Method for driving display

A driving method and display technology, applied in static indicators, instruments, semiconductor lamps, etc., can solve problems such as uneven brightness, critical voltage shift of thin film transistors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The "electroluminescence display and its driving method" of the present invention is described in detail with the drawings, and the preferred

[0043] Embodiment description is as follows:

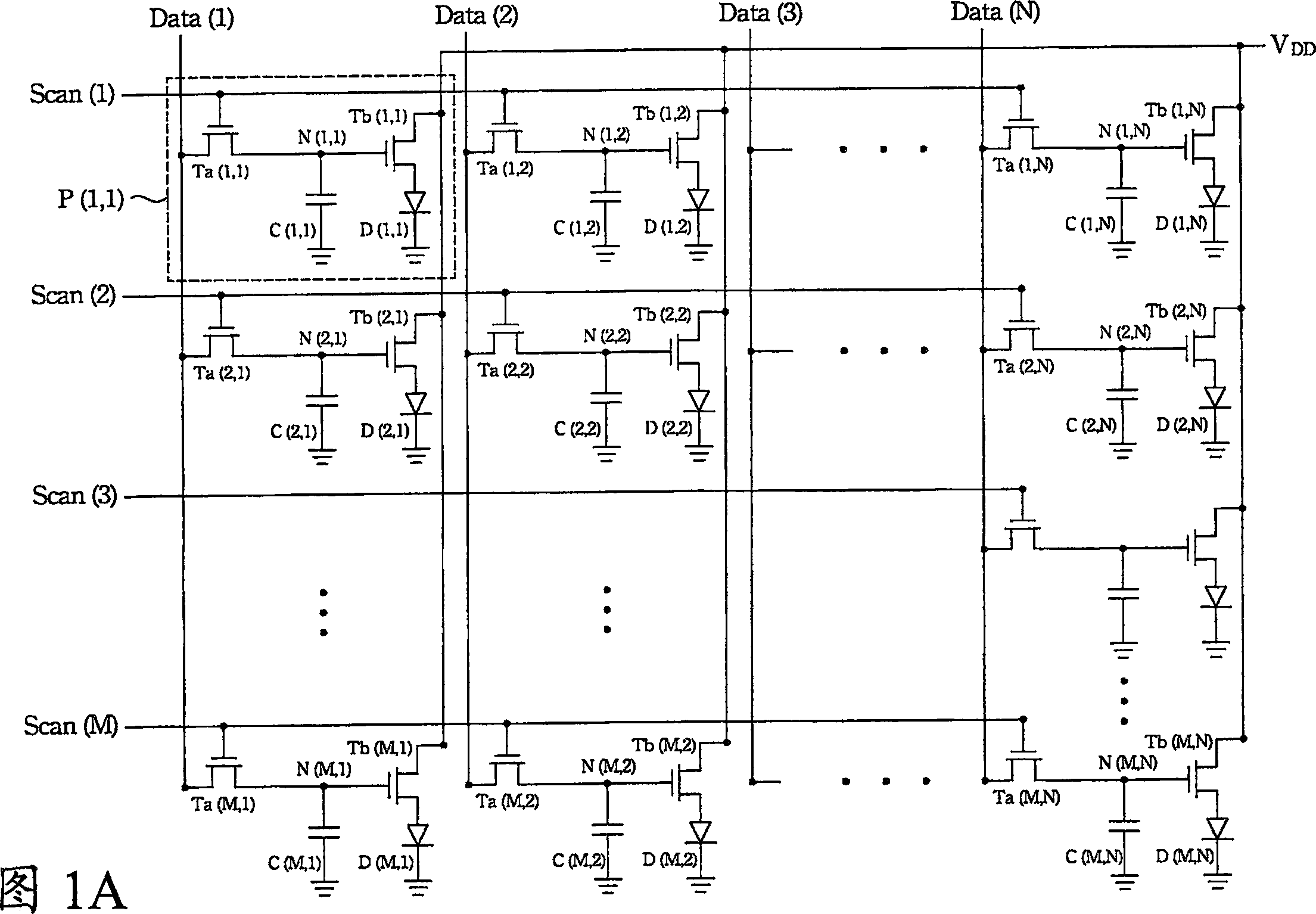

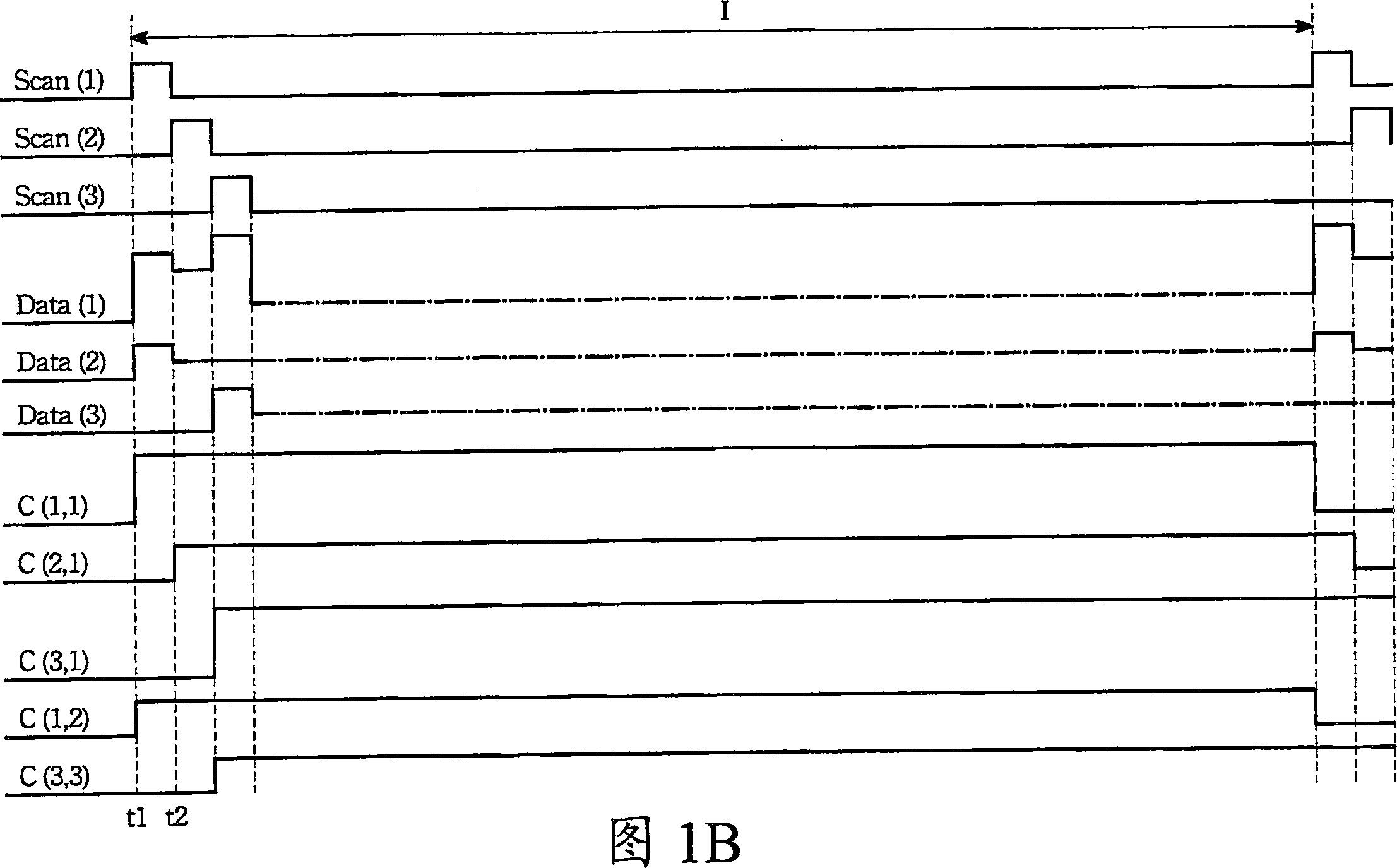

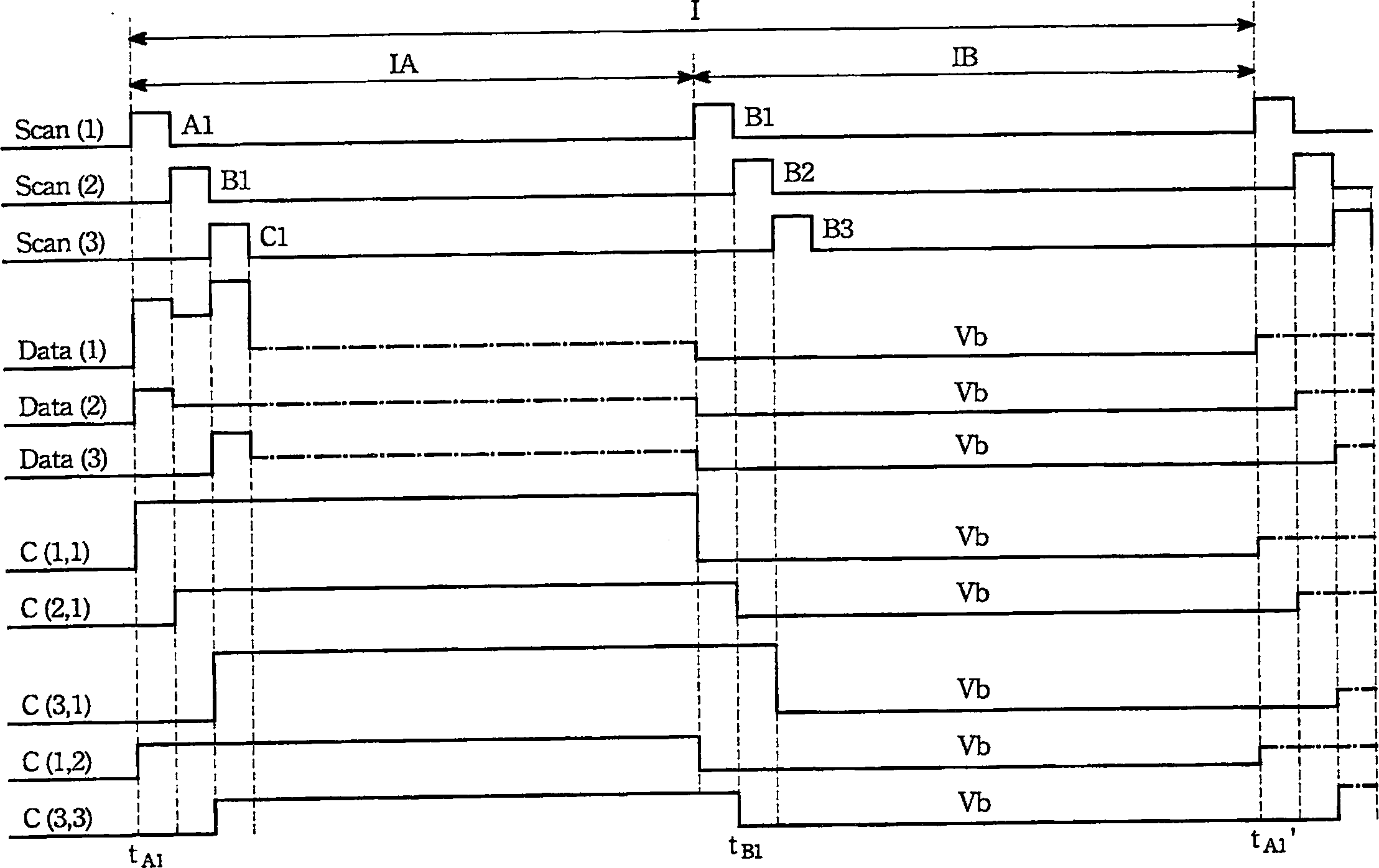

[0044] In the electroluminescence display of the present invention, the circuit diagram of the OLED pixel array and its pixel structure are shown in FIGS. 2A-2B . The electroluminescent display has M scanning lines Scan, N data lines Data and a pixel array of M columns and N rows. The pixel array has M×N pixels for displaying a frame in a display period. Each pixel P has a switching transistor Ta, a driving transistor Tb, a light emitting unit D and a capacitor C. As shown in FIG. The source S and the gate G of the switch transistor Ta are respectively connected to a data line Data and a scan line Scan. The drain and source S of the driving transistor Tb are respectively electrically connected to a display voltage source V DD And the light emitting unit D, the gate G of which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com