Polyacetamide methylene maleate systhesis method

A technology of methylene maleate and a synthesis method, which is applied in the field of textile sizing, can solve the problems of uneven quality, uneven prices, and reduced loom efficiency, and achieves a suitable reaction mechanism, reduced reject rate, and improved loom efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Formula quantity: acetamide: 6g; hexamethylenetetramine: 6g; maleic anhydride: 5g; mineral acid: 0.7g; water: 65g.

[0015] Preparation Process:

[0016] (1) In the reaction kettle with jacket and reflux, put acetamide, water, hexamethylenetetramine and other substances specified in the formula, start stirring and steaming, and raise the temperature to 60°C;

[0017] (2) At 60°C, add inorganic acid as a catalyst, and react for 3 hours to generate cyclic acetamide hydroxymethyl derivatives;

[0018] (3) At 40°C, use one or several inorganic acids to convert the system H + Adjust the content to 3;

[0019] (4) At 120°C, add maleic anhydride dropwise, complete the dropwise addition within 0.5h, and control the temperature at 120°C;

[0020] (5) At 120°C, continue the heat preservation reaction until there is no residual monomer in the system;

[0021] (6) Cool down to room temperature to obtain textile auxiliaries.

Embodiment 2

[0023] Formula quantity: acetamide: 15g; hexamethylenetetramine: 15g; maleic anhydride: 20g; inorganic acid: 5g; water: 85g

[0024] Preparation Process:

[0025] (1) In the reaction kettle with jacket and reflux, put acetamide, water, hexamethylenetetramine and other substances specified in the formula, start stirring and steaming, and raise the temperature to 90°C;

[0026] (2) At 90°C, add inorganic acid as a catalyst, and react for 3 hours to form a cyclic acetamide hydroxymethyl derivative;

[0027] (3) At 65°C, use one or several inorganic acids to convert the system H + Adjust the content to 6;

[0028] (4) At 150°C, add maleic anhydride dropwise, complete the dropwise addition within 3 hours, and control the temperature at 150°C;

[0029] (5) At 150°C, continue the heat preservation reaction until the system no longer has residual monomers;

[0030] (6) Cool down to room temperature to obtain textile auxiliaries.

Embodiment 3

[0032] Formula quantity: acetamide: 10g; hexamethylenetetramine: 10g; maleic anhydride: 13g; inorganic acid: 2.5g; water: 75g.

[0033] Preparation Process:

[0034] (1) In the reaction kettle with jacket and reflux, put acetamide, water, hexamethylenetetramine and other substances specified in the formula, start stirring and steaming, and raise the temperature to 75°C;

[0035] (2) At 75°C, add inorganic acid as a catalyst, and react for 3 hours to generate a cyclic acetamide hydroxymethyl derivative;

[0036] (3) At 55°C, use one or several inorganic acids to convert the system H + Adjust the content to 4;

[0037] (4) At 130°C, add maleic anhydride dropwise, complete the dropwise addition within 0.5-3 hours, and control the temperature at 135°C;

[0038] (5) At 135°C, continue the heat preservation reaction until there are no more residual monomers in the system;

[0039] (6) Cool down to room temperature to obtain textile auxiliaries.

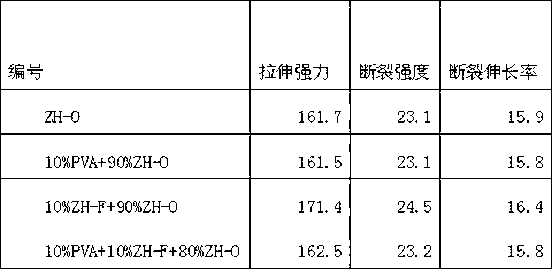

[0040] In the production proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com