Novel cloth guide roller

A cloth guide roller, a new type of technology, applied in textiles, textiles, papermaking, looms, etc., can solve the problems of low loom efficiency, unstable shutdown, easy damage to the burr of the licker roll, etc., to improve the efficiency of the loom. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

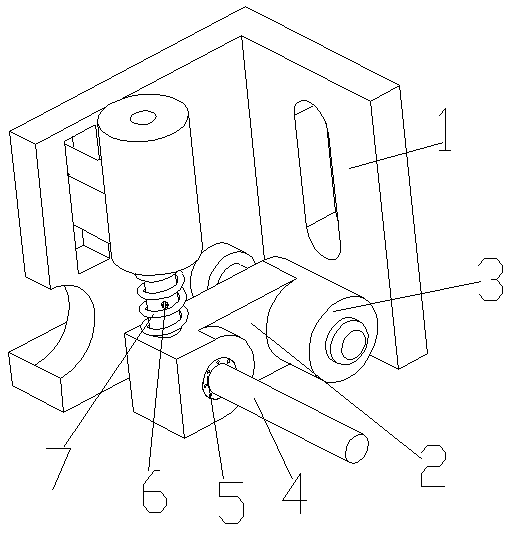

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 A new type of fabric guide roller according to the present invention is shown, which includes a support leg 1, a pressure spring 7, a swing support leg 2, and a cloth guide roller 4. The swing support leg 2 is connected to the support leg 1 through a pin shaft 3 On, can swing up and down, the said pressure spring 7 is fixed on the supporting foot 1 opposite to the pin shaft 3; the circumference surface of the pressure spring 7 is provided with an adjusting screw 6; the cloth guide roller 4 The bearing 5 is fixed on the supporting foot 1, and can rotate flexibly on the swinging supporting foot 2. The cloth guide roller 4 is covered with rubber rough surface. The thickness of the rubber rough surface is 1 mm.

[0014] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com