Method for determining centrifugal pump full-condition theoretical lifts based on internal flow measurement

A determination method, a technique of internal flow measurement, applied in pump control, non-variable displacement pumps, machines/engines, etc., can solve problems such as not considering the influence of the peripheral speed at the impeller inlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

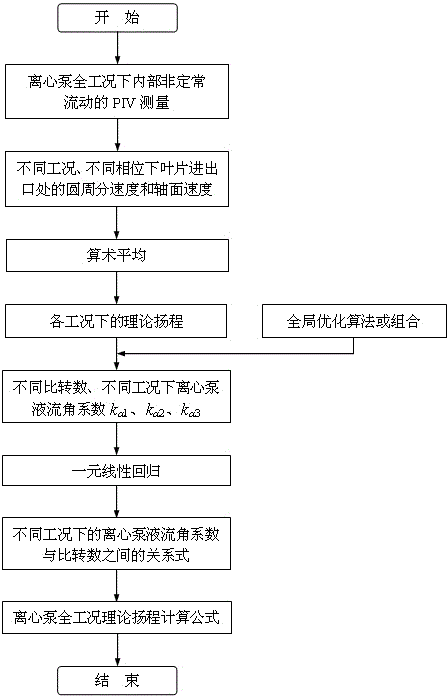

Method used

Image

Examples

Embodiment

[0026] (1) PIV experiments are used to measure the internal unsteady flow laws of centrifugal pumps under three working conditions.

[0027] For a double-vane centrifugal pump with a specific speed of 115.6, its performance parameters under three working conditions are: 0.8 times the design working condition Q 1 =27.56m 3 / h, H 1 =4.96m, n 1=56.32%; design conditions Q 2 =34.48m 3 / h, H 2 =4.50m, n 2 =58.48%; 1.2 times design conditions Q 3 =41.40m 3 / h, H 3 =4.03m, n 3 =57.89%.

[0028] 1) Selection of measurement area and tracer particles.

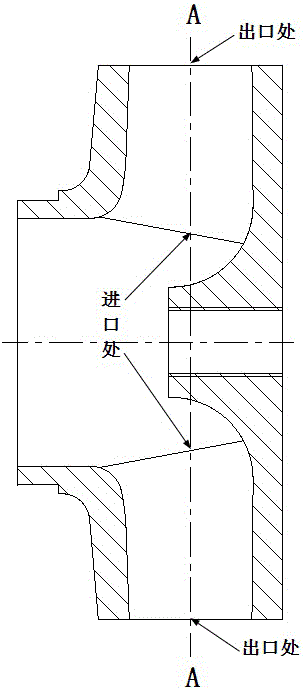

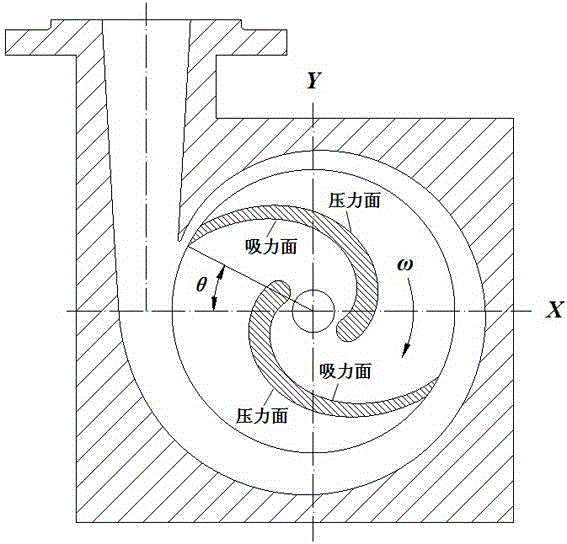

[0029] Select the middle section A-A of the impeller (such as figure 2 shown) is the measurement plane. The impeller rotates clockwise, the angular velocity ω is 10.5rad / s, the suction surface of the blade facing the tongue and the X Angle between axes θ =28°, such as image 3 shown. Six different phases are measured in each working condition, which are recorded as φ / 6, φ / 3, φ / 2, 2 φ / 3,5 φ / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com