Preparation method of anti-oxidation coating on surface of C/C composite material

An anti-oxidation coating and composite material technology, applied in the field of protective materials, can solve the problems of unhealable coating cracks and pores, achieve excellent anti-oxidation performance, reduce the generation and spread of oxidative stress, and relieve thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method for an anti-oxidation coating on the surface of a C / C composite material, comprising the following steps:

[0024] Step 1. Polish the C / C composite material with sandpaper, ultrasonically clean it with absolute ethanol for 20-40 minutes, and then dry it in an oven at 70-100°C for 0.5-1 hour.

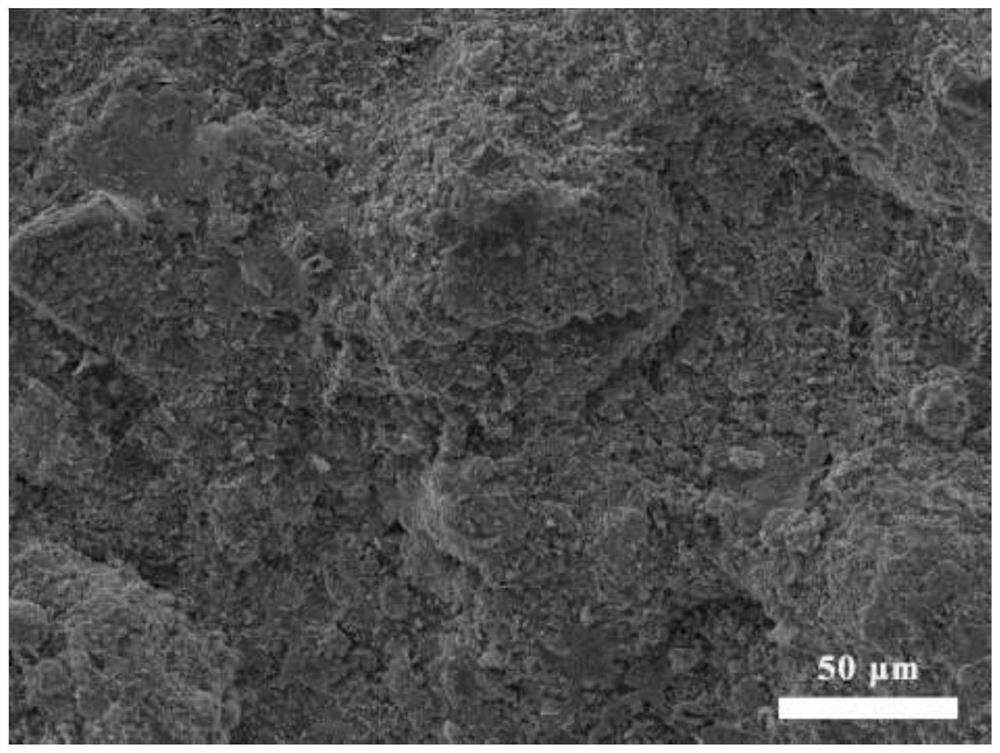

[0025] Step 2, using an embedding method to embed a SiC coating on the surface of the C / C composite material to obtain a C / C composite material protected by the SiC coating;

[0026] Specifically, 65%-85% Si powder, 8%-16% C powder, 7%-19% Al 2 o 3 The powders are mixed and placed in a resin ball mill jar, and mixed for 2-4 hours to obtain embedding powders. Embed the C / C composite material into the embedding powder in the graphite crucible, place the graphite crucible in a high-temperature graphitization heat treatment furnace, use Ar as the protective gas, and raise the temperature to 1900-2100°C at 8-10°C / min , heat preservation for 1-2h, and naturally c...

Embodiment 1

[0031]Step 1. Polish the C / C composite material with sandpaper, ultrasonically clean it with absolute ethanol for 25 minutes, and then dry it in an oven at 80°C for 1 hour;

[0032] Step 2. Mix 70 g of Si powder, 15 g of C powder, and 10 g of SiC powder, put them in a resin ball mill jar, and mix for 3 hours to obtain embedding powder. Embed the C / C composite material into the embedding powder in the graphite crucible, place the graphite crucible in a high-temperature graphitization heat treatment furnace, use Ar as the protective gas, raise the temperature to 1900°C at 8°C / min, and keep it for 2h. Cool naturally to normal temperature to obtain C / C composite material protected by SiC coating;

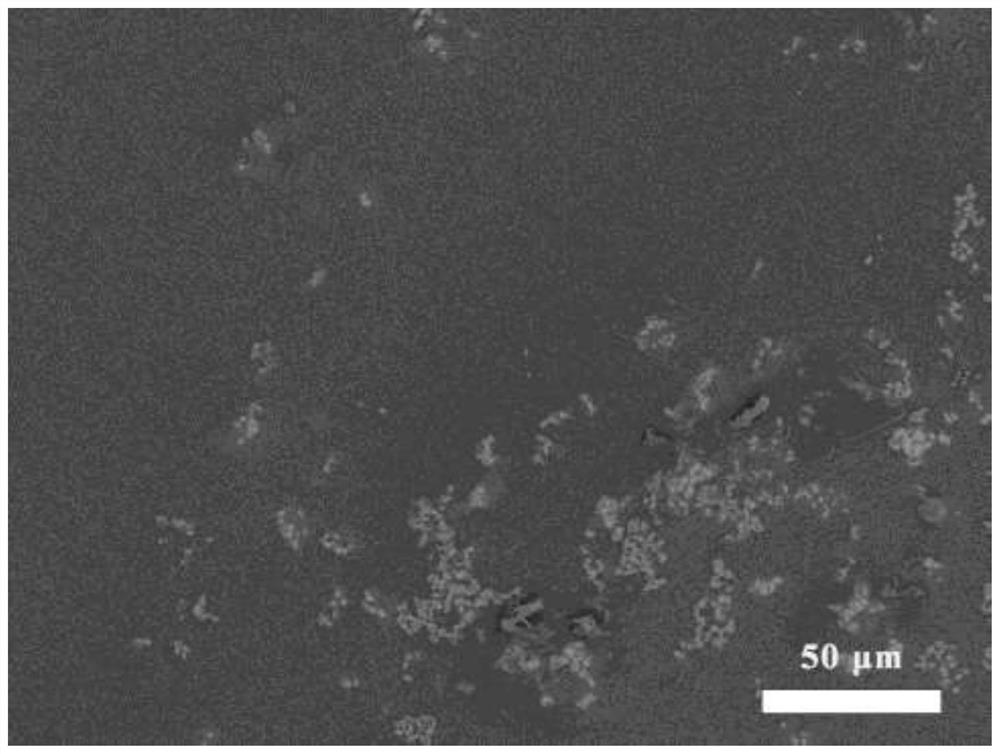

[0033] Step 3, 80gZrSi 2 , 20g of SiC powder was mixed uniformly by planetary ball mill wet grinding method to obtain a mixed powder; 45g of mixed powder, 6g of binder, and 49g of distilled water were mixed and stirred for 2 hours to obtain a mixed slurry; the mixed slurry was granulat...

Embodiment 2

[0035] Step 1. Polish the C / C composite material with sandpaper, ultrasonically clean it with absolute ethanol for 35 minutes, and then dry it in an oven at 80°C for 1 hour;

[0036] Step 2. Mix 75g of Si powder, 12g of C powder, and 13g of SiC powder, put them in a resin ball mill jar, and mix for 3.5 hours to obtain embedding powder. Embed the C / C composite material into the embedding powder in the graphite crucible, place the graphite crucible in a high-temperature graphitization heat treatment furnace, use Ar as the protective gas, raise the temperature to 2000°C at 9°C / min, and keep it for 2h. Cool naturally to normal temperature to obtain C / C composite material protected by SiC coating;

[0037] Step 3, 70gZrSi 2 , 30g of SiC powder was uniformly mixed by planetary ball mill wet grinding method to obtain a mixed powder; 44g of mixed powder, 5g of binder, and 51g of distilled water were mixed and stirred for 2 hours to obtain a mixed slurry; the mixed slurry was granulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com