Dry Evaporator and Its Equilibrium Disturbance Device

A dry evaporator, fixed rod technology, applied in the direction of evaporator/condenser, heat exchanger shell, heat exchange equipment, etc., can solve the problems of low heat exchange efficiency and uneven amount of refrigerant, and achieve compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

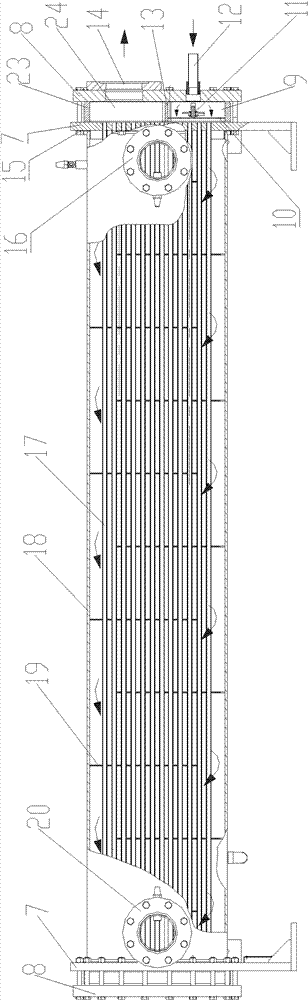

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

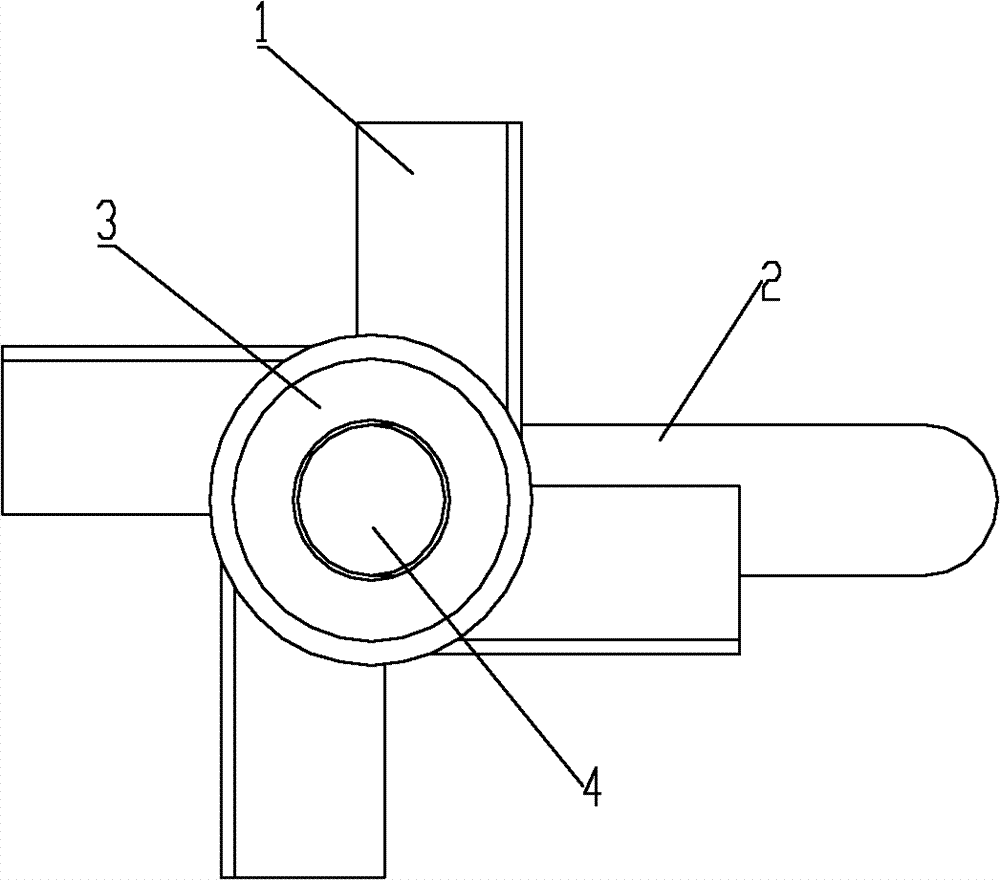

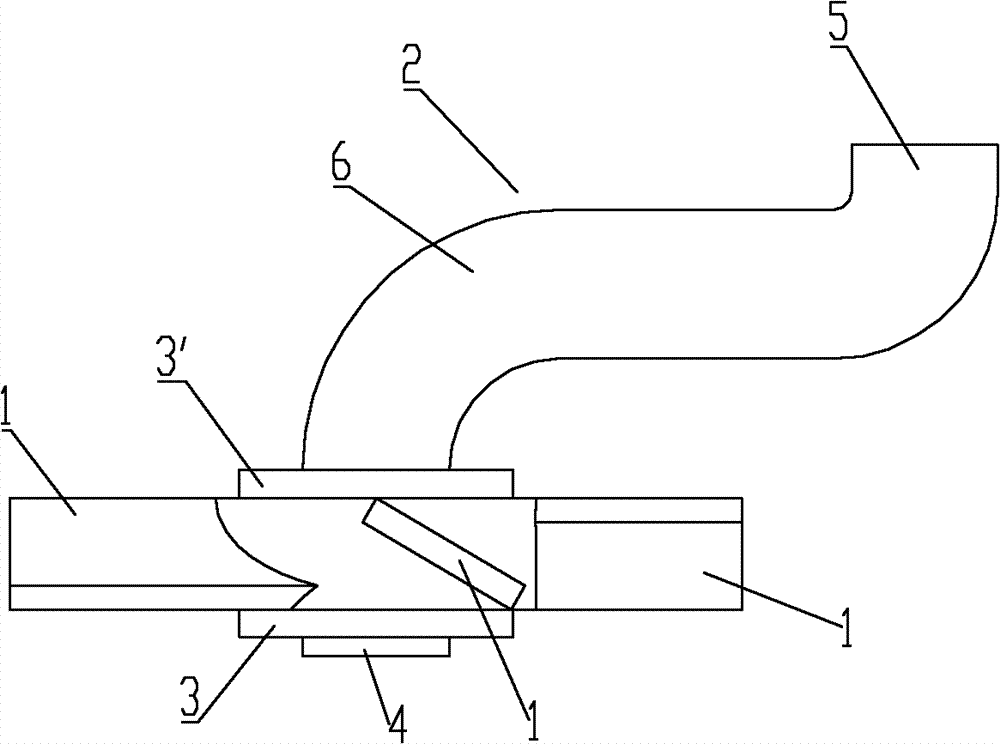

[0020] like Figure 1-2 As shown, the uniform disturbance device of the dry evaporator includes: a fixed rod 2 and an impeller; the impeller has a plurality of obliquely arranged blades 1 ; the impeller is pivotably arranged on the first end 4 of the fixed rod 2 . Through the above structure, during operation, since the blades on the impeller are arranged obliquely, there is a deflection angle between the blades and the flow direction of the refrigerant. When the refrigerant flows in from the refrigerant inlet pipe, the refrigerant has a certain impact on the blades. Force, and due to the existence of the deflection angle, the impeller starts to rotate, and the rotation of the impeller disturbs the refrigerant, thus destroying the characteristics of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap