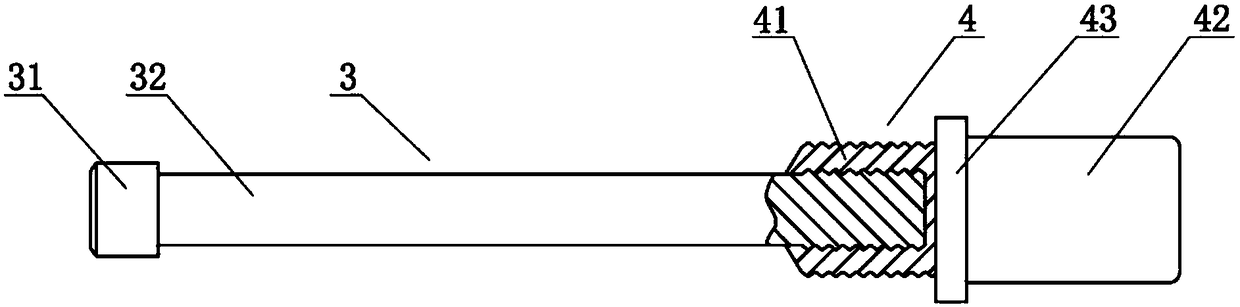

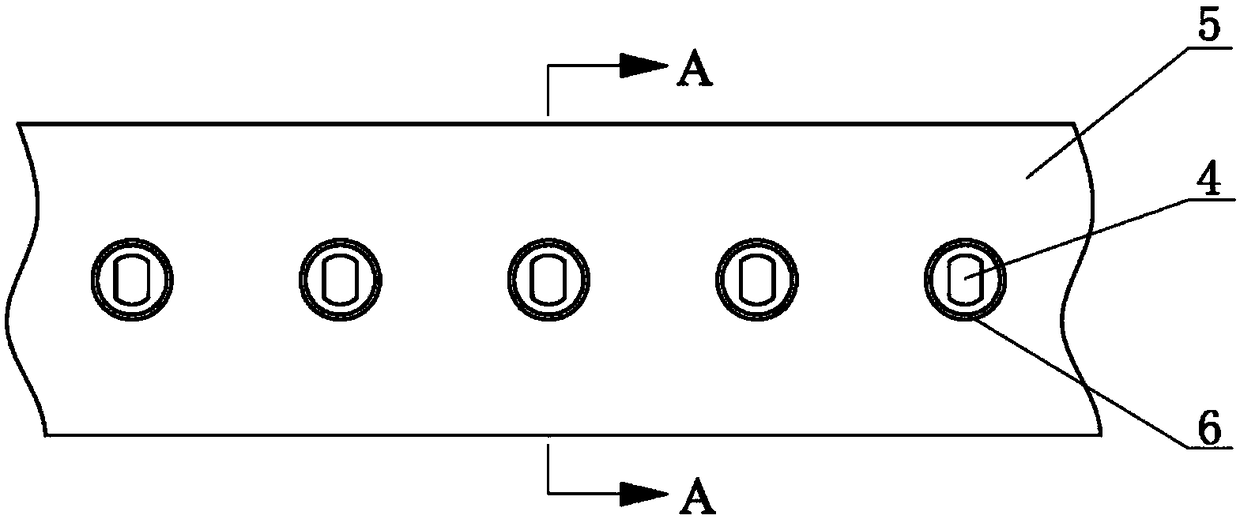

[0036] Concrete embodiment of the present invention is: as figure 1 , figure 2 As shown, a deep hole processing auxiliary tool, a short hole 2 communicating with it is provided at the intersecting position of the deep hole 1, especially when the planes where the central axes of the deep hole 1 and the short hole 2 are located are perpendicular to each other, this auxiliary tool The rod structure configured to be installed in the short hole 2 includes an intrusion portion 3 that is loosely fitted with the short hole 2 and a connecting portion 4 that is pre-tightened and fixed with the short hole 2 .

[0037] Optimally, the protruding part 3 is set as a stepped rod, including a head 31 and a rod 32. The diameter of the head 31 is larger than the diameter of the rod 32, which reduces the inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com