Device for cooling guiding device group of turbine

A technology for cooling turbines and guides. It is used in the cooling of engines, cooling of turbines/propulsion devices, and engine components. It can solve the problems of blades affecting service performance and service life, and achieve the purpose of relieving cracks and improving performance and service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

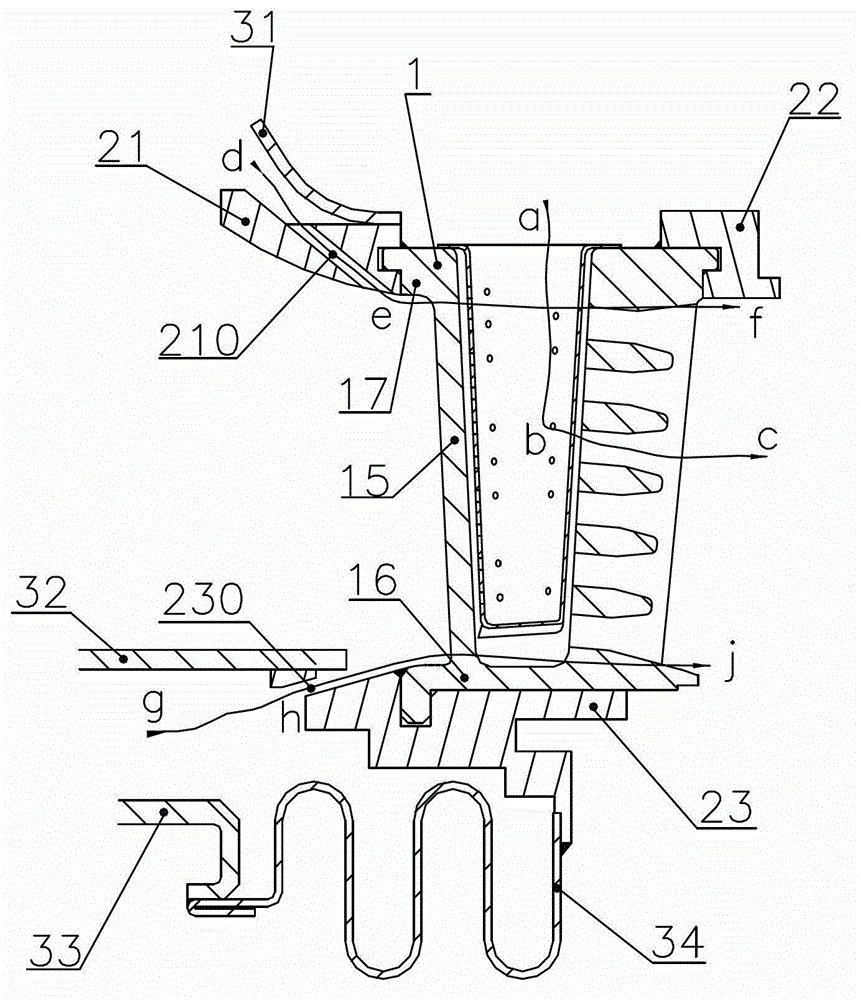

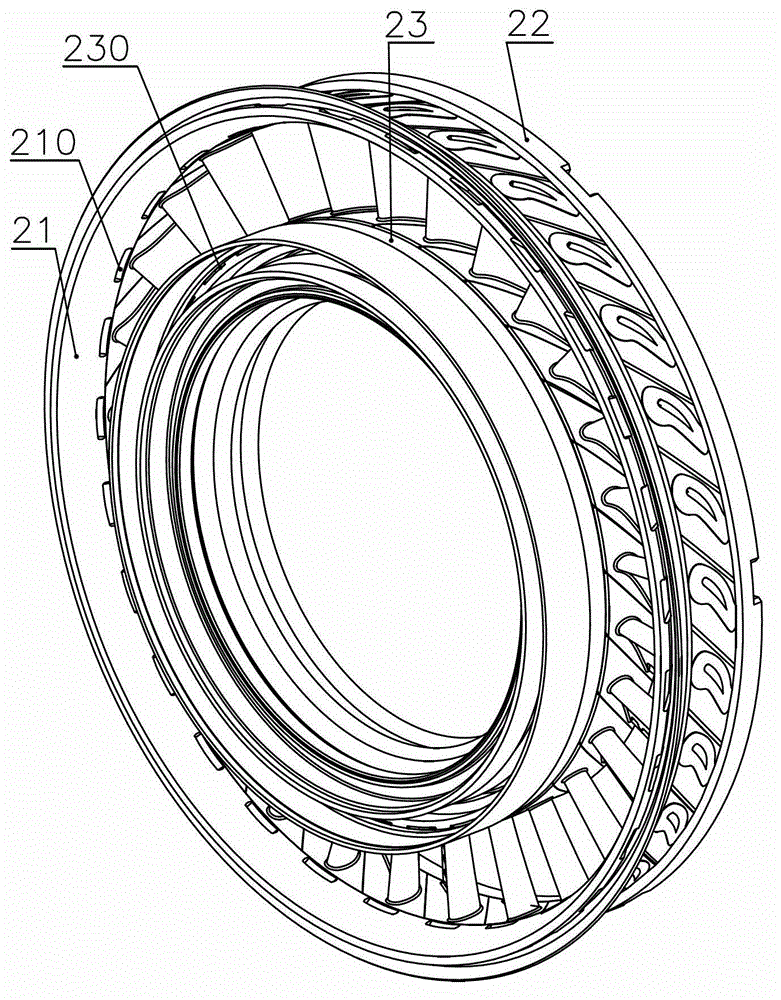

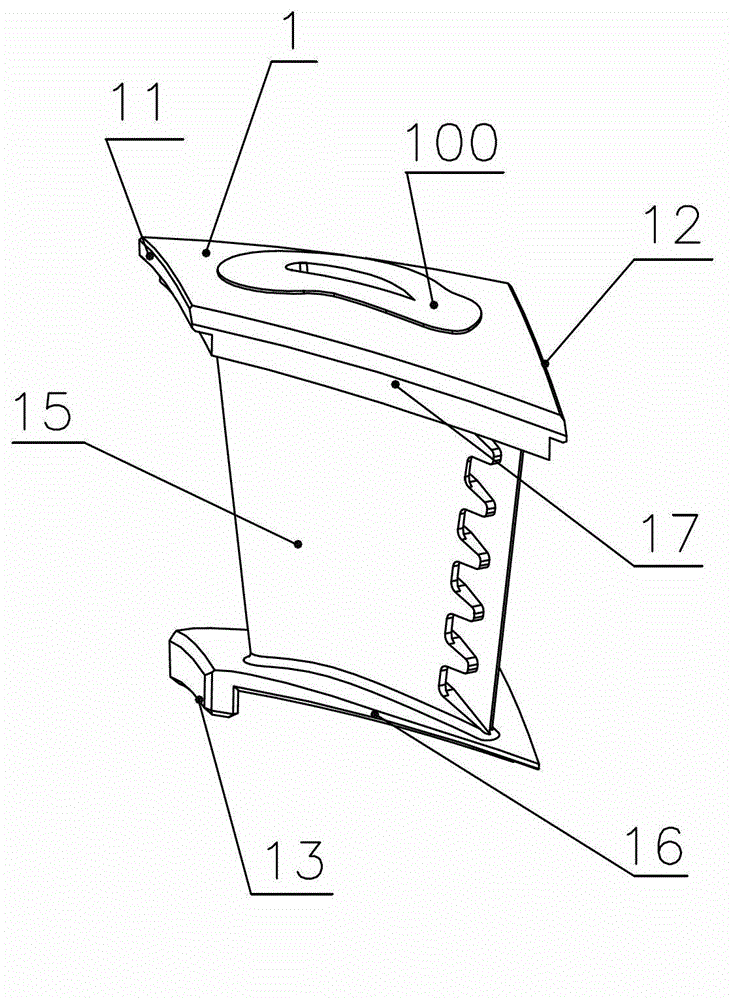

[0022] see figure 1 and figure 2 , the present invention provides a device for cooling a turbine guider group, comprising a plurality of guide vane assemblies 1, a first outer edge plate mounting ring 21 with annular grooves respectively opened on the side ends, a second outer edge plate mounting ring 22 and An inner edge plate mounting ring 23 with an annular groove is opened on the periphery. Among them, a plurality of guide vane assemblies 1 are evenly distributed around the inner edge plate installation ring 23, and the two side ends of the guide vane assembly 1 are sleeved in the first outer edge plate installation ring 21 and the second outer edge plate installation ring respectively in the axial direction. 22 ring grooves.

[0023] combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com