Annular iron inner core of rubber belt track

A rubber crawler and ring-shaped technology, which is applied in the drive field of construction machinery operations, can solve problems such as lateral dislocation, rubber crawler derailment, and affect the normal operation of construction machinery, so as to achieve uniform driving force, prevent crawler derailment or lateral displacement, and reduce machine vibration and bumpy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

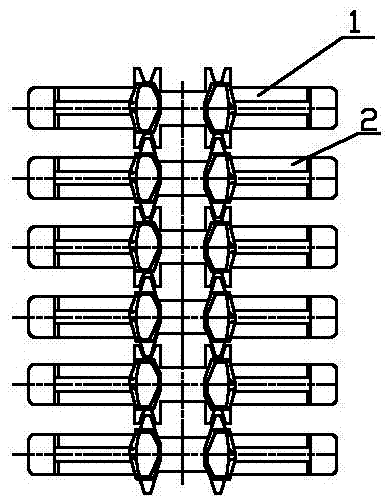

[0023] Such as figure 1 As shown, the utility model is composed of first iron teeth 1 and second iron teeth 2 arranged at intervals and engaged with each other.

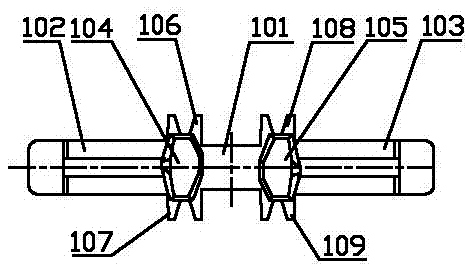

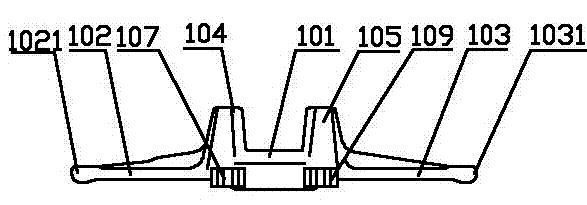

[0024] Such as figure 2 , 3 As shown, the first iron tooth 1 is provided with a first driving bridge 101 , and a first left wing 102 and a first right wing 103 are respectively extended on the left and right ends of the first driving bridge 101 .

[0025] The free end of the first left wing 102 is provided with an arc-shaped outer contour surface 1021 ; the free end of the first right wing 103 is provided with an arc-shaped outer contour surface 1031 .

[0026] A first left tooth tip 104 is provided between the first drive bridge 101 and the first left wing 102, a first right tooth tip 105 is provided between the first drive bridge 101 and the first right wing 103, and the first left tooth The tip 104 and the first right tooth tip 105 respectively protrude from the same side of the first drive bridge 101 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com