Fitted Roofing Material, Cleat, And Fitted Roof Structure

A technology of fitting and spreader, applied in the direction of roof, building structure, roof covering layer, etc., can solve the problems of the influence of the fitting state, changing the setting height of the spreader 31, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

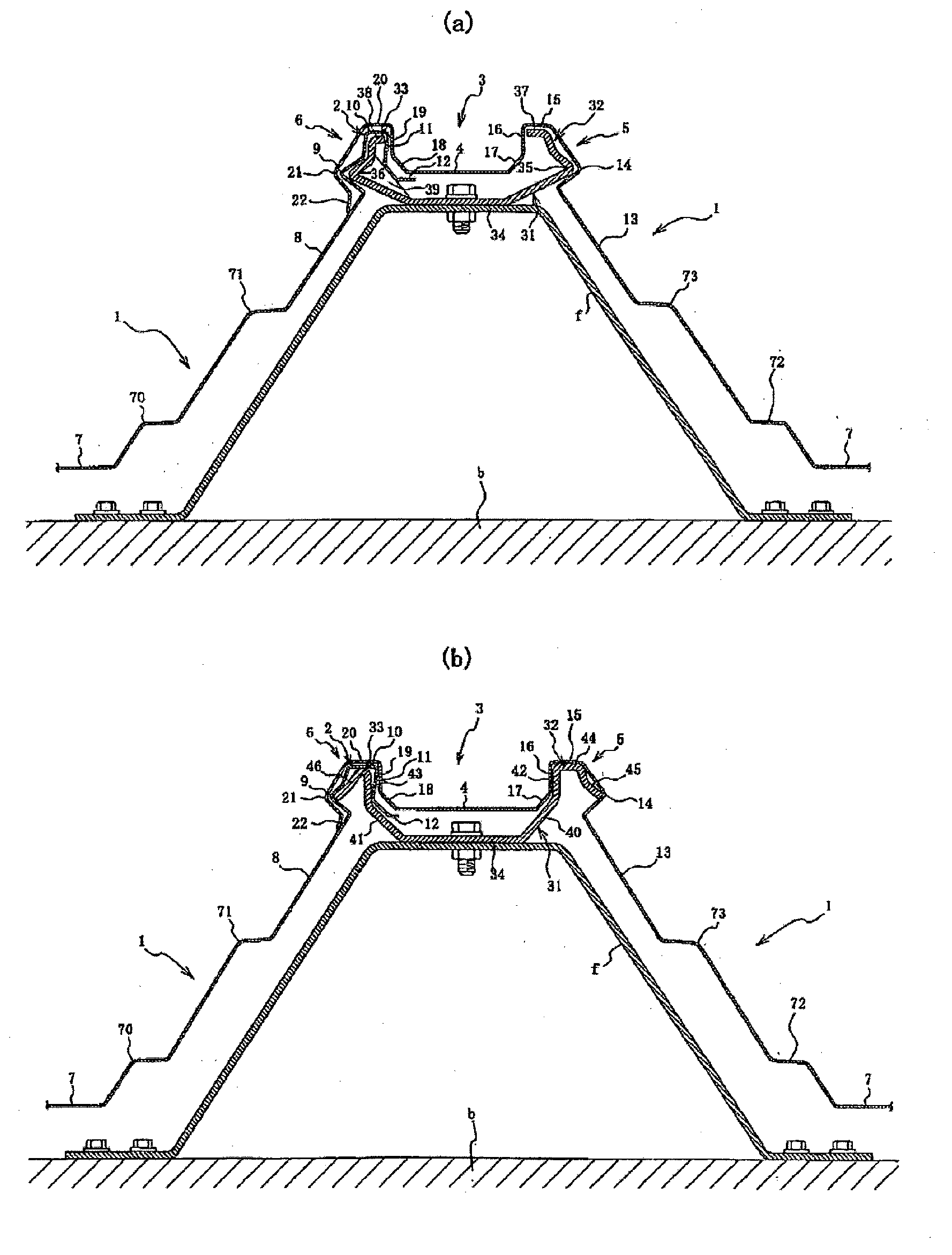

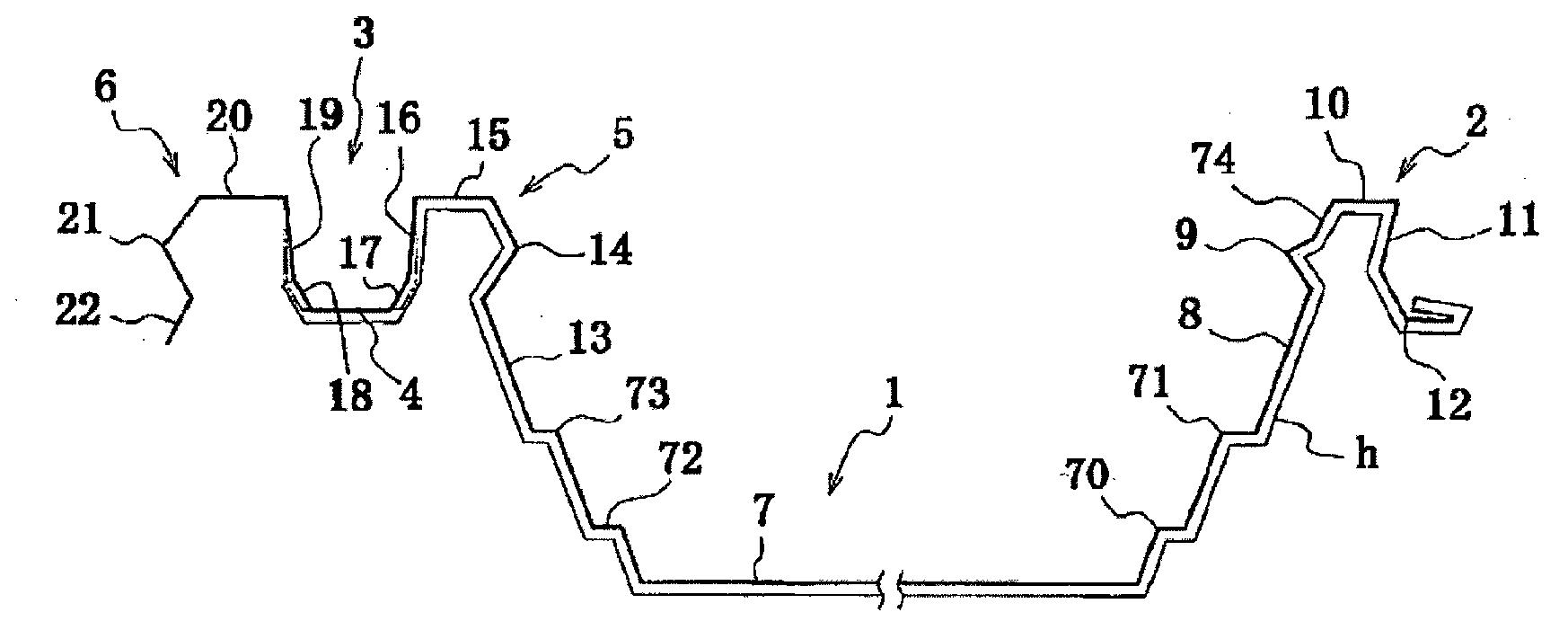

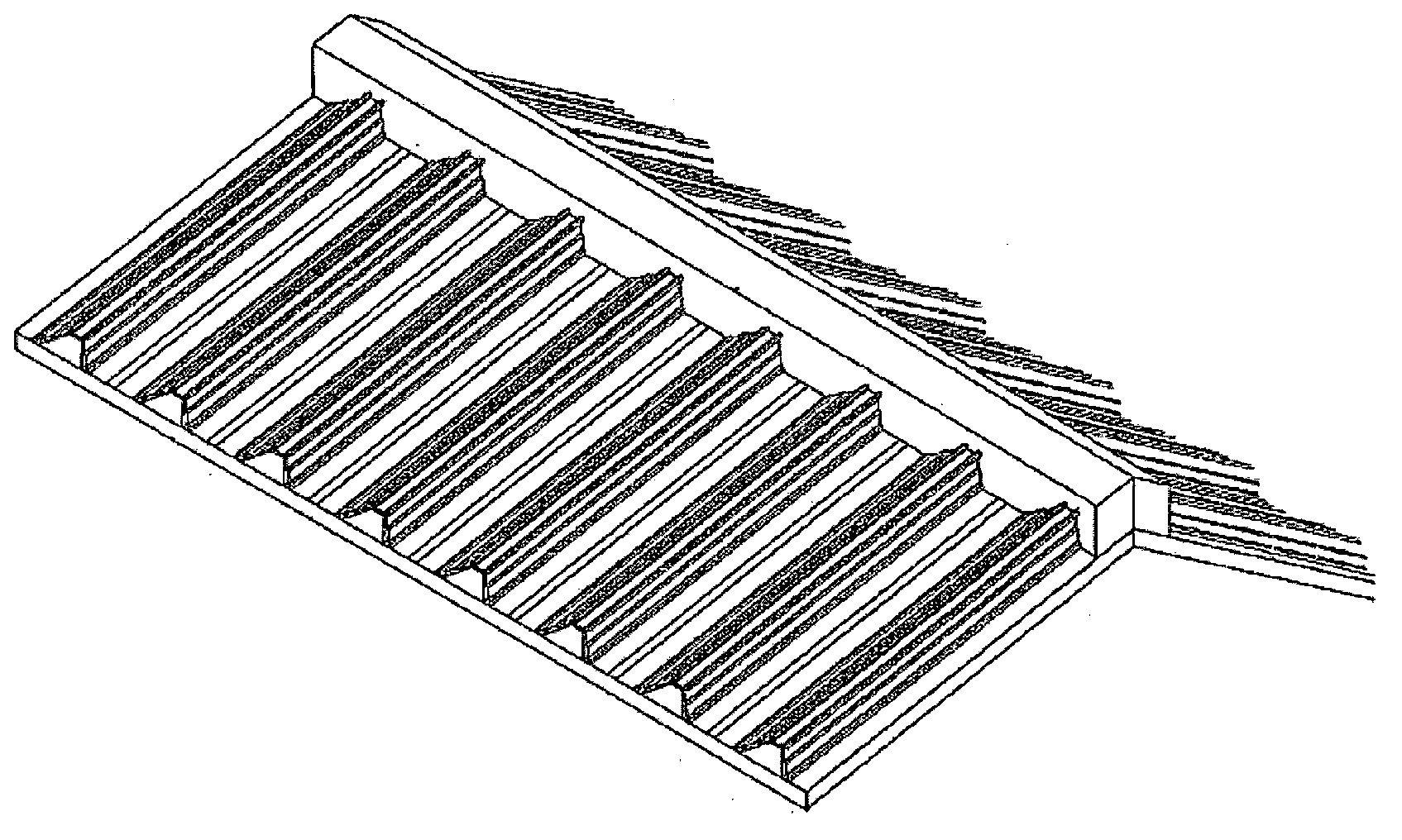

[0036] Hereinafter, the form for implementing this invention is demonstrated in detail based on drawing. Such as figure 2 As shown, the roofing material 1 according to one embodiment of the present invention is composed of a metal plate, and includes forward-inclination side fitting portions 2 formed in concavo-convex shapes along the widthwise side ends of the roofing material 1 and sleeve side fitting portions. The sleeve-side fitting portion 3 has two convex portions 5, 6 connected by the sleeve-side central concave portion 4 serving as the bottom. In the roofing material 1, the forward-inclination side fitting portion 2 of one roofing material 1 is fitted into a hanger 31 according to an embodiment of the present invention described later, and further, the sleeve-side fitting portion 3 of the other roofing material 1 is The two convex parts 5 and 6 are fitted to the hanger 31 and the forward-inclination-side fitting part 2 . Thus, the roofing material 1 is sequentially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com