Wind resistance braking devices and motor car body using same

A technology of wind resistance braking and car body, applied in the field of car braking, can solve the problems that cannot meet the braking needs of high-speed EMUs, etc., and achieve the effects of long service life, convenient installation and use, and good balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

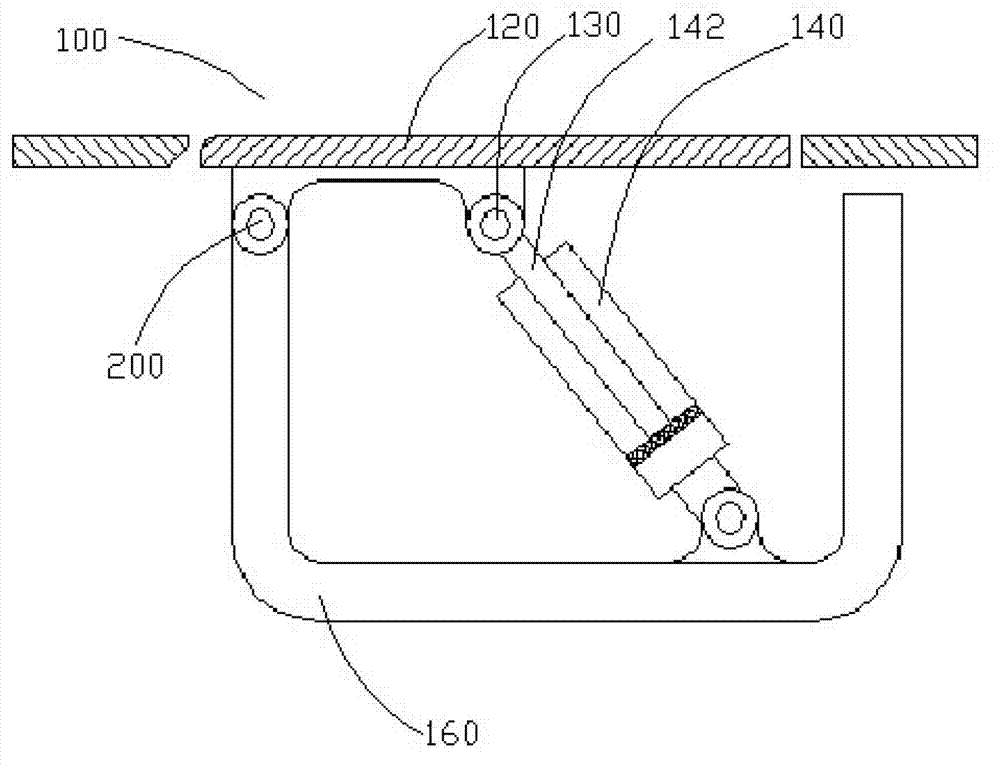

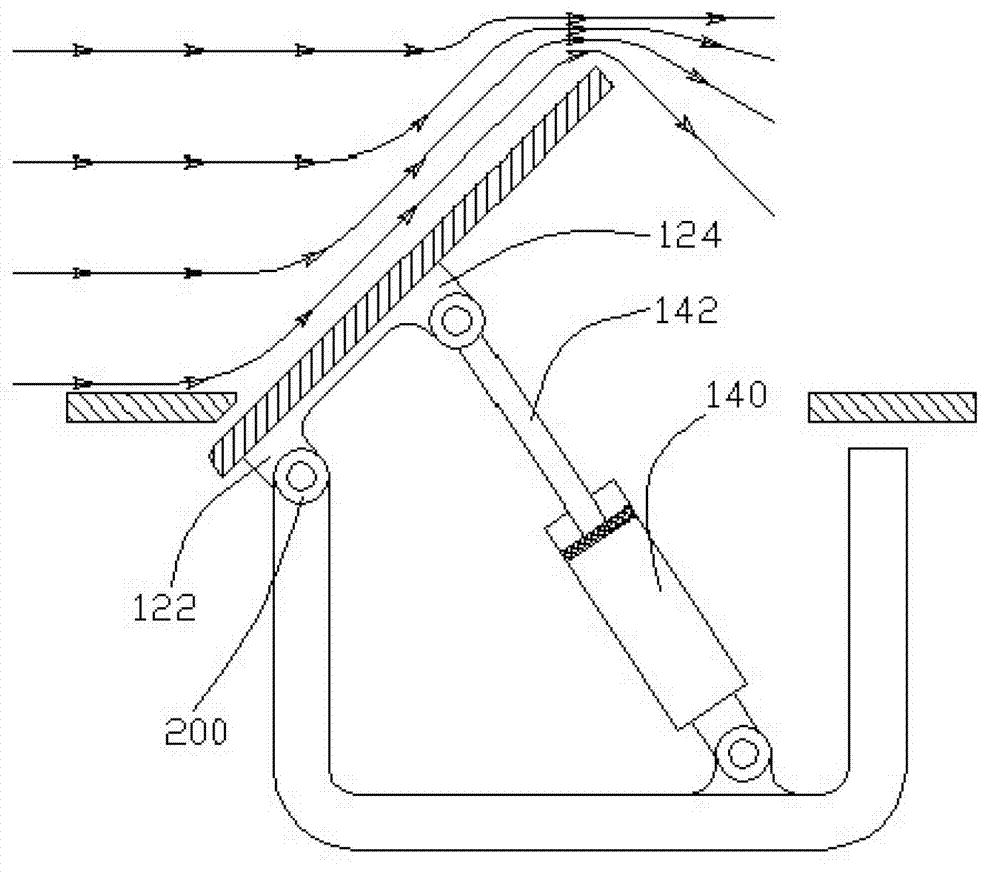

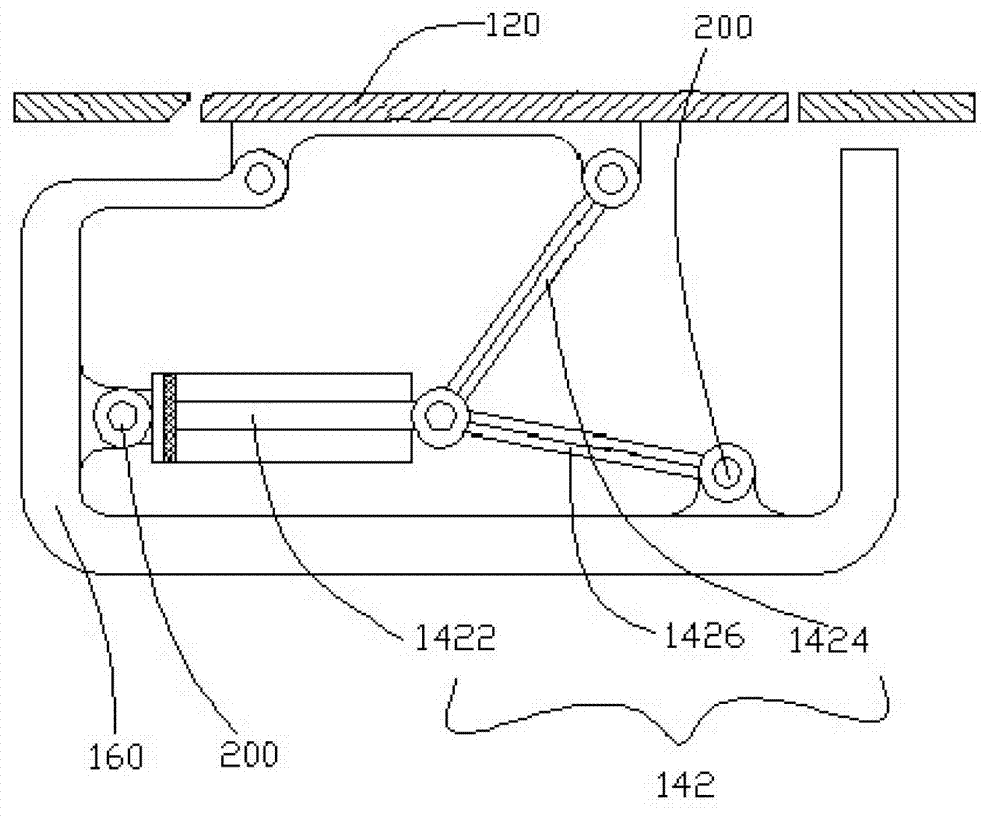

[0021] Such as figure 1 and as figure 2 As shown, a wind resistance brake device 100 includes a wind resistance brake plate 120 and a driving mechanism 140; the drive mechanism 140 includes a drive rod 142, and the drive rod 142 is hinged to the wind resistance brake plate 120; One end of the braking plate 120 is hinged to the fixing base 200 , and is driven by the driving rod 142 to rotate around the fixing base 200 .

[0022] Specifically, the windage braking plate 120 is provided with a mounting base, the mounting base includes a first mounting base 122 and a second mounting base 124, the first mounting base 122 is hinged to the fixing base 200, and the second mounting base 124 is hinged to the drive rod 142 . In this embodiment, the mounting seat and the windage brake plate 120 are integrally formed, so that the structure of the windage brake device 100 is simpler and the performance is safer.

[0023] It should be understood that the installation seat is provided to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com