Light-emitting diode

A technology of light-emitting diodes and light-emitting chips, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

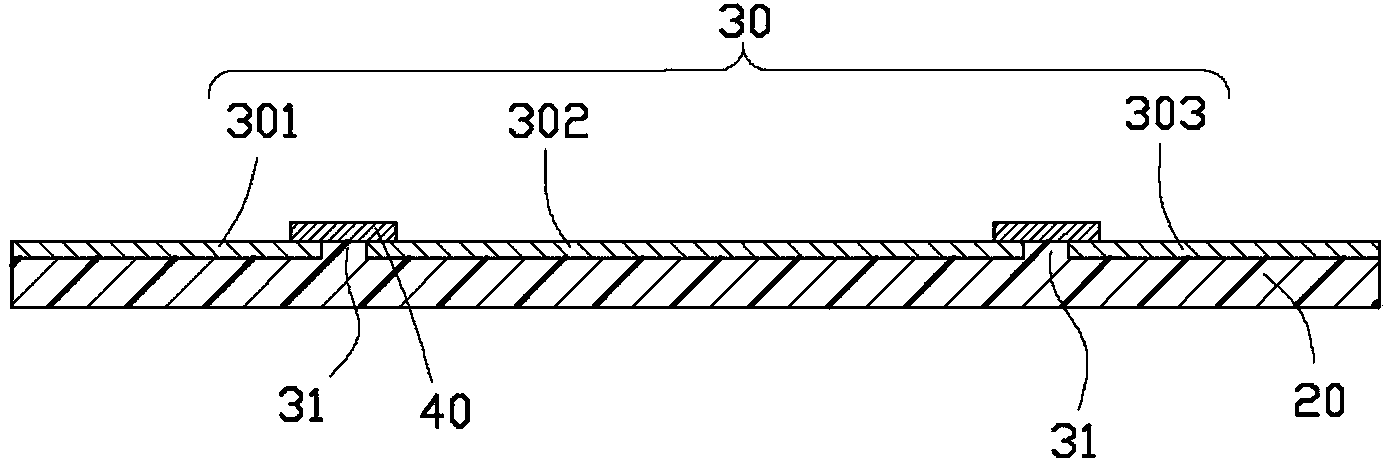

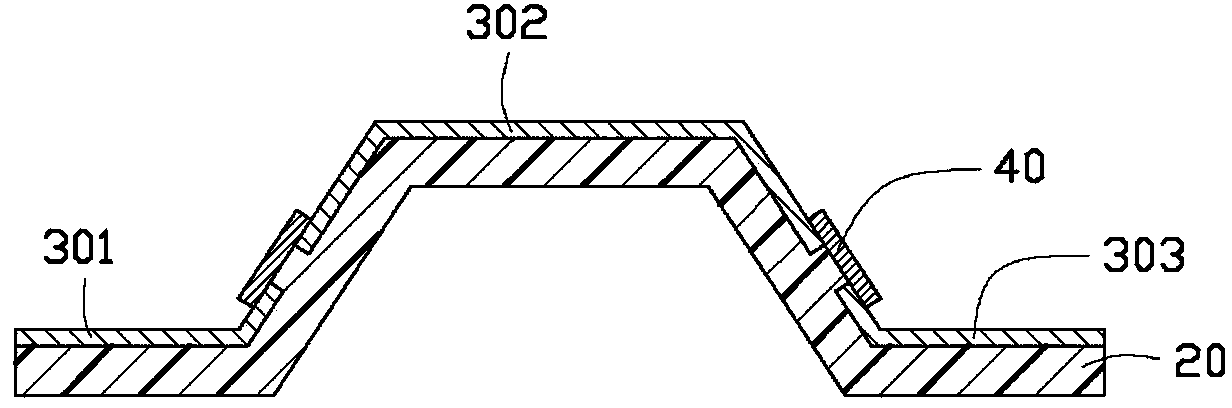

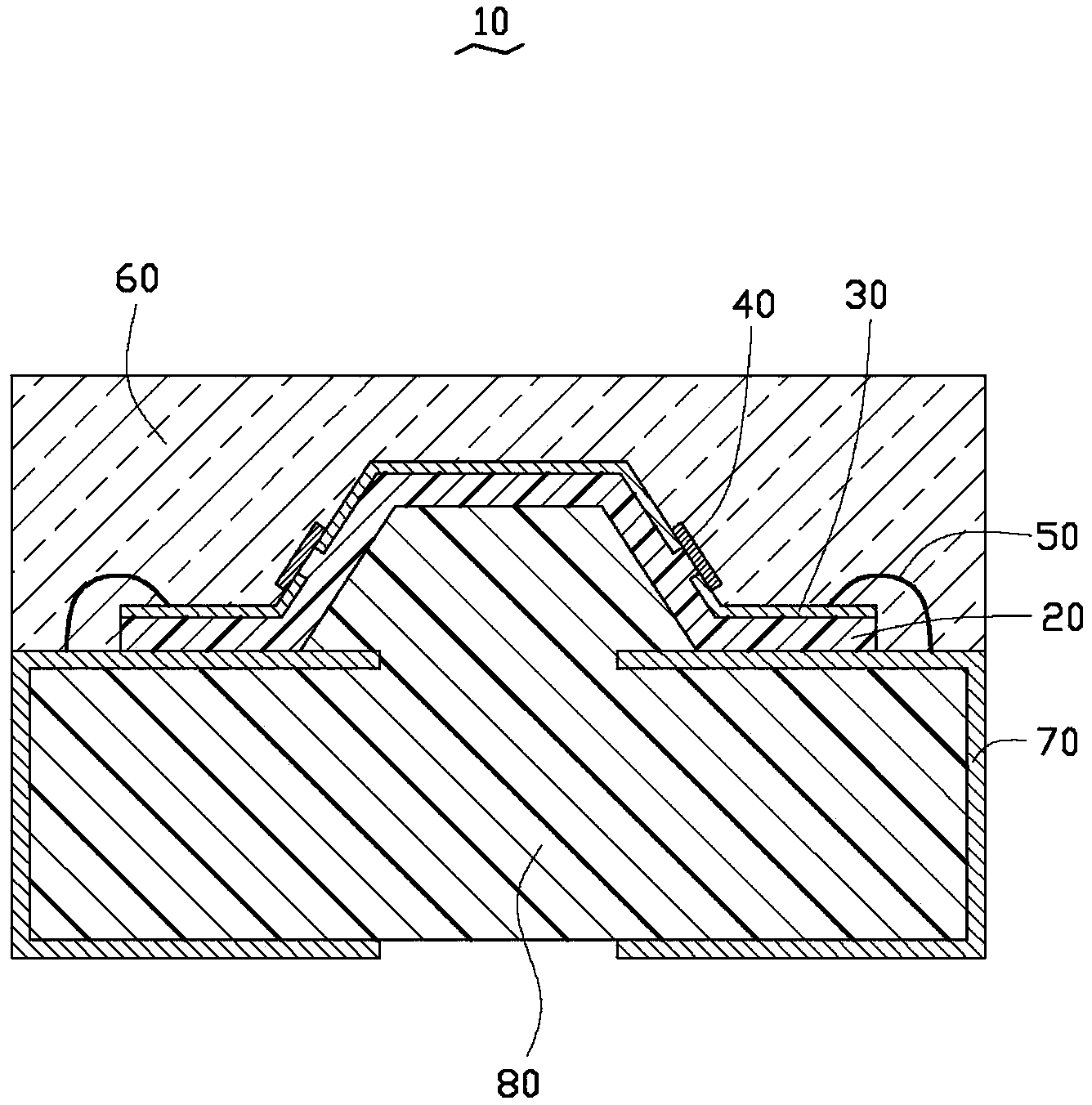

[0015] see Figure 1-3 , shows the light emitting diode 10 of the first embodiment of the present invention and two steps of its manufacturing process. The LED 10 includes a substrate 20 , a conductive plate set 30 , two light-emitting chips 40 , a package 60 , a base 80 , two conductive modules 70 , and wires 50 connecting the conductive plate set 30 and the conductive modules 70 .

[0016] The substrate 20 is a flexible substrate 20 which can be bent into a shape through processing. The conductive plate group 30 covers the substrate 20 and has openings 31 at distances from the left and right borders of the substrate 20 about a quarter of the total length of the substrate 20 . The opening 31 divides the conductive plate set 30 into a first conductive plate 301 , a second conductive plate 302 and a third conductive plate 303 from left to right. The conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com