Automatic brick moving device

A kind of equipment and automatic technology, which is applied in the direction of object stacking, transportation and packaging, loading/unloading, etc., can solve the problems of low handling efficiency and worker injury, so as to improve the degree of mechanization and automation, reduce enterprise costs, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

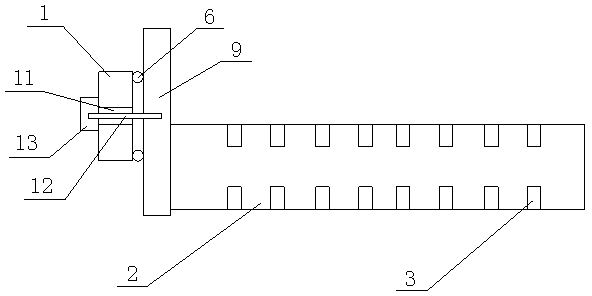

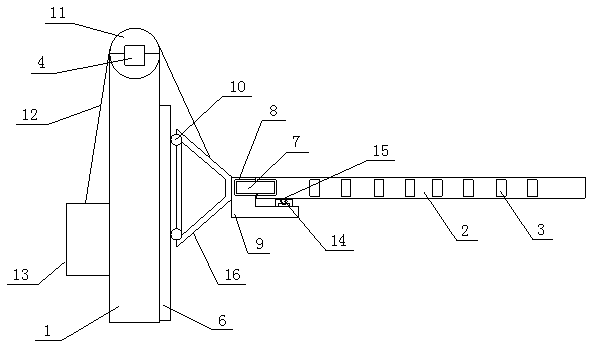

[0028] Such as Figure 1~4 As shown, the automatic brick moving equipment of the present embodiment includes a vertical support 1, and the vertical support 1 is equipped with a mechanical arm 2 that can move vertically and horizontally relative to the vertical support under the action of the mechanical arm drive mechanism; The arm 2 is provided with a plurality of mechanical claws 3 for clamping bricks, and each mechanical claw 3 is driven by an independent air cylinder.

[0029] The mechanical arm driving mechanism includes a lifting motor 4 and a translation motor 5; the vertical support 1 is provided with a vertical slide rail 6, and the end of the mechanical arm 2 is movably erected on a horizontal support 9 with a horizontal slide rail 8 through rollers 7 , the horizontal support 9 is movably mounted on the vertical slide rail 6 through rollers 10, the top of the vertical support 1 is provided with a runner 11 driven by a lifting motor 4, and the horizontal support 9 is c...

Embodiment 2

[0036] Such as Figure 5 As shown, the difference from Embodiment 1 is that the vertical support 1 of this embodiment is installed on a car body 17 with a driving mechanism and a steering mechanism. The using method of this kind of automatic brick moving equipment comprises the steps:

[0037] Control the mechanical arm 2 to move above the brick stack, use the mechanical claw 3 to clamp the bricks corresponding to the mechanical claw 3, then move the mechanical arm 2 horizontally, adjust the height of the mechanical arm 2, and move the mechanical claw 3 and its Move the clamped bricks to the top of the brick truck, and then control the movement of the car body 17 to adjust the position of the vertical support 1, so that the mechanical claw 3 holding the bricks is located at the central position of the stack of bricks on the running truck, and then loosen Open the mechanical claw 3 to make the clamped bricks fall, repeat the above steps, and gradually reduce the quantity of br...

Embodiment 3

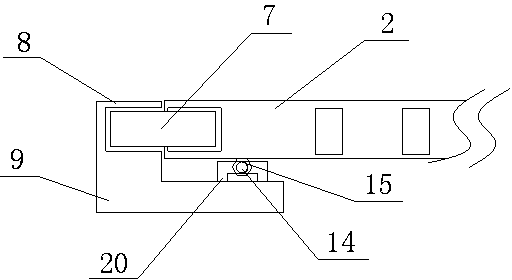

[0041] Such as Figure 6As shown, different from Embodiments 1 and 2, the mechanical arm 2 in this embodiment is provided with a horizontal guide rail 18 parallel to the axial direction of the mechanical arm 2, and the mechanical claw 3 is installed on an auxiliary bracket 19. The auxiliary bracket 19 is movably erected on the horizontal guide rail 18, and can be driven by a horizontal driving mechanism (a motor drives a belt or a screw nut is used, the horizontal driving mechanism is not shown in the figure) along the horizontal The guide rail 18 moves.

[0042] The using method of this kind of automatic brick moving equipment comprises the following steps:

[0043] Control the mechanical arm 2 to move above the brick stack, use the mechanical claw 3 to clamp the bricks corresponding to the mechanical claw 3, then move the mechanical arm 2 horizontally, adjust the height of the mechanical arm 2, and move the mechanical claw 3 and its The clamped brick moves to the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com