Device and method for improving yarn joint wear resistance

A wear-resistance and yarn technology, applied in the field of devices for improving the wear-resistance of yarn piecings, can solve problems such as the inability to guarantee the splicing effect of piecing, the unsuitable color spinning production process, and the failure to consider subsequent dyeing, etc. Simple operation, avoid warp stop or weft stop, ensure the effect of wear resistance and yarn body wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 provides a device for improving the wear resistance of yarn joints.

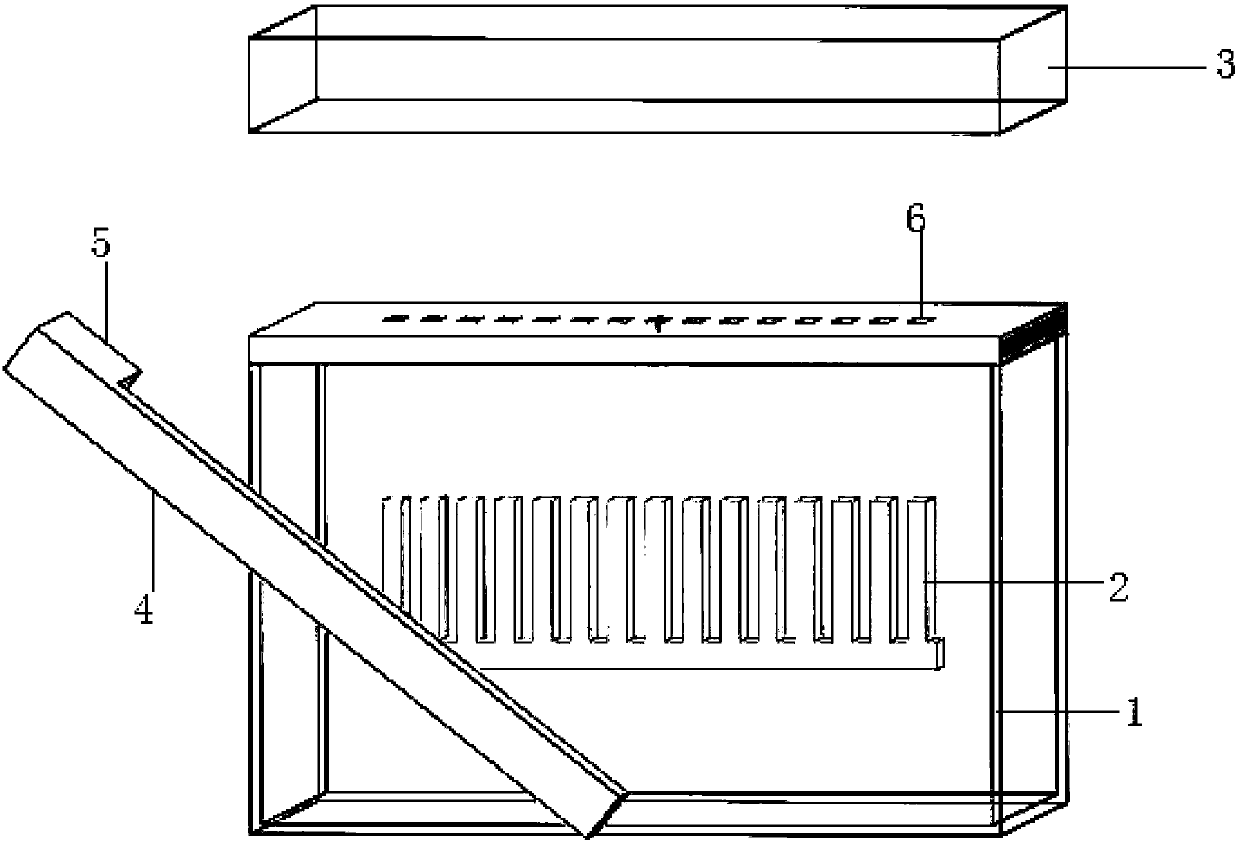

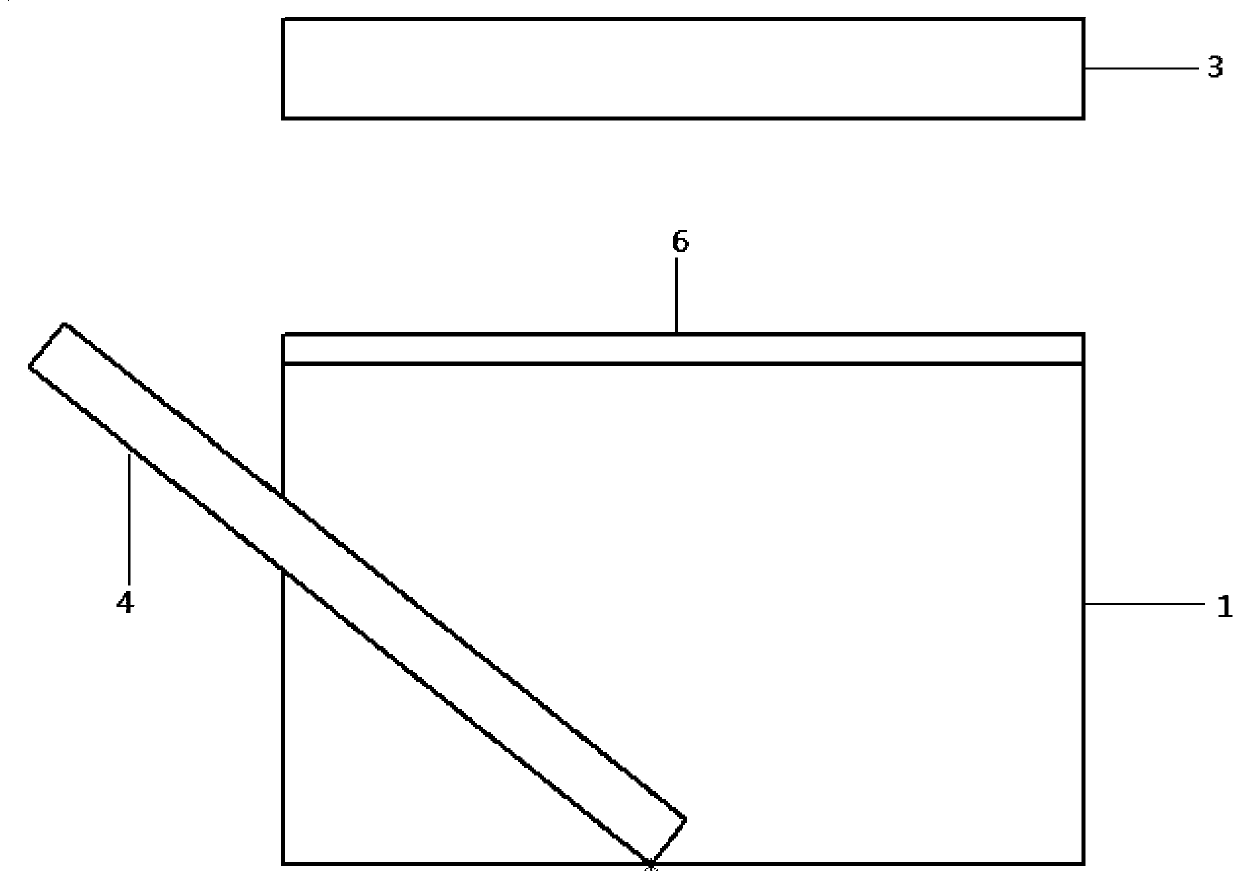

[0032] A device for improving the wear resistance of yarn joints, see figure 1 and figure 2 As shown, it includes a liquid storage tank 1, a movable needle plate 2, a heating component, a yarn clamping arm 4, a detection component, a first driving component that drives the movable needle plate 2 to move, a second driving component that drives the heating plate 3 to move, and The third driving part that drives the yarn clamping arm 4 to move, the detection component is a joint detector 5 or a photoelectric induction device, the joint detector 5 is connected to the end of the yarn clamping arm 4, and the liquid storage tank 1 There are a plurality of liquid outlets 6, and the plurality of liquid outlets 6 are distributed in columns, and there are intervals between adjacent liquid outlets 6; the glue in the liquid storage tank 1 is glue, hot melt adhesive , Slurry substances, cross-linkin...

Embodiment 2

[0040] This embodiment aims to provide a method for using the device for improving the wear resistance of yarn joints.

[0041] The device for improving the wear resistance of yarn joints is placed at the single spindle position of the winding machine. After the yarn joints are automatically knotted, the winding machine stops, and the yarn clamping arm 4 in the device for improving the wear resistance of yarn joints The joint detector 5 or the photoelectric sensor device connected to the end of the yarn clamping arm 4 confirms the position of the yarn joint, and pulls the yarn joint to the liquid outlet 6 above the liquid storage tank 1, and the movable needle plate 2 will be stained with The pin teeth of the glue are ejected to the upper surface of the liquid storage tank 1, and through the cooperation of the intermittent pin teeth and the liquid outlet 6, the glue is intermittently stuck to the joint of the yarn. After the feeding action is completed, the movable needle plate...

Embodiment 3

[0046] This embodiment aims to provide a method for using the device for improving the wear resistance of yarn joints.

[0047] The device for improving the wear resistance of yarn joints is placed at the single spindle position of the winding machine. After the yarn joints are automatically knotted, the winding machine stops, and the yarn clamping arm 4 in the device for improving the wear resistance of yarn joints The joint detector 5 or the photoelectric sensor device connected to the end of the yarn clamping arm 4 confirms the position of the yarn joint, and pulls the yarn joint to the liquid outlet 6 above the liquid storage tank 1, and the movable needle plate 2 will be stained with The pin teeth of the glue are ejected to the upper surface of the liquid storage tank 1, and through the cooperation of the intermittent pin teeth and the liquid outlet 6, the glue is intermittently stuck to the joint of the yarn. After the feeding action is completed, the movable needle plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com