Handle mounting structure of overhead guard of forklift

A technology of installation structure and roof guard, which is applied to the special position of the vehicle, lifting device, vehicle parts, etc., can solve the problems of affecting normal use and easy loosening of mounting bolts, etc., to ensure normal use, prevent handles from loosening, The effect of increasing the force contact surface

Inactive Publication Date: 2013-01-16

无锡泰立特科技有限公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In view of the above problems, the present invention provides a handle installation structure of a forklift roof guard, which can solve the problem that the installation bolts in the existing handle installation structure are easy to loosen and fall off, which affects normal use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

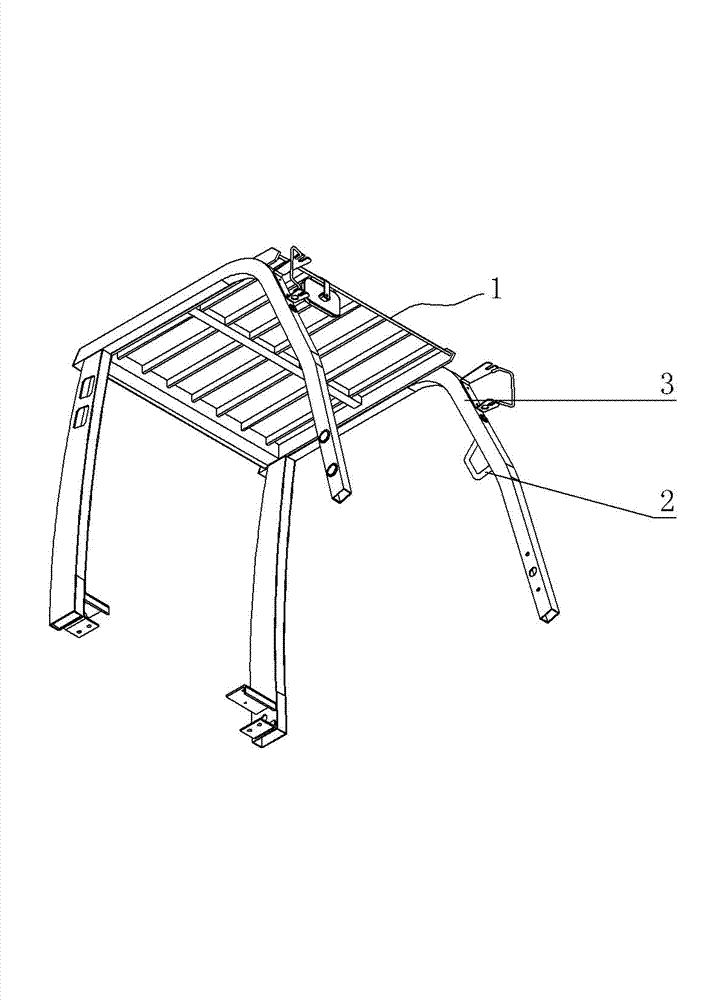

[0009] See figure 2 , the present invention includes a roof guard 1 and a handle 2, and the handle 2 is welded to the back of the front leg 3 of the roof guard 1. Wherein, the handle 2 is formed by directly bending the steel pipe, and compared with the conventional handle 2, the molded part is used, which can reduce the cost.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a handle mounting structure of the overhead guard of a forklift. The handle mounting structure can solve the problem in the existing handle mounting structures that mounting bolts are vulnerable of loosing and falling off. The handle mounting structure comprises an overhead guard and a handle, and is characterized in that the handle is welded on the front landing leg of the overhead guard.

Description

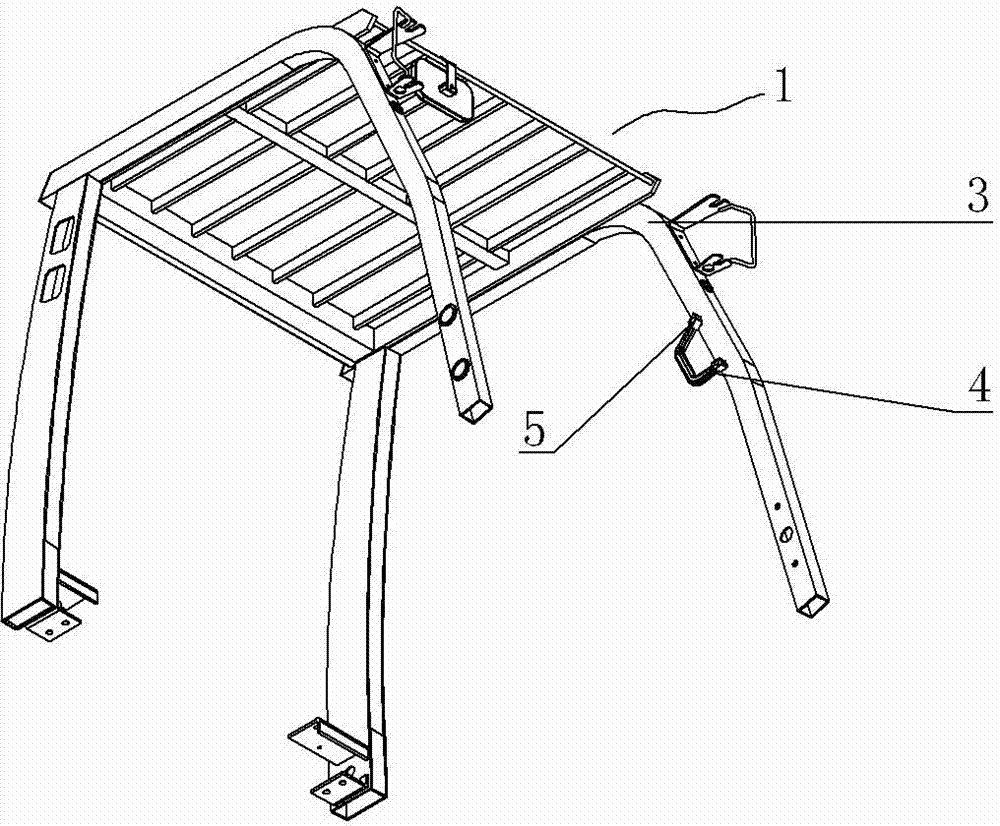

technical field [0001] The invention relates to the field of forklift manufacturing, in particular to a handle installation structure of a forklift roof guard. Background technique [0002] The upper handle 5 of a traditional forklift is to adopt a molded part to be installed on one side of the front leg 3 of the forklift roof guard 1 through bolts 4, see figure 1 , its function as a force-bearing part is to facilitate the driver to get on the car with his hand when getting on the car, but because the front leg of the roof guard is generally made of a 3mm thick rectangular pipe, the installation wall of the handle is relatively thin , and because the handle is installed on one side of the front leg of the roof guard through bolts, not only the force contact area between the bolts and the installation wall is small, but also the bolts bear the pulling force along the tangential direction of the installation wall surface, after long-term use The handle is prone to loose bolts...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B66F9/075B60N3/02

Inventor 吴坚朱鲲鹏

Owner 无锡泰立特科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com