Backlight indicator used by controller and provided with correction film and manufacture method thereof

A manufacturing method and indicator technology, applied in the direction of instruments, electric light sources, refractors, etc., can solve the problems of thin transparent color film, defects, uneven color, etc., and achieve convenient operation, simple manufacture, and overcome high cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

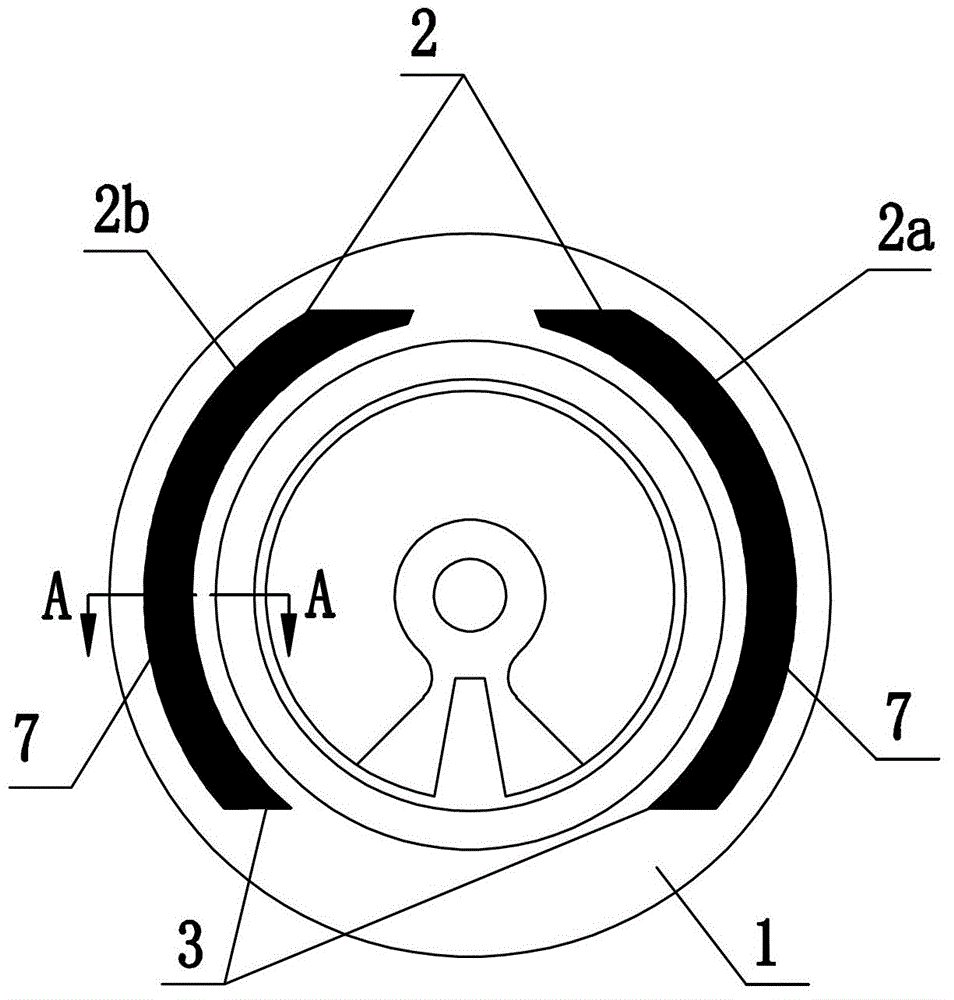

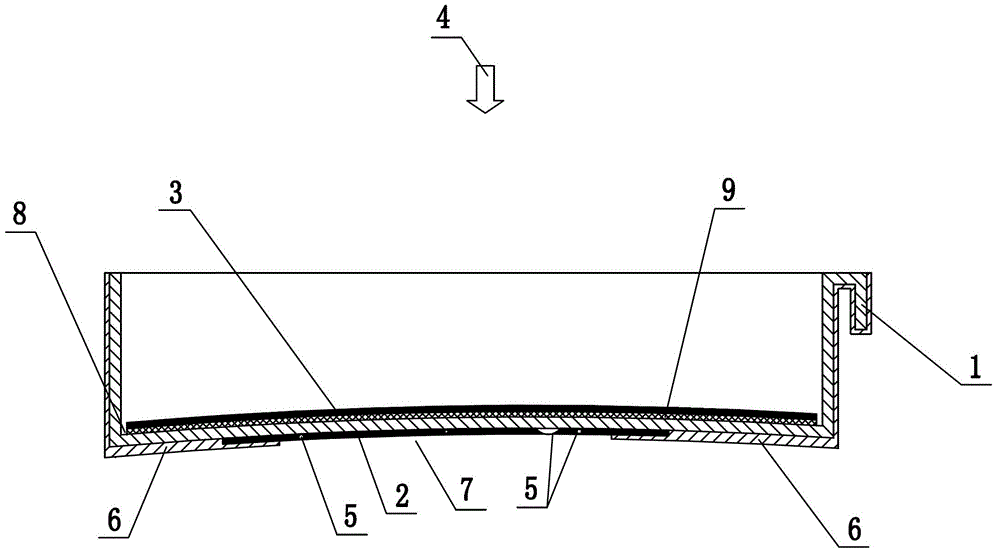

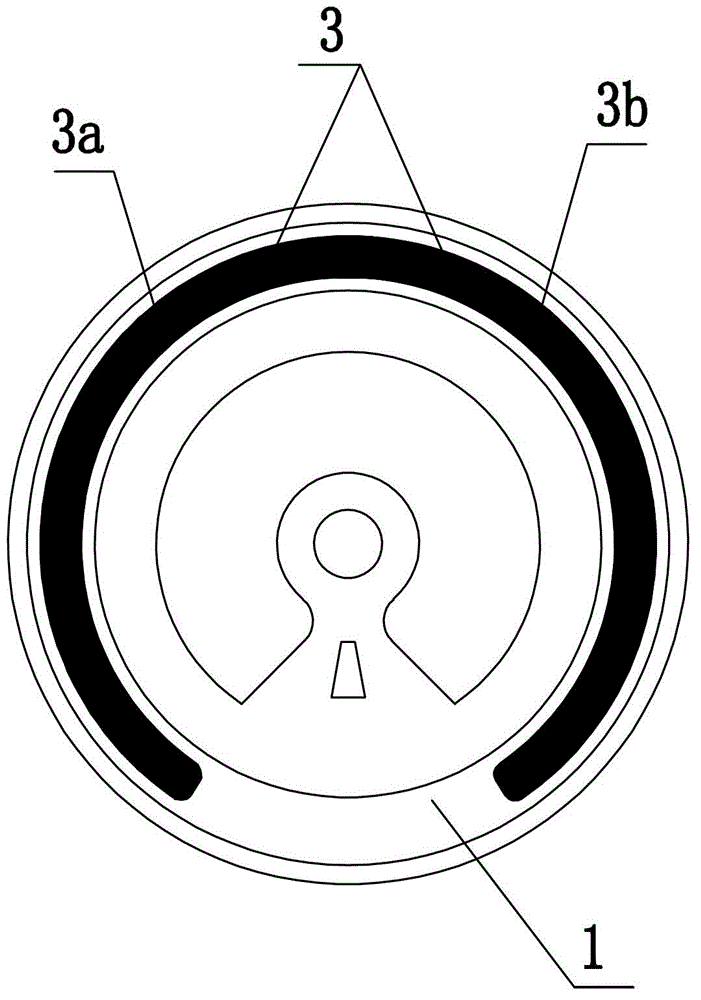

[0033] exist figure 1In the shown embodiment, a backlight indicator for a controller with a correction film includes a backlight indicator basic body 1, a backlight color gamut printing film 2 and a light transmission correction film 3, and the end surface of the backlight indicator basic body 1 is set There is a light-transmitting area 7, and the inner side of the backlight indicator basic body 1 corresponding to the light-transmitting area 7 is provided with a correction film setting area 8, which is larger than the light-transmitting area 7, and the light-transmitting area 7 is in an arc-shaped structure. Symmetrically arranged, the correction film setting area 8 is set in a ring structure, the backlight color gamut printing film 2 is printed on the light transmission area 7, and the light transmission correction film 3 is attached to the correction film setting area 8 through the adhesive layer 9 (see figure 2 ).

[0034] The basic body 1 of the backlight indicator is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com