Anti-electric shock protection structure and high voltage equipment with same

A technology of high-voltage equipment and protective structure, applied in the field of electric shock-proof structure design, can solve the problems of increasing the difficulty and cost of design and manufacture, unable to be inserted, and difficult to replace, etc., and achieve the effect of eliminating the danger of electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A specific embodiment according to the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that these drawings are only for the purpose of illustration, and are not intended to limit the protection scope of the present invention. The following description should be understood as a preferred embodiment or example of the technical solution of the present invention, the purpose of which is to describe the technical principle of the present invention more clearly, without intending to limit the protection scope of the present invention.

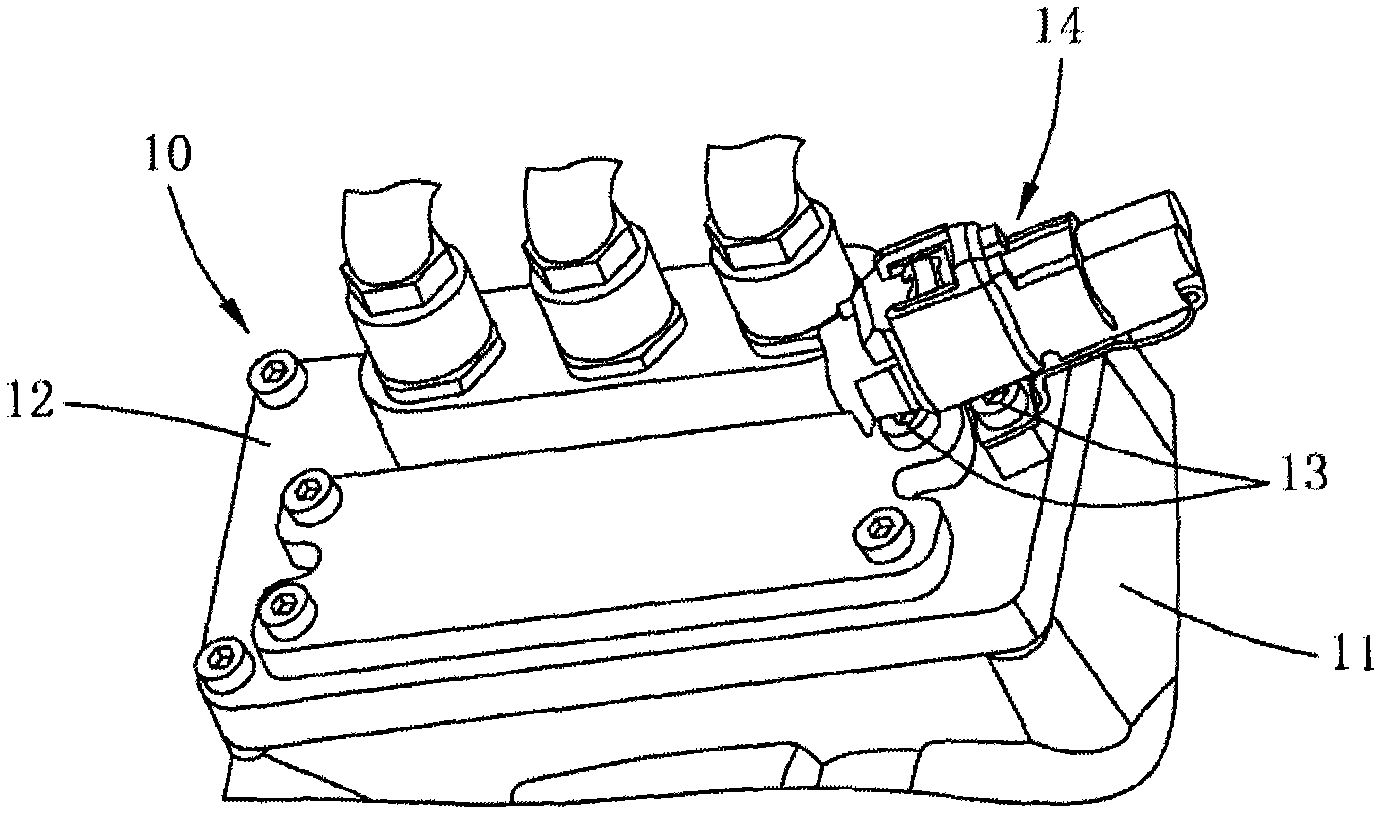

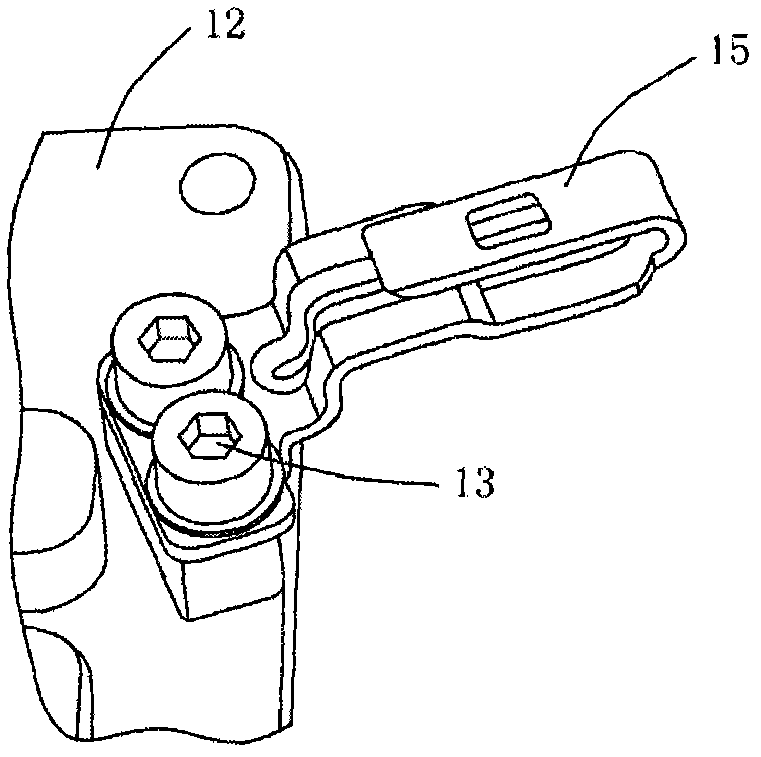

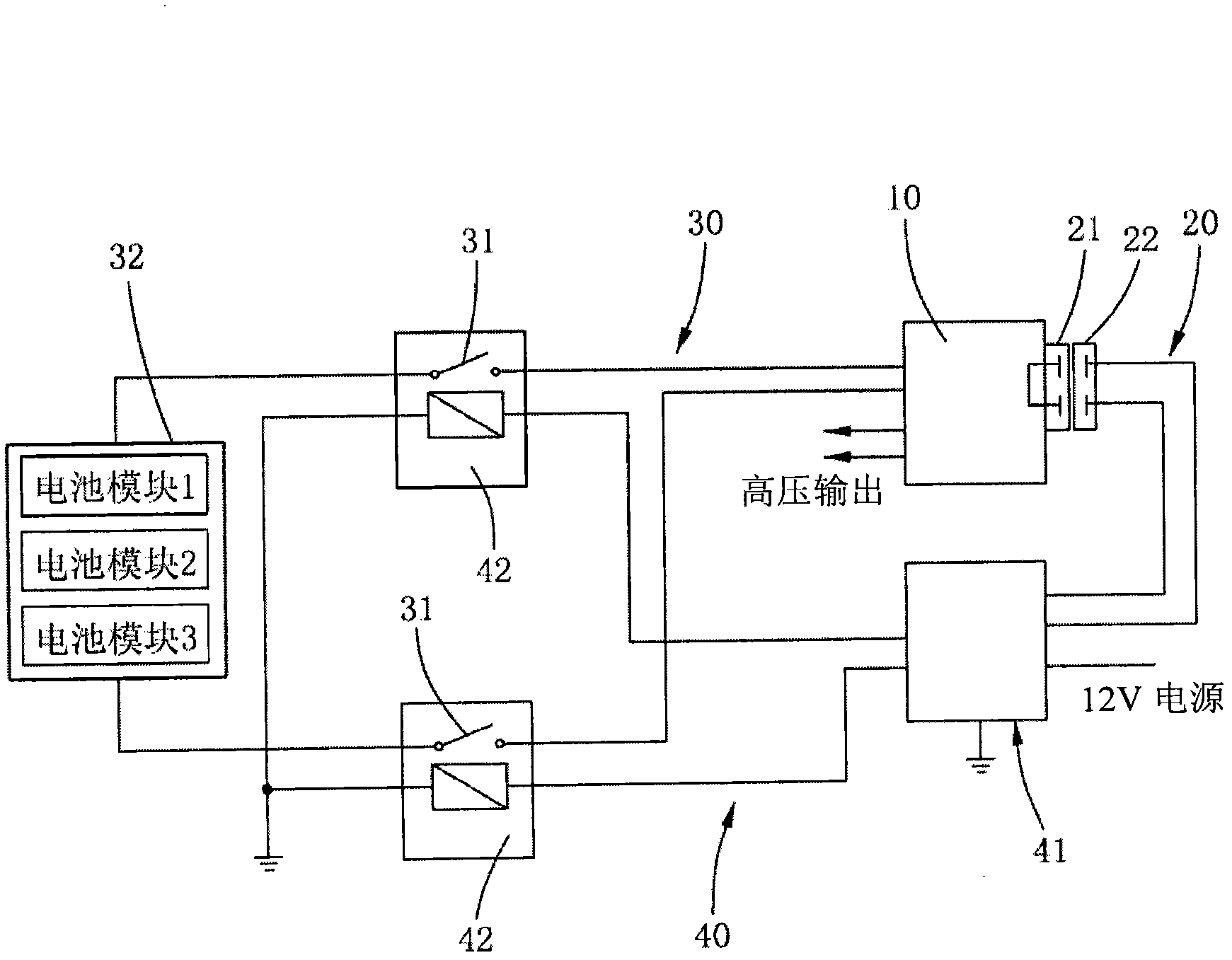

[0027] figure 1 An embodiment of the protection structure against electric shock according to the present invention is schematically shown, which is installed on high-voltage equipment. The high-voltage equipment 10 (such as a high-voltage junction box, etc.) includes a box body 11 and a box cover 12, which can effectively seal the conductors and components with high vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com