Quick conversion device of functional coated fabric slurry

A coated fabric and fast switching technology, which is applied in the processing of textile materials equipment configuration, textile material processing, textiles and papermaking, etc., can solve the problems of inconsistent local liquid level, easily polluted pulp, uneven coating, etc. , to achieve the effect of overcoming coating quality problems, improving mixing uniformity, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

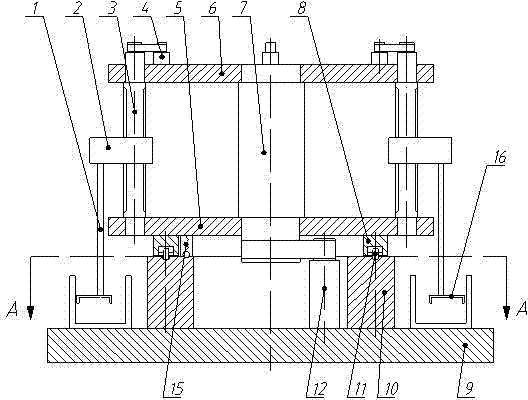

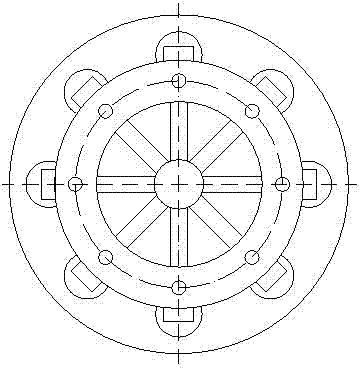

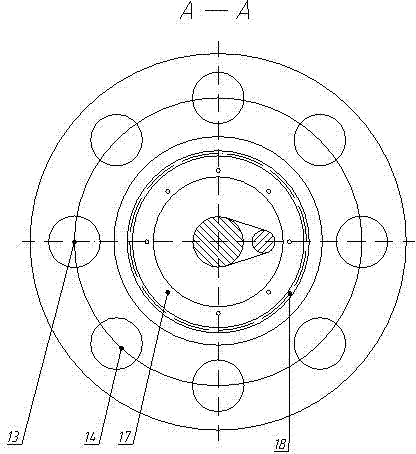

[0021] See attached figure 1 , 2 , 3, a kind of quick conversion device of functional coating fabric slurry, comprises base 9, is provided with mixing bucket 14, cleaning bucket 13, guide rail mounting ring 10, large motor 12 on the base 9, wherein mixing bucket 14 and cleaning bucket 13 are interlaced are distributed on the outer periphery of the base 9, the guide rail installation ring 10 is arranged on the inner side of the mixing bucket 14 and the cleaning bucket 13, the large motor 12 is arranged on the inside of the guide rail installation ring 10, and the guide rail installation ring 10 is provided with a guide rail groove 18 and a positioning groove 17, and the guide rail installation A moving guide rail 8 is installed on the ring 10, and a roller 11 is installed on the moving guide rail 8. A locking mechanism 15 composed of a spring and a ball is installed on the inner side of the moving guide rail 8. The lower bracket plate 5 is installed on the moving guide rail 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com