Integrally-formed combined pipe fitting manufacturing method

A manufacturing method and technology for pipe fittings, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of limited effect of frame shape fluency, uneven thickness, thickening of pipe wall thickness, etc., and achieve easy expansion and change. , smooth shape, small shape variability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

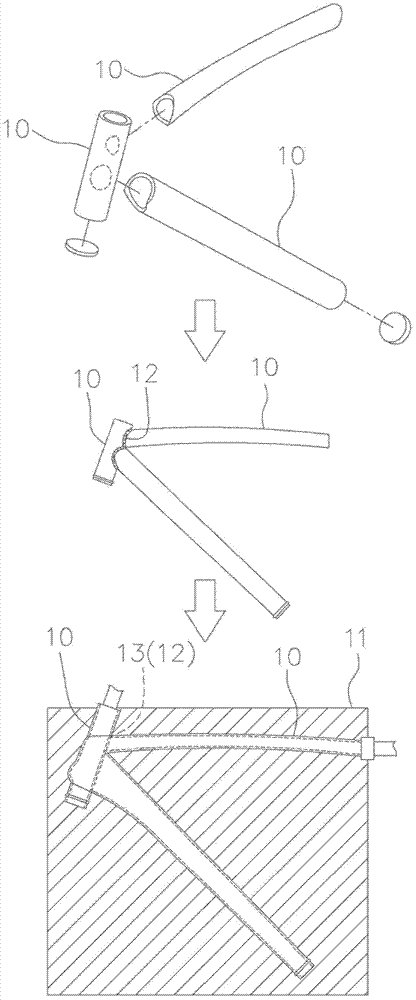

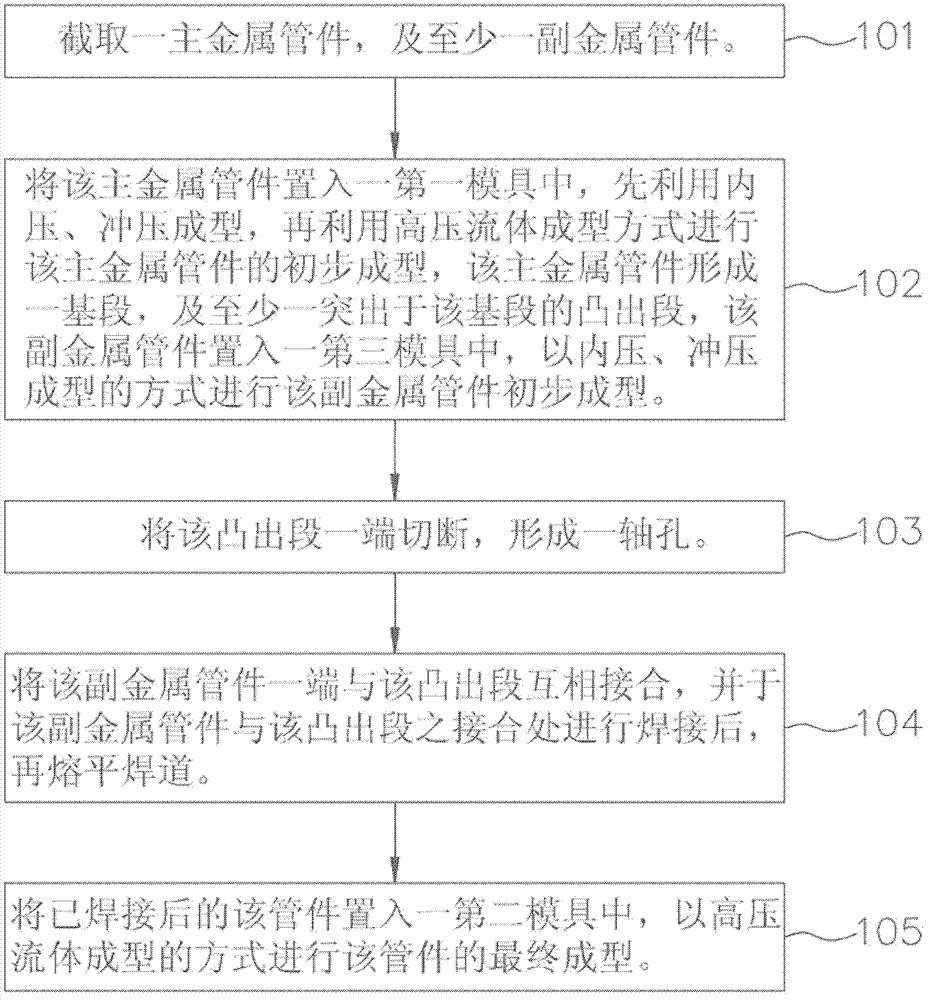

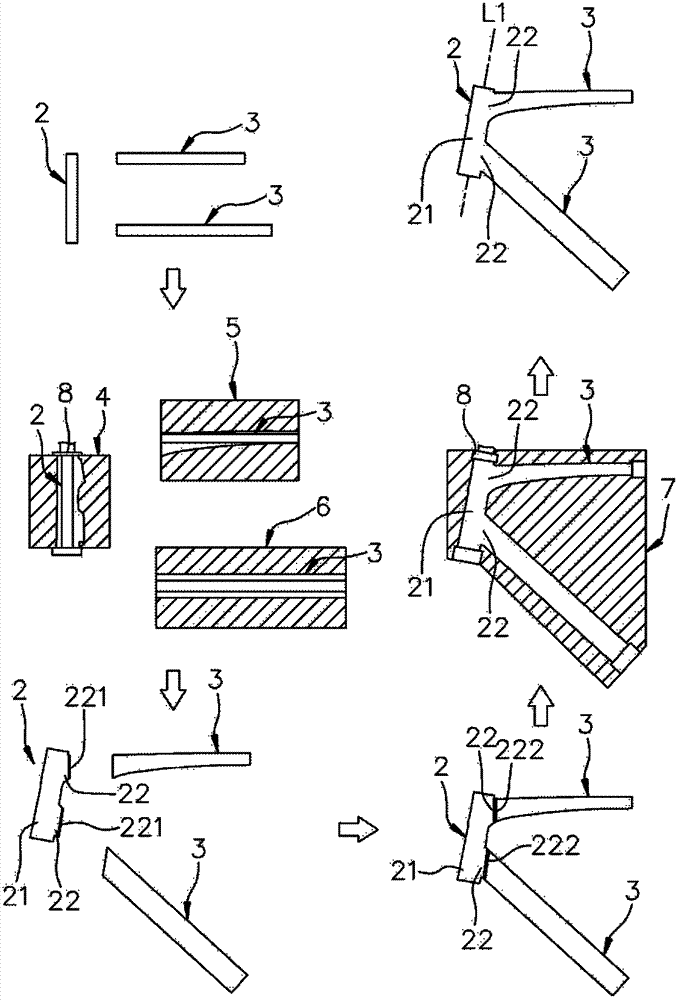

[0031] refer to figure 2 and image 3 , the first preferred embodiment of the manufacturing method of the integrally formed composite pipe fitting of the present invention comprises the following steps:

[0032] Step 101: Cutting out one main metal pipe 2 and two auxiliary metal pipes 3 . The material used for the main metal pipe 2 and the aforementioned auxiliary metal pipe 3 is aluminum alloy.

[0033] Step 102: Put the main metal pipe fitting 2 into a first mold 4, first use internal pressure and stamping to form, and then use high-pressure fluid forming to perform preliminary molding of the main metal pipe fitting 2, so that the main metal pipe fitting 2 is formed into a A base section 21, and two protruding sections 22 protruding from the base section 21. The aforementioned auxiliary metal pipe fittings 3 are placed into a third mold 5 and a fourth mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com