Coated fabric slurry conversion device

A conversion device, technology of coated fabrics, applied in the direction of processing textile material equipment configuration, mixer with rotating stirring device, textile material processing, etc., can solve problems not mentioned, etc., achieve reasonable structure, clean conversion, overcome Effect of Coating Quality Issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

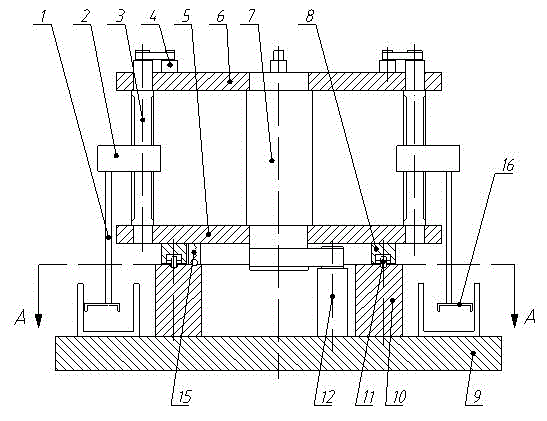

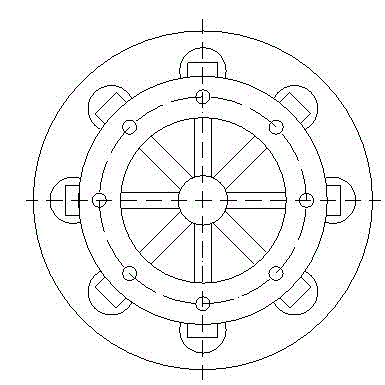

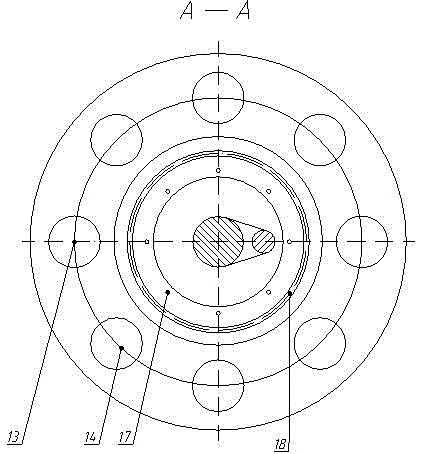

[0022] See attached figure 1 , figure 2 , image 3 , a fast conversion device for functional coating fabric slurry, including a base 9, a mixing tank 14, a cleaning tank 13, a guide rail mounting ring 10, and a large motor 12 are arranged on the base 9, wherein the mixing tank 14 and the cleaning tank 13 are arranged alternately On the outer periphery of the base 9, the guide rail mounting ring 10 is arranged on the inner side of the mixing bucket 14 and the cleaning bucket 13, the large motor 12 is arranged on the inside of the guide rail mounting ring 10, the guide rail mounting ring 10 is provided with a guide rail groove 18 and a positioning groove 17, and the guide rail mounting ring 10 A moving guide rail 8 is installed on the upper side, and a roller 11 is installed on the moving guide rail 8. A locking mechanism 15 composed of a spring and a ball is installed on the inner side of the moving guide rail 8. The lower bracket plate 5 is installed on the moving guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com