Hot work bending technology for spatial hyperbolic circular tube

A hyperbolic circle and pyrotechnic technology, which is applied in the field of space hyperbolic circular pipe pyrotechnic bending, can solve the problems of poor bending quality and high labor intensity, and achieve strong pipe bending ability, low labor intensity, and high production efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

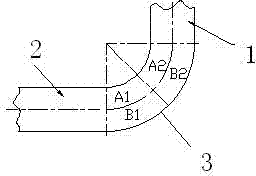

Image

Examples

Embodiment 1

[0018] A space hyperbolic circular pipe pyrotechnic bending process in this embodiment includes the following steps: 1) steel pipe blanking and groove processing , According to the design drawings and processing technology requirements, and considering the length of the straight pipe and the length of the bent part to determine the blanking size of the steel pipe; 3) Bend pipe correction, using one or more of flame correction, flame plus external force jack correction, and flatness flame correction.

[0019] Step 1) After blanking is completed, mark the steel pipe, and the marking requirements are as follows.

[0020] Marking content: drawing number / total number of paragraphs—what paragraph, process length.

[0021] Marking requirements: The writing of the paint is correct and clear.

[0022] Marking position: The lower end of each steel pipe is 100mm away from the port, and the range of (80-100)×(400-500) mm2 is used for marking.

[0023] Port alignment reference mark: Mar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com