Filler arranging device

A sorting device and filler technology, which is applied in the direction of processing textile materials, equipment configuration, etc., can solve the problems of water droplets falling, affecting the quality of textiles, affecting the concentration of solution in the cabin, etc., and achieve the effect of reducing the pressure in the cabin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

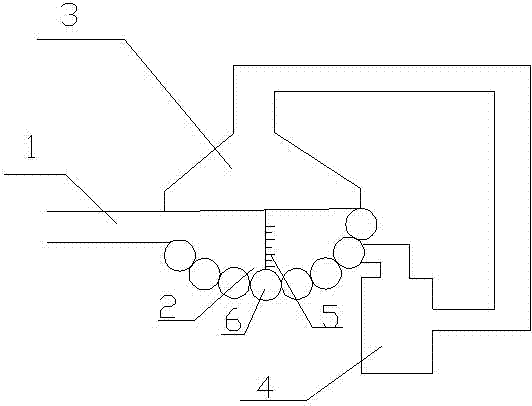

[0008] A filler sorting device, the stuff sorting device includes a feed pipe 1, a sorting cabin 2, a gas collecting cover 3, and a waste liquid collection bottle 4, one end of the sorting cabin 2 is connected to the feed pipe 1, and the other end is connected to the waste liquid collection bottle 4 The cover of the gas collecting hood 3 covers the finishing cabin 2, and is connected to the waste liquid collection bottle 4 through a pipeline. When in use, the material enters the finishing cabin 2 from the feed pipe 1, and the roller 6 at the bottom of the finishing cabin 2 rolls to drive the material to rotate, so that the material can be soaked more thoroughly in the finishing process, and the waste liquid collection bottle can collect excess residue. , the gas collecting hood 3 can collect the medicinal liquid water vapor obtained by the reaction in the finishing cabin, and enter the waste liquid collection bottle through condensation to reduce the pressure in the cabin. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com