Mechanical shock test fixture for integrated circuit

An integrated circuit and mechanical shock technology, which is applied in the field of integrated circuit mechanical shock test fixtures, can solve the problem that the fixture cannot be used for high-acceleration shock tests, and achieve the effect of simple replacement of the direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

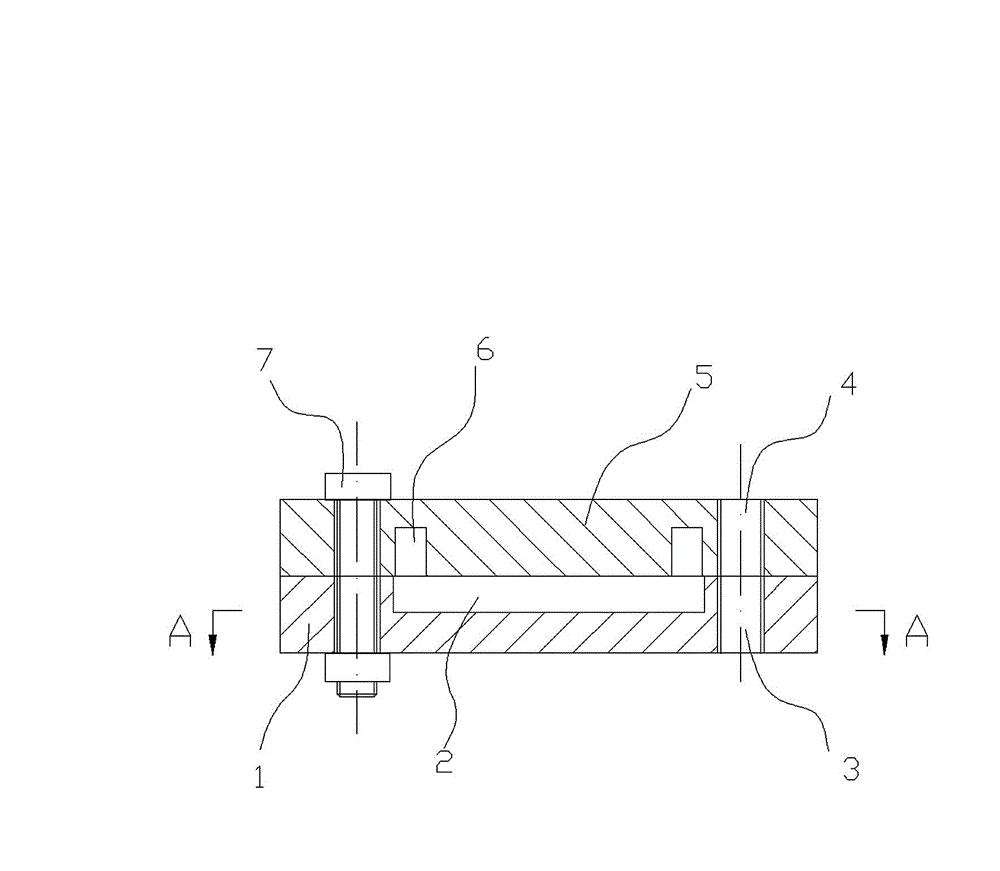

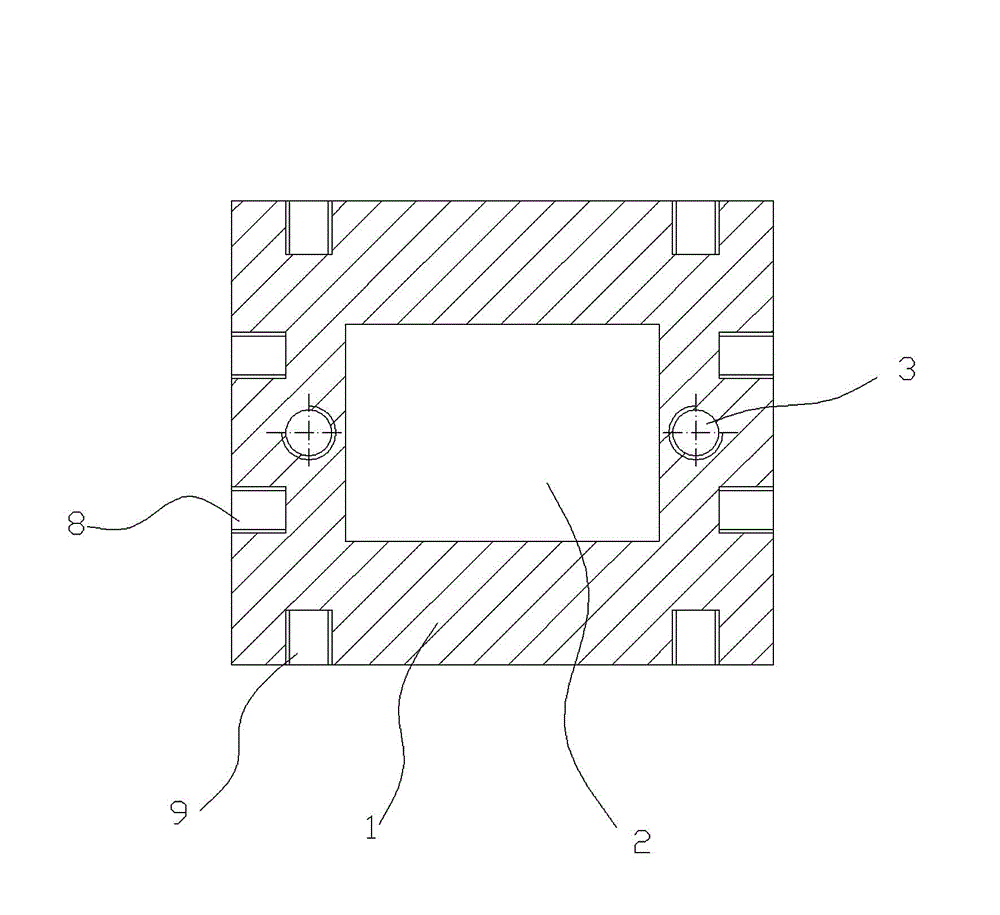

[0018] Such as figure 1 , figure 2 As shown, the integrated circuit mechanical impact test jig provided by the present invention comprises:

[0019] a. The base 1, the middle part of the base 1 is provided with a positioning groove 2 for holding the integrated circuit, the base 1 is provided with two bolt holes 3, and the side of the base 1 is respectively provided with an X-direction screw hole 8 and a Y-direction screw hole 9 ;

[0020] b. Cover plate 5, the middle part of the cover plate 5 is provided with a group of lead holes 6 matching with the positioning groove 2 in the base 1, and the cover plate 5 is provided with two bolt holes 4 matching with the base 1;

[0021] c. Cooperating bolts 7 are provided in the bolt holes on the base 1 and the cover plate 5 to connect the base 1 and the cover plate 5 together.

[0022] Working process of the present invention:

[0023] Such as figure 1 As shown, the integrated circuit is placed in the positioning groove 2 of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com