Backlight assembly and liquid crystal display module

A technology of backlight components and liquid crystal panels, applied in optics, nonlinear optics, instruments, etc., can solve the problem of uneven brightness of bright and dark frames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

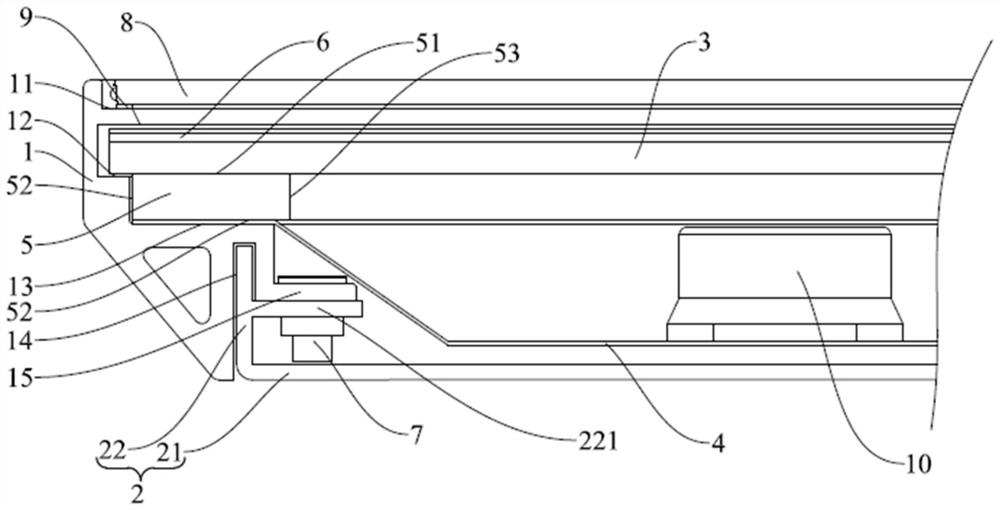

[0058] Such as Figure 1-Figure 3 As shown, the liquid crystal display module of this embodiment includes a backlight assembly and a liquid crystal panel 8 fitted on the backlight assembly.

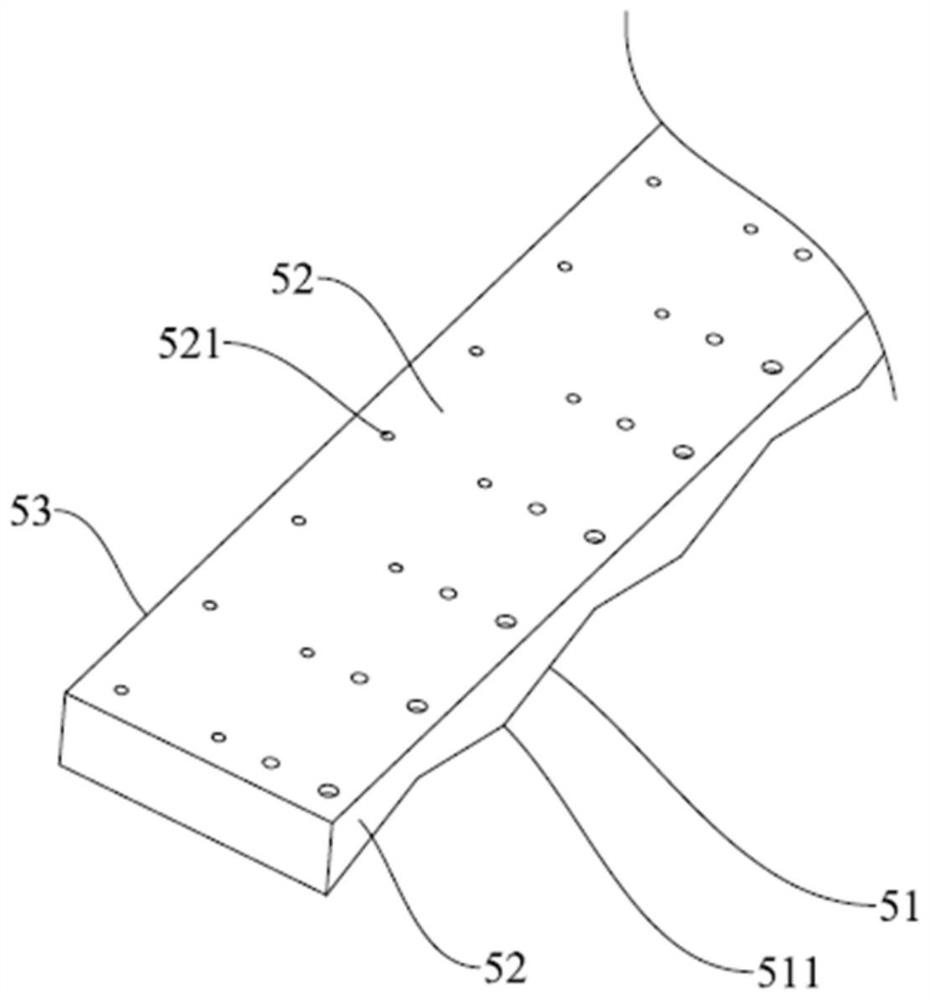

[0059] The backlight assembly includes a middle frame 1, a back plate 2, a diffusion plate 3, a reflection sheet 4, a light guide unit 5, and an optical film 6. The middle frame 1 has a first support step 11 and a second support step 12 arranged in sequence from front to back. , the third support step 13 and the first support step 11 , and the middle frame 1 is also provided with an insertion slot 14 . The liquid crystal panel 8 is bonded on the first supporting step 11 through the foam glue 9 .

[0060] The backplane 2 includes a flat panel 21 and a plug-in flange 22. The flat panel 21 is provided with a plurality of light sources 10. The plug-in flange 22 is arranged around the flat panel 21. The plug-in flange 22 is plugged into the socket of the middle frame 1. Inside the slot 14 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com