Agitator tools for stand mixers including scrapers

A technology of agitator and mixer, applied in the field of agitator components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

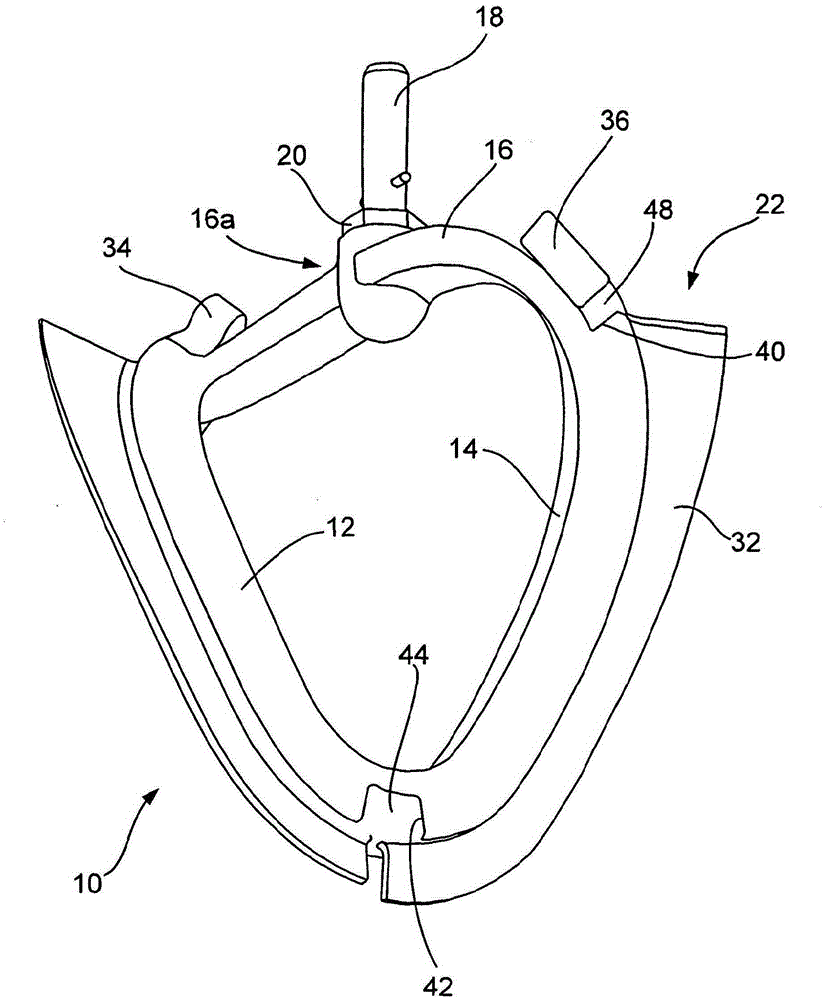

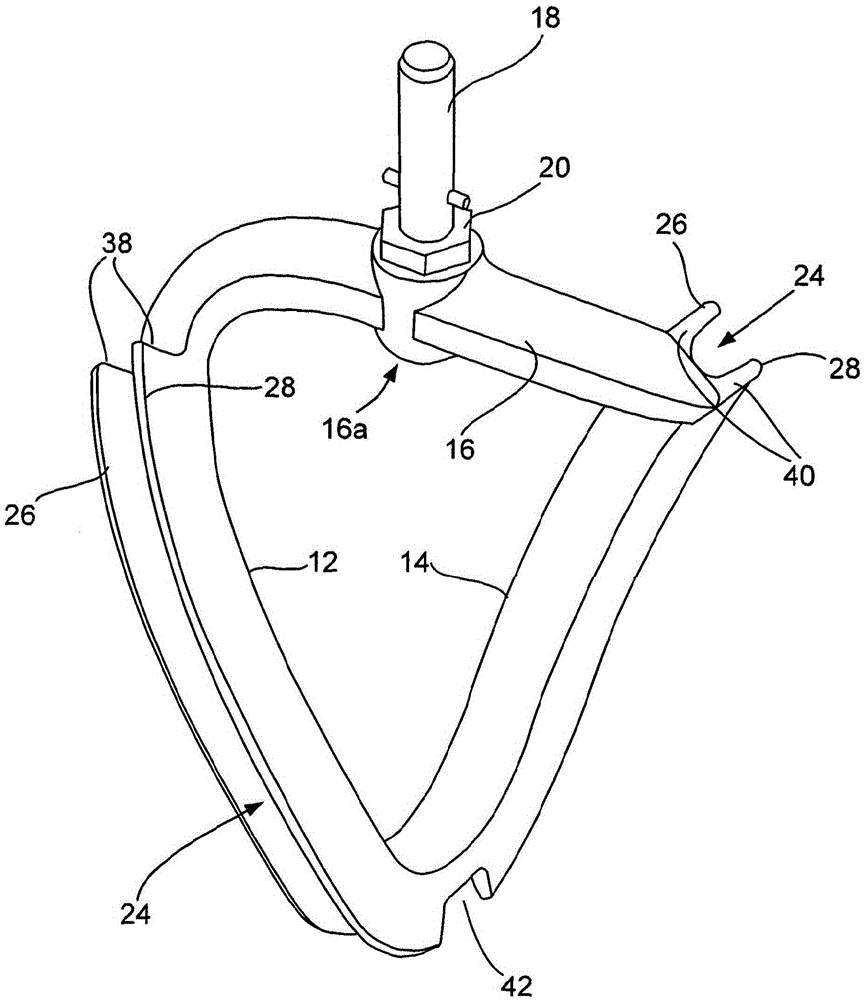

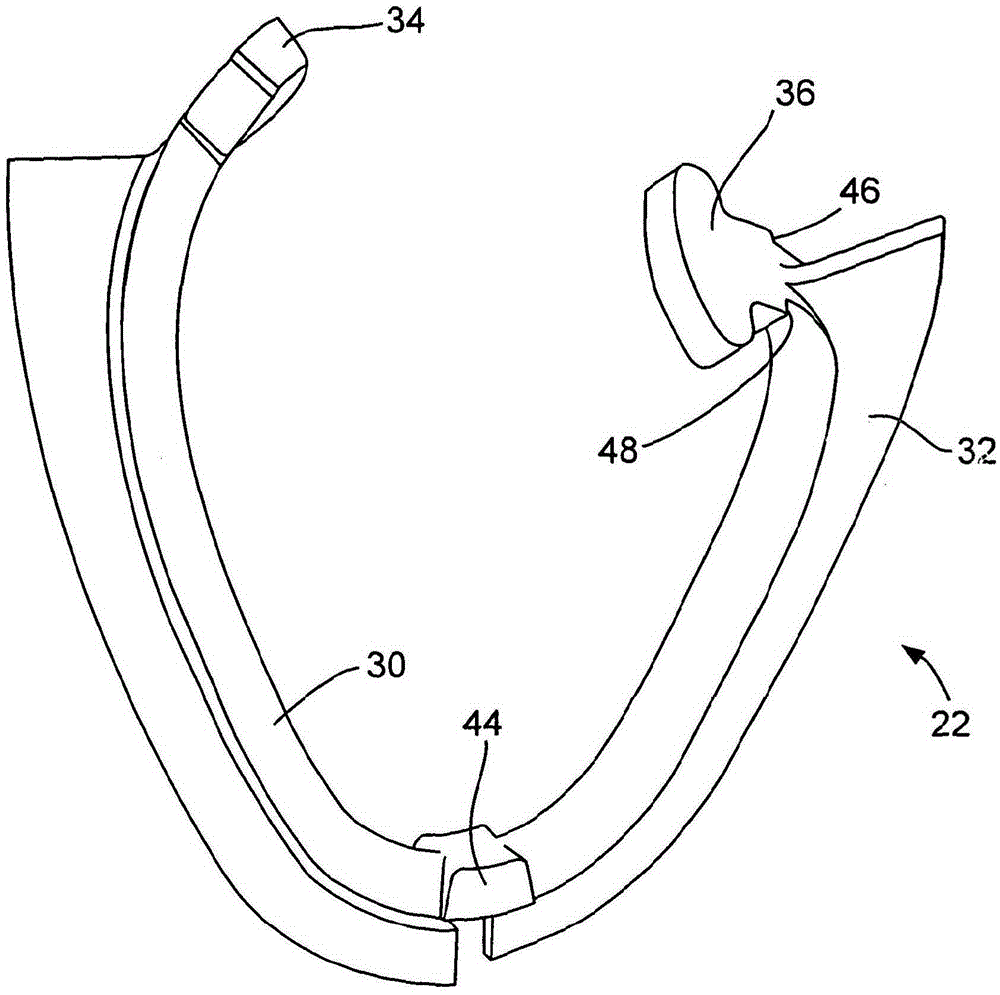

[0027] Referring now to the drawings, an agitator assembly according to one embodiment of the present invention is shown at 10 . As mentioned above, assembly 10 is intended for use in a vertical mixer (not shown) with a planetary drive. In this embodiment, the agitator assembly 10 includes a unitary frame formed by first and second arm members 12 and 14 and a cross member 16 . It will be appreciated that while it is convenient for the purposes of this description to refer to members 12, 14 and 16 as separate entities, they are in this embodiment (and indeed, preferably) made of a high strength plastic material such as a polymer or It is integrally formed of a metal material such as stainless steel.

[0028]The cross member 16 is provided with a threaded socket in its central region 16a; the socket is configured to accommodate a stub shaft 18 which is screwed into the threaded socket and held in place using a lock nut 20 . The shaft 18 is adapted at its free upper end to fit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com