Planar light source apparatus and display apparatus using same

A technology of light source device and point light source, which is applied in the direction of point light source, plane/plate light guide, light source, etc., can solve the problems of low light utilization efficiency, uneven brightness, uneven light diffusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0020] Next, the structure of the display device according to the present invention will be described with reference to the drawings. Parts using the same symbols in each figure represent substantially the same structures.

[0021]

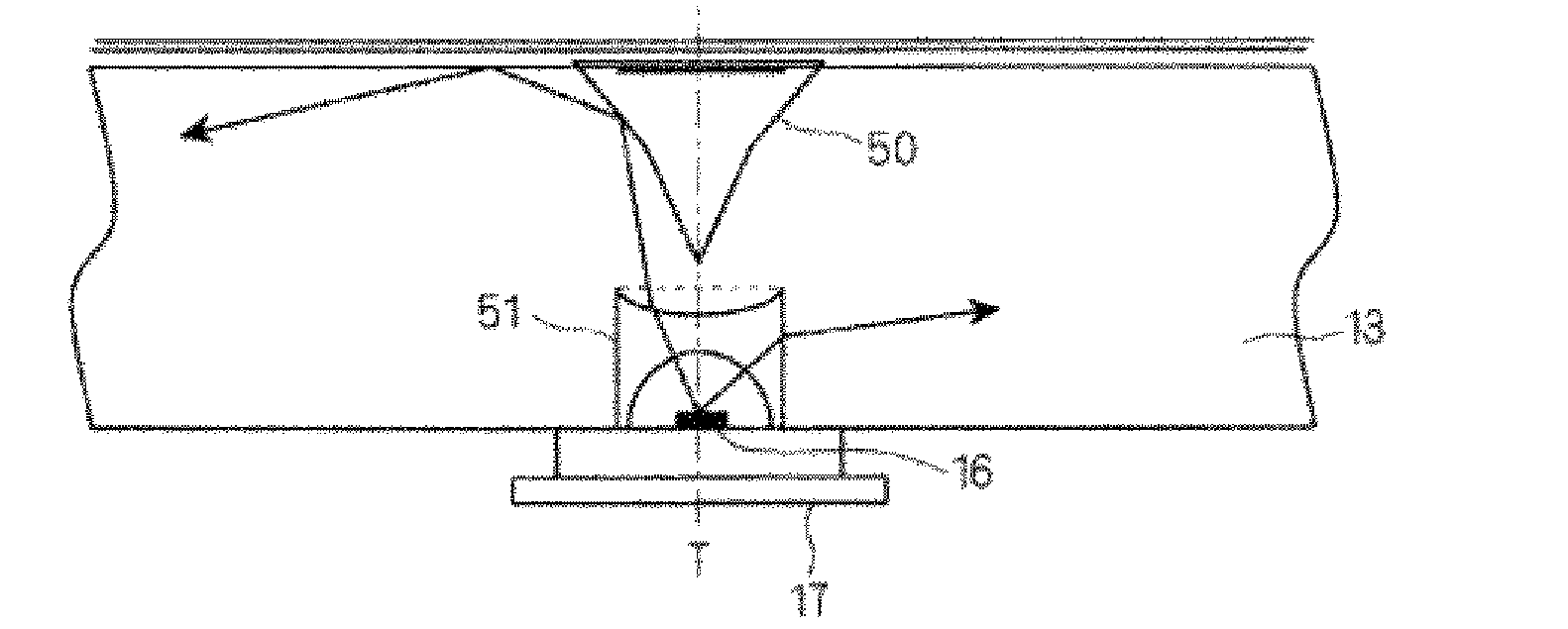

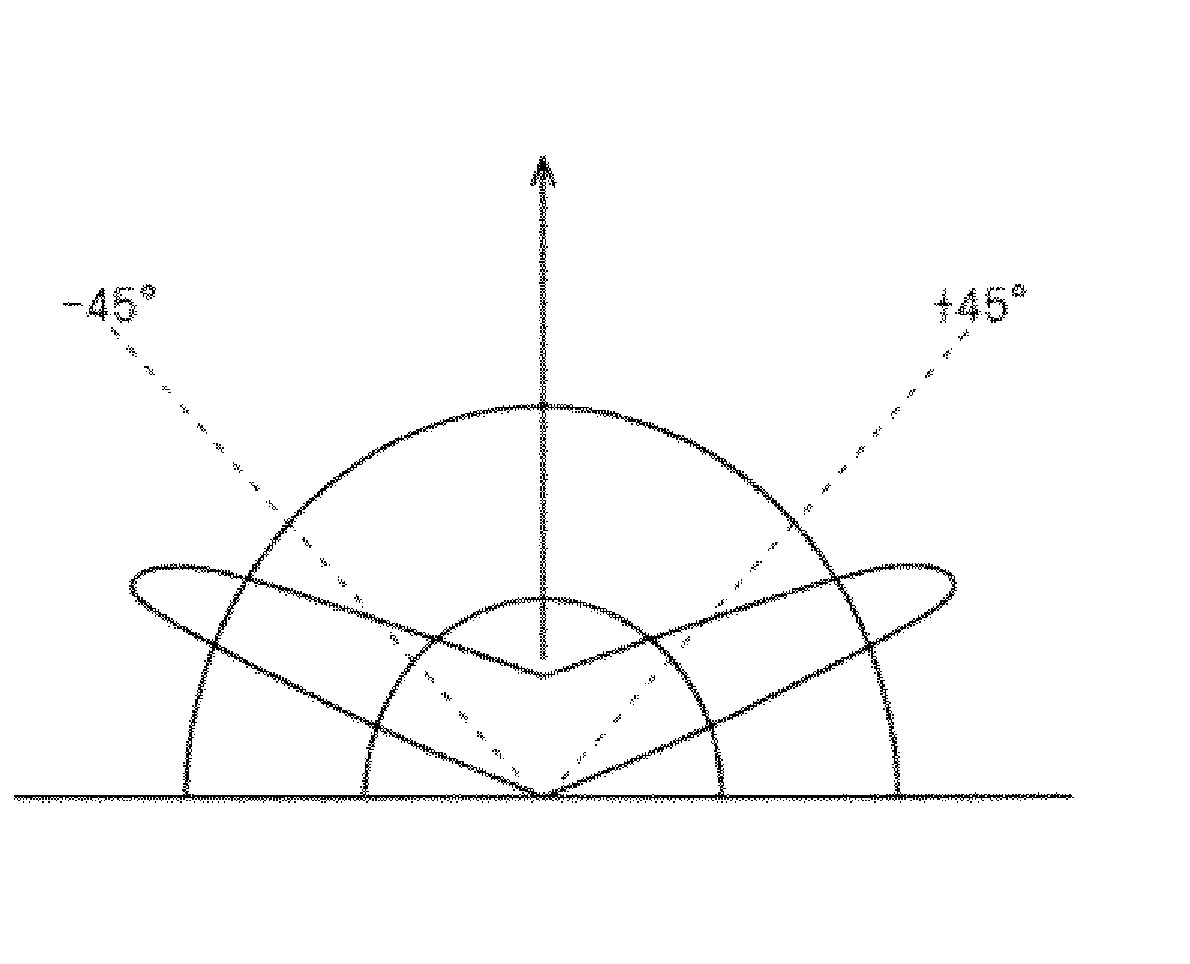

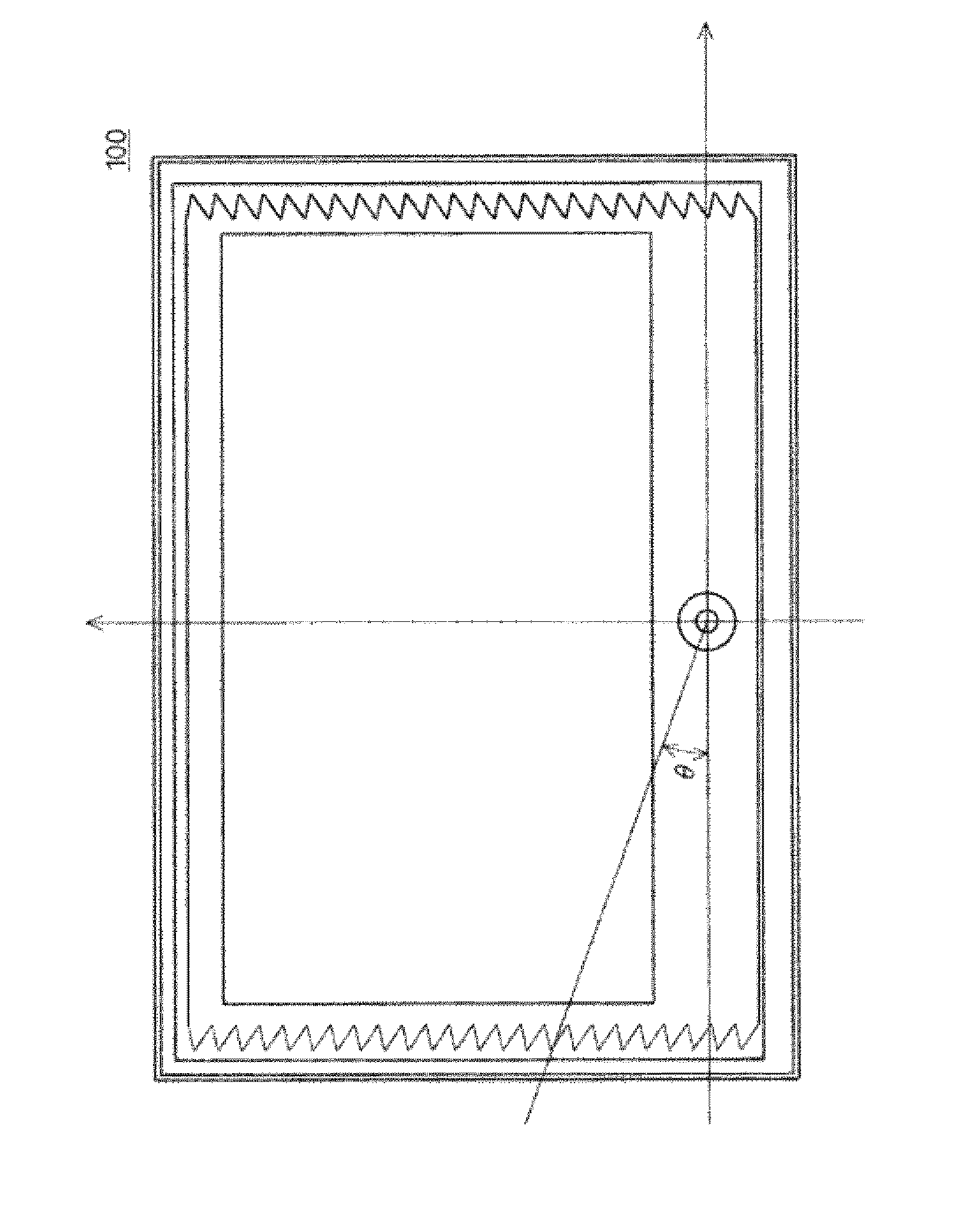

[0022] As shown in FIGS. 1 and 2 , the planar light source device 100 in the embodiment includes a light guide plate 13 that guides light into a planar shape and emits it from the emission surface, and the light guide plate 13 is disposed in a housing 10 having an opening 11. . The light is emitted in a direction having the opening 11, and this direction is taken as an emission direction. FIG. 1 is an exploded view of each component, and FIG. 2 is an overall view seen from the side of the emission surface as the emission direction. In addition, a point light source 16 is arranged in a housing portion formed on the bottom surface of the housing 15 facing the surface having the opening 11 of the housing 10 .

[0023] A diffusion plate (not show...

Embodiment approach 2

[0069]

[0070] The configuration of the planar light source device 100 according to Embodiment 2 will be described below. Here, the parts other than the shape of the second side surface 13 b of the light guide plate 13 are the same as those of the first embodiment, and thus description thereof will be omitted.

[0071] FIG. 7 shows a front view of planar light source device 100 according to Embodiment 2, and FIG. 8 shows a prism detail view of second side surface 13 b of light guide plate 13 in planar light source device 100 . In addition to the specific functions and effects of the planar light source device 100 according to the second embodiment described below, the same functions and effects as those of the planar light source device 100 according to the first embodiment are achieved.

[0072] In Embodiment 1, all the shapes of the prisms are the same, but in Embodiment 2, it is as shown in FIG. 7 .

[0073] That is, the angle between the side B and the reflected point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com