I-grade and II-grade curing extruder suitable for non-fried side crop instant noodles

A non-fried, instant noodle technology, applied in the direction of dough extruder, etc., can solve problems such as uneven distribution of noodle strip edges, unqualified noodle cake size, and affecting processing efficiency, so as to prevent sticking to boxes and prevent gelatinization of miscellaneous grain materials , the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

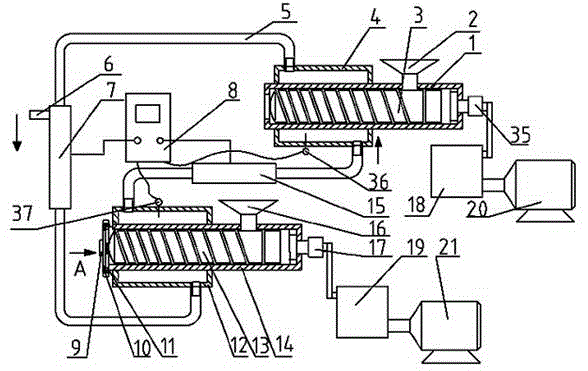

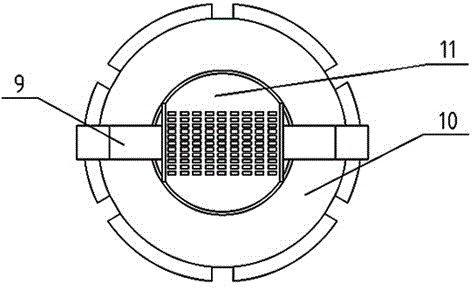

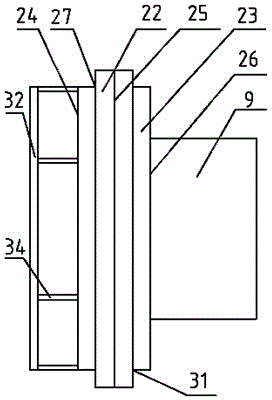

[0023] Such as figure 1 with figure 2 As shown, the Ⅰ and Ⅱ stage ripening extruder suitable for non-fried miscellaneous grain instant noodles, it includes the Ⅰ stage extrusion sleeve 1, the cooler 7, the Ⅱ stage extrusion sleeve 14 and the heater 15, the Ⅰ stage extrusion sleeve The sleeve 1 is equipped with a Class I circulating water jacket 4, and a Class I temperature sensor 36 is installed inside the Class I circulating water jacket 4. The Class I temperature sensor 36 is connected to the external integrated control cabinet 8. There is an I-stage feed hopper 2, an I-stage extrusion sleeve 1 is coaxially fitted with an I-stage extrusion screw 3, and the end of the I-stage extrusion screw 3 is connected with an I-stage coupling 35, and the I-stage coupling A grade I re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com