Airplane windscreen

A windshield and aircraft technology, which is applied in the field of aircraft, can solve the problems of aircraft windshield failure and poor safety performance, and achieve the effect of delaying the time of falling out of the frame, reducing the height and maintaining the integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

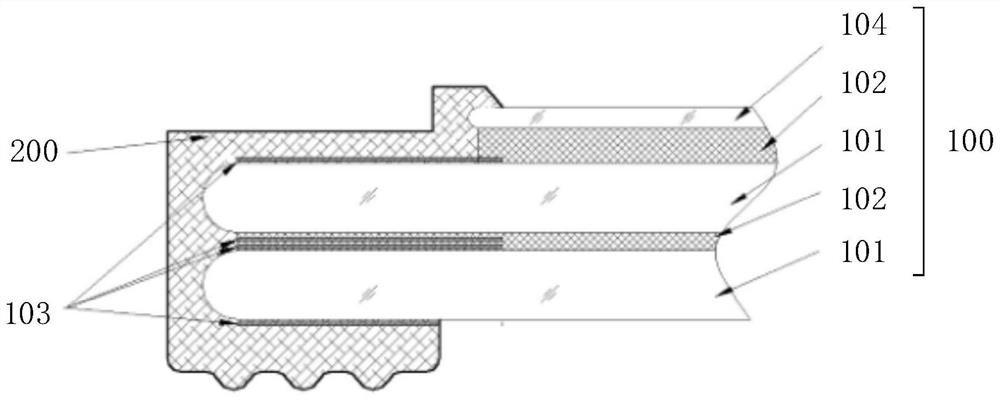

[0025] Such as figure 1 The aircraft windshield shown in this embodiment includes a transparent composite panel element 100 and an edge connector 200, wherein the edge connector 200 is installed outside the edge of the transparent composite panel element 100 and covers the transparent composite panel element 100 The two outer surfaces of the area near the edges. The transparent composite panel element 100 comprises at least two first transparent layers 101 , at least one second transparent layer 102 and at least two annular reinforcement layers 103 . A second transparent layer 102 is bonded between two adjacent first transparent layers 101 , and a ring-shaped reinforcing layer 103 is bonded to two surface areas near the edges of at least one first transparent layer 101 .

[0026] In this embodiment, the edge connector 200 is installed outside the edge of the transparent composite panel element 100, and is fixedly connected with the supporting window frame 300 of the aircraft ...

Embodiment 2

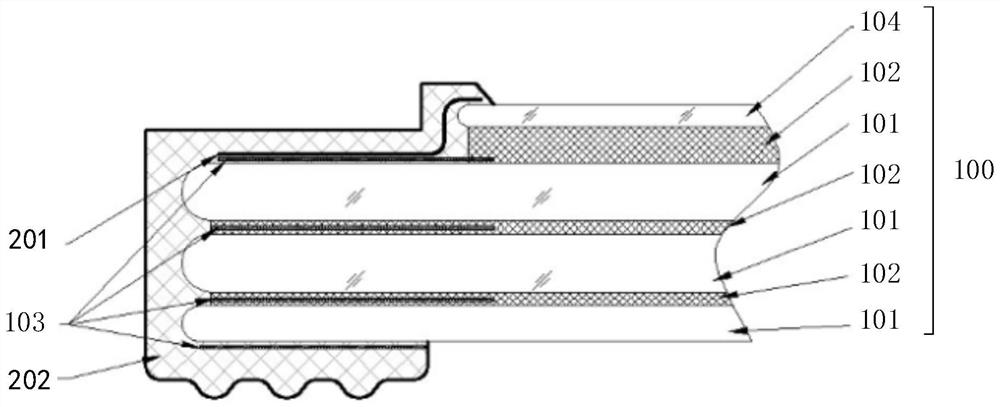

[0058] Such as figure 2 As shown in the aircraft windshield, the aircraft windshield in this embodiment includes a transparent composite panel element 100 and an edge connector 200, wherein the transparent composite panel element 100 includes at least two first transparent layers 101 and at least one second transparent layer 102 , a third transparent layer 104 and at least two annular reinforcing layers 103 . A second transparent layer 102 is bonded between two adjacent first transparent layers 101 , and a ring-shaped reinforcing layer 103 is bonded to two surface areas near the edges of at least one first transparent layer 101 . One surface of a first transparent layer 101 is the first outer surface of the transparent composite panel element 100 . Two surfaces of a second transparent layer 102 are respectively bonded with a third transparent layer 104 and a first transparent layer 101 , and one surface of the third transparent layer 104 is the second outer surface of the tr...

Embodiment 3

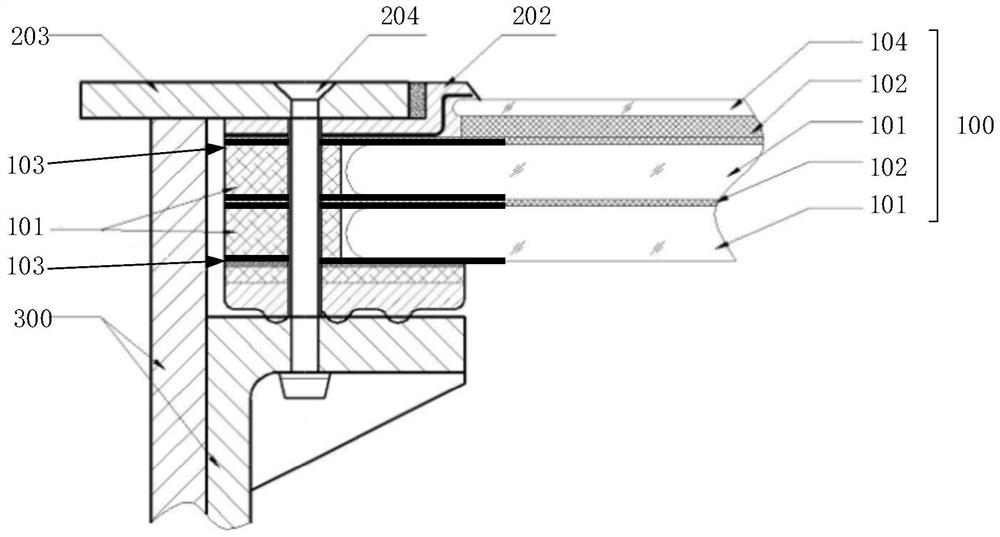

[0077] Such as image 3 and Figure 4 The shown aircraft windshield comprises a transparent composite panel element 100 and an edge connector 200, wherein the transparent composite panel element 100 comprises at least two first transparent layers 101, at least one second transparent layer 102, and a third transparent layer 104 And at least two ring-shaped reinforcing layers 103; the material of the middle area of the first transparent layer 101 is different from that of the edge area, and a second transparent layer 102 is bonded between two adjacent first transparent layers 101, and at least one of the first transparent layers 101 Two surfaces of a transparent layer 101 close to the edge region are respectively bonded with an annular reinforcing layer 103; a surface of a first transparent layer 101 is the first outer surface of the transparent composite plate element 100; a second transparent layer 102 A third transparent layer 104 and a first transparent layer 101 are bond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com