Monitoring the operating state of suspensions in an elevator system

A technology of elevators and cages, applied in elevators, transportation and packaging, etc., can solve the problems of complex structure and cost, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

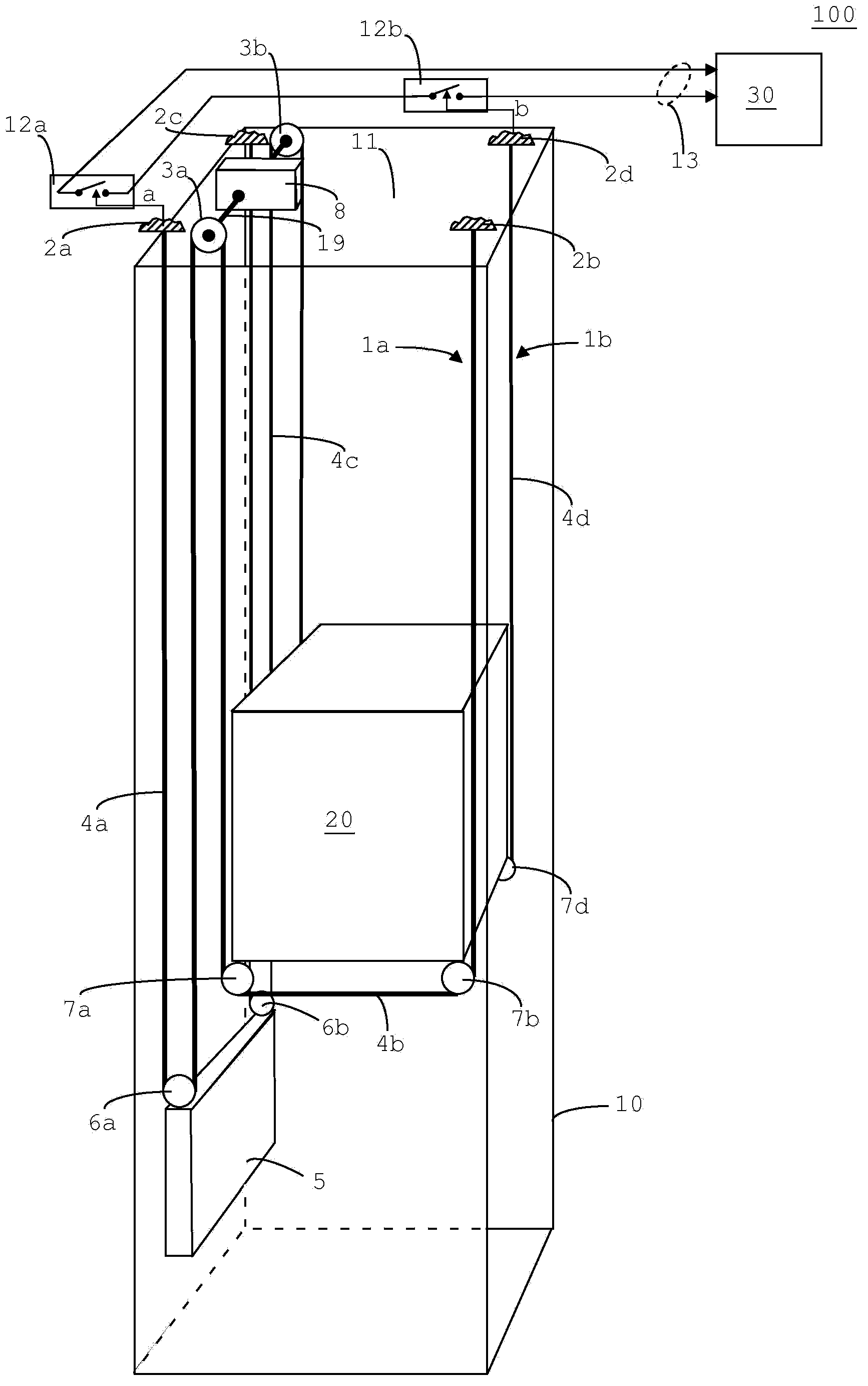

[0027] figure 1 Shown is a schematic perspective view of a part of an elevator installation 100 with two parallel-extending support elements 1a, 1b, which includes an elevator car 20 and a 2:1 arrangement (Konstellation) of countermoving arrangements. Heavy items5. A front support means 1a forms a support loop 4a from a first fastening point 2a at the shaft ceiling 11 of the elevator shaft 10 to the driving pulley 3a, in which counterweight 5 supports the rollers by means of a counterweight 6a while running. This form of suspension of the counterweight presents a 2:1 suspension.

[0028] The term "drive pulley" 3a, 3b here also refers to a drive shaft which is made in one piece and on which the two supporting means 1a and 1b run.

[0029] The support means 1a additionally forms a second support loop 4b from the driving pulley 3a to a second fixed point 2b at the shaft ceiling 11, in which the elevator car 20 is carried on the car support rollers 7a and 7b on. This type of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com